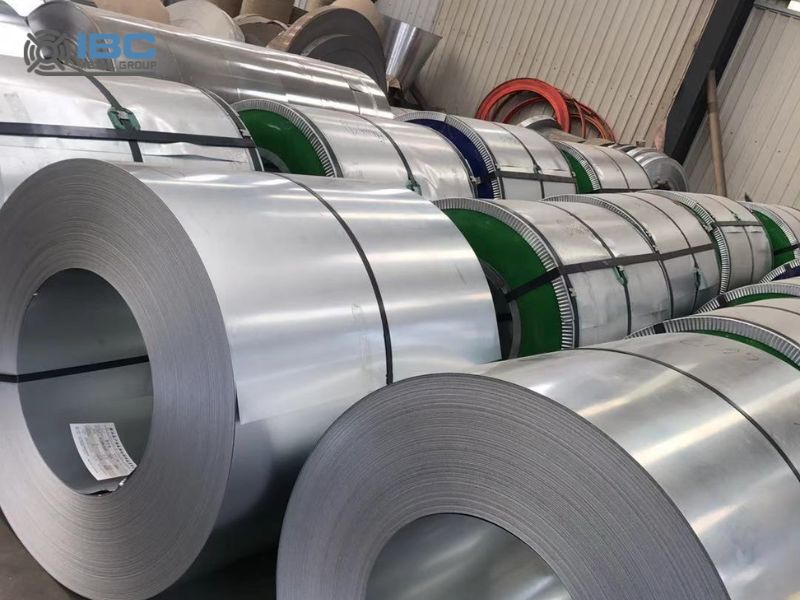

Aluminized zinc coil is a special plate product. It is made of zinc as the substrate and aluminum as the surface coating by cold rolling or hot rolling treatment on the zinc surface.

This plate combines the advantages of aluminum and zinc, and has an alloy structure of aluminum zinc alloy and pig iron matrix. So it has excellent corrosion resistance, high temperature resistance and decorative properties. These characteristics make it widely used in construction, home appliances, transportation and other fields.

Manufacturing Process

1. Development and welding: disassemble the steel plate to expose the strip that needs continuous operation. And then weld the tail of the former strip with the head of the latter strip to ensure the continuity of the production process.

2. Oil removal and cleaning: clean the strip surface to remove impurities such as rolling oil to obtain good coating adhesion and surface quality. This usually involves spraying, brushing, electrolytic cleaning, hot air drying and other processes.

3. Annealing: recrystallization annealing of aluminized zinc steel plate to improve the mechanical properties of the product.

4. Air knife zinc layer control: By spraying liquid (such as air or pure nitrogen) on the strip surface after the steel plate, the coating thickness of the strip surface is controlled to ensure product quality.

5. Particle strengthening treatment: the strip steel is heated to obtain alloy coating and further improve the performance of the plate.

6. Leveling and stretching: small rolling of strip steel, remove the compromise platform of high carbon steel, improve the characteristics of strip steel, improve the stiffness and straightness of strip steel.

7. Post-treatment: Passivation or other chemical surface treatment of steel coils to meet specific corrosion resistance, lubrication or other customer requirements.

Characteristics Of Aluminized Zinc Coil

1. Corrosion resistance: It shows excellent corrosion resistance. This is mainly due to the barrier layer maintenance function of aluminum and the dedicated maintenance function of zinc. In a variety of atmospheric environments, the corrosion resistance of aluminized zinc materials is stronger than that of galvanized sheet, and its normal service life can reach 25 years, which is 3 to 6 times longer than galvanized sheet.

2. Heat resistance: It has a high thermal reflectivity and is very suitable as a roof material. In addition, it also has good heat resistance and can be used in environments up to 315 degrees.

3. Recoating: It has good adhesion with the paint film, and can be directly painted or powdered without special pre-treatment, which makes it perform well in the painting process.

4. Aesthetics: Its surface can be painted with a variety of colors, thereby increasing its aesthetics, while its unique smooth, flat and gorgeous star flower appearance also adds a lot of color.

5. Plasticity: The plasticity of aluminized zinc coil is excellent, which can meet the needs of various complex modeling and bending processing, so that it can flexibly respond to various applications.

6. Simple manufacturing process: compared with other anti-corrosion materials, its manufacturing process is simpler, and its range of use is also wider.

Contact with us today!