What is PVQ steel plate could also say — What is pressure vessel quality steel?

So, what is PVQ steel plate exactly? PVQ is an acronym for Pressure Vessel Plate Quality. That means any steel plate using this designation is designed for use in pressure vessels. These pressure vessels are normally some type of closed container meant to hold any gas or liquid that is held at a pressure much different than its surrounding ambient pressure.

PVQ steel plate using for the production of pressure vessels, which closed containers designed to hold gases or liquids at a pressure substantially different than the ambient pressure.

Due to the high potential for dangerous accidents in the event of material failure. PVQ steel plate must meet specific composition and material properties. In particular, temperature thresholds play important roles in PVQ material.

PVQ is often available in as-rolled, as well as normalized conditions. Normalization increases the ductility and notch toughness of material. (Or, the ability to absorb energy despite a material flaw).

Build your PVQ steel plate quote today or contact a member of our experienced team to place an order.

Both of which are ideal attributes for pressure vessel manufacturers and engineers. While similar, this process is slightly different than other heat treatments, such as quenched and tempering.

Pressure Vessel Quality (PVQ) steel plate use to produce pressure vessels due to its tensile strength, notch toughness, ductility and fatigue characteristics. Before examining the properties of PVQ grades, here are a few terms used to describe the properties of steel, defined:

Strength:

the load the steel can bear. Yield point and tensile strength determined the steel strength. A yield point is the point at which a material is stressed to the point where it deforms but does not break. Tensile strength is the amount of stress needed for the material to break.

Notch Toughness:

the level of impact steel can absorb before denting, typically measured by a Charpy Impact test.

Ductility:

the capability of a material, stretched out before it becomes weak or brittle. Elongation determined the Ductility measured, which is the percent the length of a stretched material increases before it breaks. Each of these properties impacts the applications and use of PVQ plate. And their influence on the use of primary PVQ grades will explored below.

Benefits of Using PVQ Plate

It didn’t take engineers long to realize the advantages of using the PVQ grades not just in pressure vessels. But also in any other design requiring higher strengths. Better “toughness” (as defined by Charpy V-Notch testing), and better grain structure resulting in superior Ultra Sound Testing results. These applications include turbine manufacturing, compressors, heat exchangers, and virtually hundreds of other applications. This is why IBC Group carries A516 through 14″ thick, and A387 through 8″ thick.

Please contact us today with any questions regarding PVQ steel plate grades and how they can benefit your company. IBC have many customers that now specify A516 over A36 because of its superior grain structure and better physical strengths. We can burn all thicknesses to any shape or saw cut for flat bar applications. Looking forward to assisting you with any of your PVQ steel plate requirements.

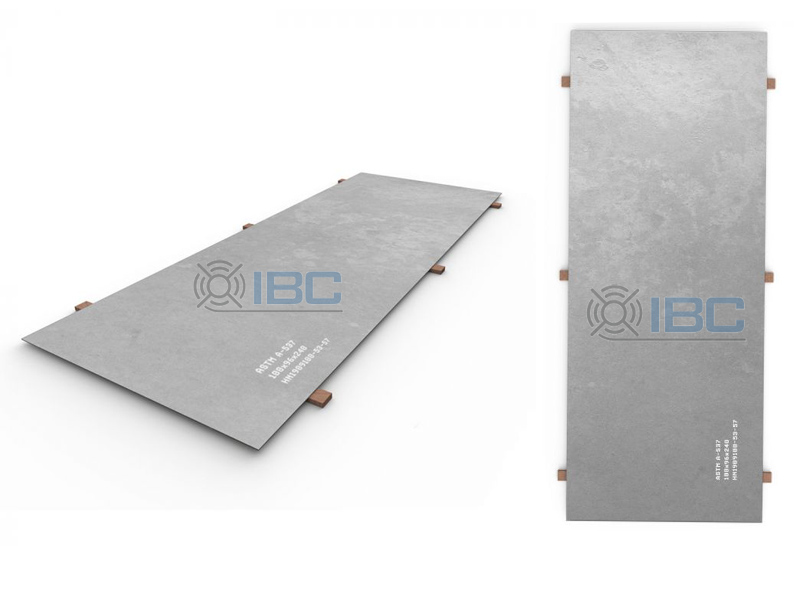

IBC Group supplies both common and specialty PVQ steel plate that meets American and European specification standards to clients across the country and around the globe.

IBC Group also provides complete product documentation with every purchase, which includes chemical composition and material property test results where applicable. Our trusted supply chain and strategically located distribution centers ensure we can provide you with the PVQ steel plate material you need when you need it.

Contact with IBC Metal Group Today!