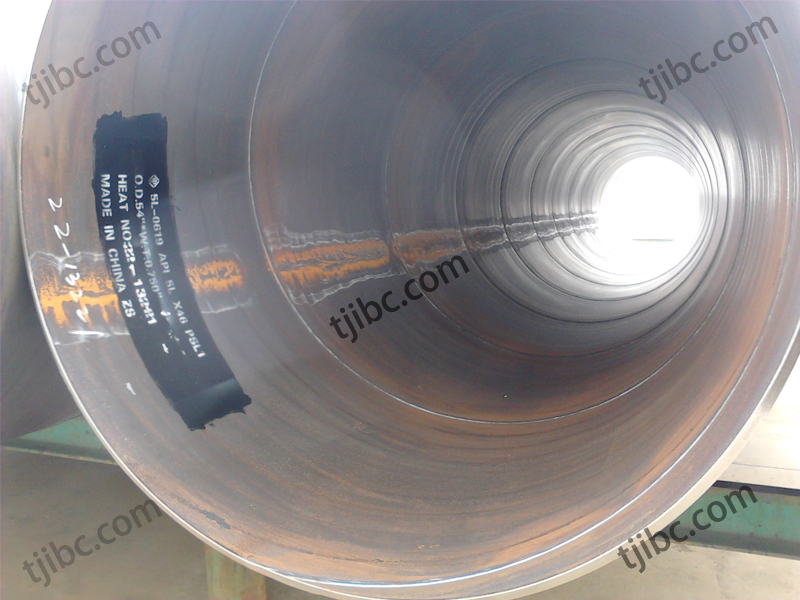

Spiral welded steel pipe: the low-carbon carbon structural steel or low alloy structural steel is rolled into a tube blank according to a certain spiral Angle, and then the tube joint is welded. It can produce large diameter steel pipes from narrow strips.

Advantages and Disadvantages

(1) The size is accurate, the general diameter tolerance does not exceed 0.12%, the deflection is less than 1/2000, the ellipticity is less than 1%, and the sizing and straightening process can be generally eliminated.

(2) can be continuous production, theoretically can produce infinite length steel pipe, cutting head, cutting tail loss is small, can improve the metal utilization rate of 6% ~ 8%.

(3) Compared with the straight seam welded pipe, its operation is flexible and the replacement variety is convenient to adjust.

(4) Light weight of equipment, less initial investment. Workers can make it into a trailer-type mobile device and directly produce welded pipes at the construction site where pipes are laid.

(5) Easy to realize mechanization and automation.

The disadvantage of spiral welded steel pipe: it is not easy to align the welding torch, which affects the welding quality. To do this, workers often need to set up complex weld tracking and quality inspection equipment.

Production Process of Spiral Welded Steel Pipe

1.Strictly inspect raw materials;

2.Use single wire or double wire submerged arc welding to butt the end of the strip steel;

3. Strip steel forming before the need for leveling, trimming, surface cleaning and other treatment;

4. Control pressure and smooth transmission;

5. External control or internal control molding;

6. Strictly control data such as pipe diameter and wrong variables;

7. Obtain stable welding specifications;

8. Not only eliminate product defects, but also adjust the process parameters at any time;

9. Use air plasma cutting machine to cut the steel pipe into a single piece;

10. After ensuring that the pipe process is qualified, it is officially put into production

Range of Supply

Taking 60-inch SSAW Steel Pipe as an example, IBC Group will provide customers with the following specifications:

Specification: API 5L/ASTM A53/EN10217/EN10219

Steel Grade: Grade B/X42/X46/X52…S235JRH/S355… and etc.

Outside Diameter: 219.1mm to 3048.0mm (8” to 120”)

Wall Thickness: 6.0mm to 25.0mm

Length: 3M to 40M or customized

Contact with us today!