Supplier & Exporter of ASTM A875 Aluminized Steel

IBC Metal Group manufactures ASTM A875 Aluminized Steel, which is exported globally. This product consists of steel coil that has been coated in aluminizing with two types of coatings – a Zinc-5% Aluminum-Mixed Metal Alloy (Type I) and a Zinc-5% Aluminum-0.1% Magnesium Alloy (Type II). There are also two classes of coating structures available, with different designations of coating weight [mass]. The hot-dip process applied to the steel sheet in coils and cut lengths also involves small amounts of other elements to improve its processing and characteristics.

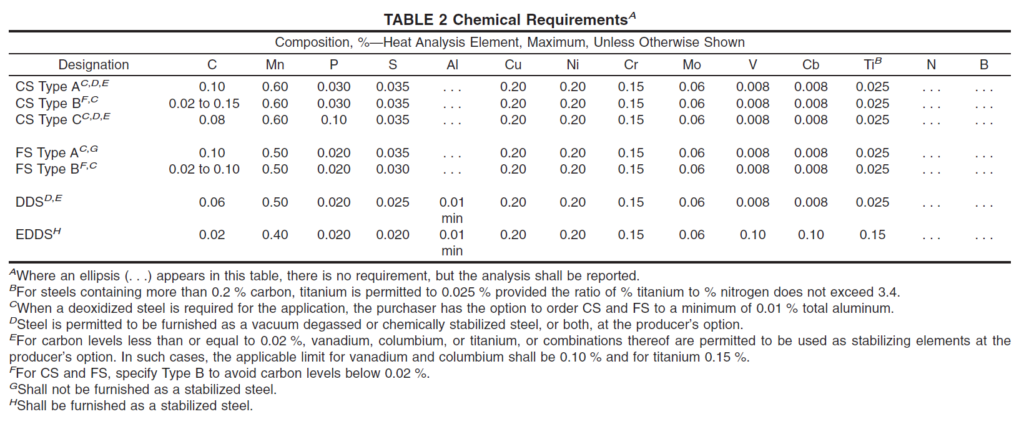

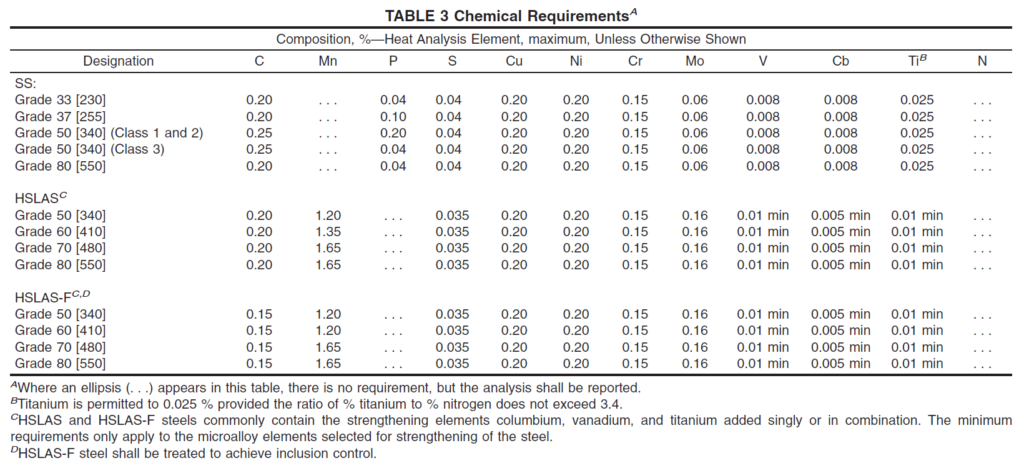

Chemical Composition of ASTM A875 Aluminized Steel

ASTM A875 Base Metal

As shown in Tables 2 and 3, the heat analysis of the base metal must comply with CS (Types A, B, and C), FS (Types A and B), DDS, and EDDS requirements; as well as SS, HSLAS, and HSLAS-F. All the elements included in these tables reported within the heat analysis. Although aluminum corrodes faster than zinc, it still has the benefit of forming a firmly attached oxide layer which protects the base metal. Alongside materials that comply with special specifications, surface post-treatment can boost corrosion resistance further; depending on the application this could be chrome treatment or – in lieu of hexavalent chromization – no treatment at all.

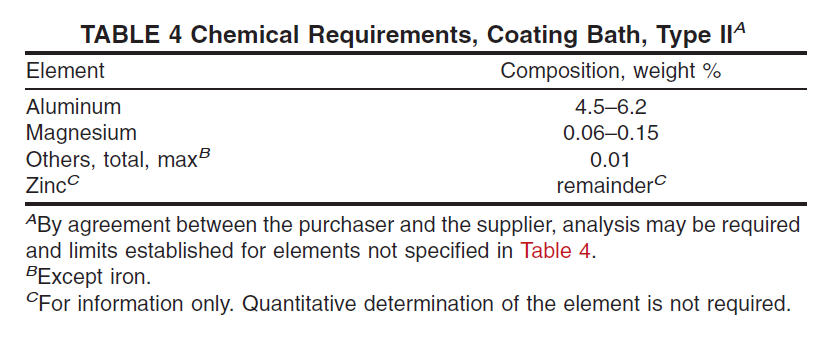

Coating Bath Analysis

Used in continuous hot-dip Zn-5Al-MM alloy coating of the bath metal is Type I. It shall meet the chemical composition limits specified in Specification B750. The bath metal used in the continuous hot-dip Zn- 5Al-Mg alloy coating of Type II. It shall conform to the requirements of Table 4.

Bath Metal – Coating

The chemical composition of a sample can determine via Test Method E47 for tin, ICP argon plasma spectrometric (Test Method E1277), or other methods. In the case of a dispute, the results secured by Test Method E1277 shall use as the basis for acceptance. Additionally, the International Lead Zinc Research Organization has established Practice GF-1 for X-ray fluorescence spectrometry to determine cerium and lanthanum in a zinc–5 % aluminum–mischmetal mix. In any eventuality where there is a conflict regarding results, Test Method E1277 shall again considered the authoritative source.

Mechanical Properties of ASTM A875 Aluminized Steel

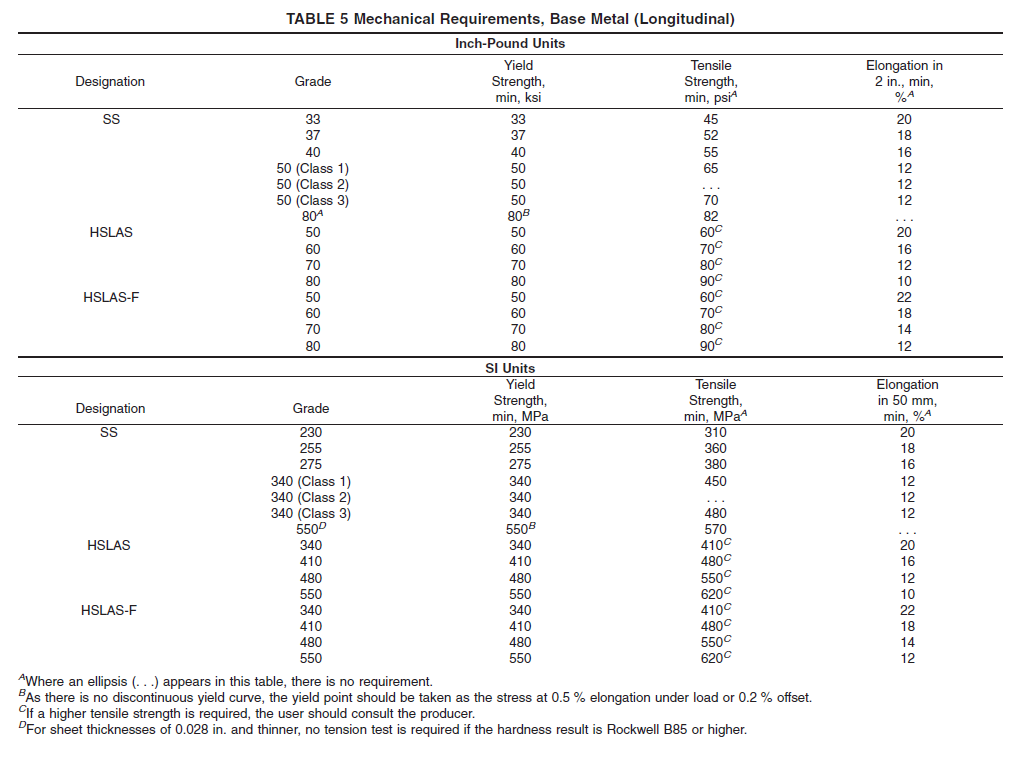

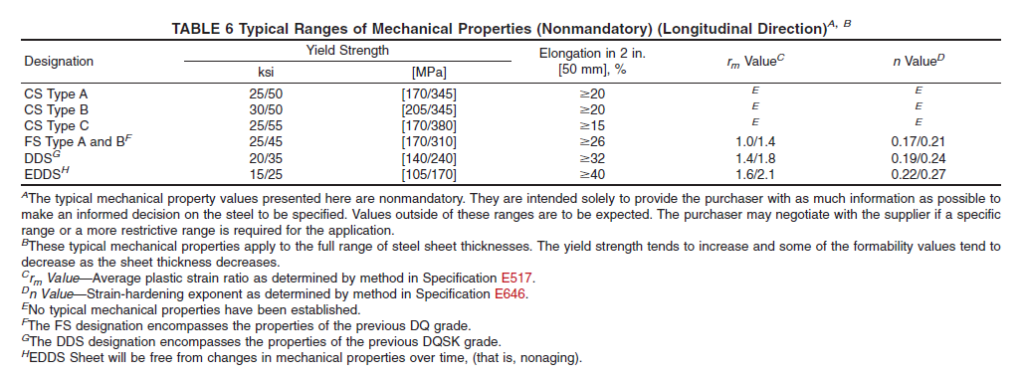

Structural steel, high-strength low-alloy (HSLA) steels and those with improved formability must comply with the mechanical property requirements presented in Table 5. Table 6 contains typical mechanical properties for Cold (Types A, B and C), Formed (Types A and B), Dual Phase and Extra Deep Drawing Steel. These values offered solely to provide purchasers with more information when selecting their steel, as values outside of these ranges are to be anticipated. Mechanical property demands for base metal must test accordingly to Specification A924/A924M.

Bending Properties

Minimum Cold-Bending — Such as Structural steel and high-strength, low-alloy steel, low-alloy sheet steels commonly fabricated by cold bending. There are many interrelated factors that affect the ability of a steel to cold form over a given radius under shop conditions. As these factors include: thickness, strength level, degree of restraint, relationship to rolling direction, chemistry, and microstructure. Appendix X1 lists the suggested minimum inside radius for 90° cold bending for structural steel and high-strength, low-alloy steel. They presuppose “hard way” bending (bend axis parallel to rolling direction) and reasonably good shop forming practices. Where possible, the use of larger radii or “easy way” bends recommended for improved performance. Fabricators should be aware that cracks may initiate upon bending a sheared edge. This is not considered to be a fault of the steel but is rather a function of the induced cold-work.

Coating Properties of ASTM A875 Aluminized Steel

Weight of Coating [Mass]

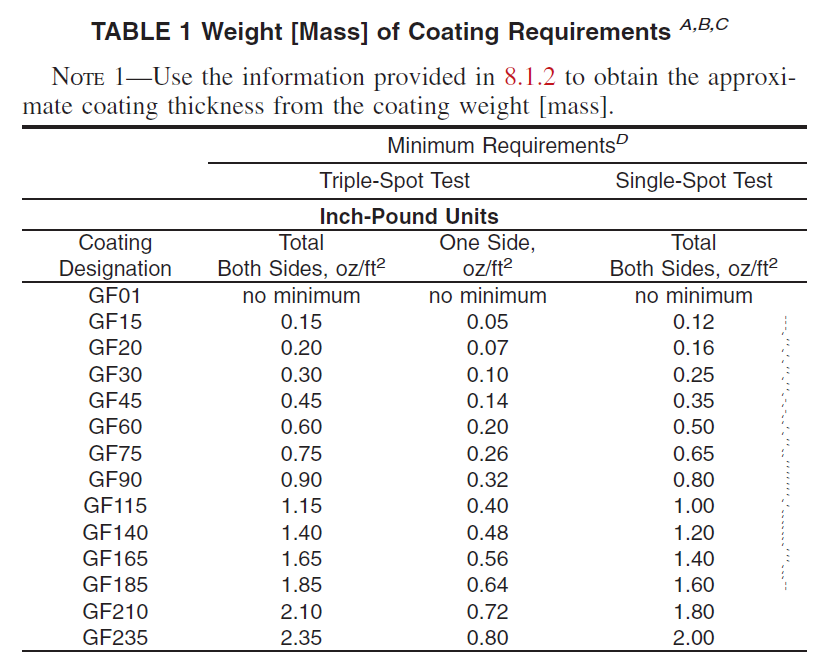

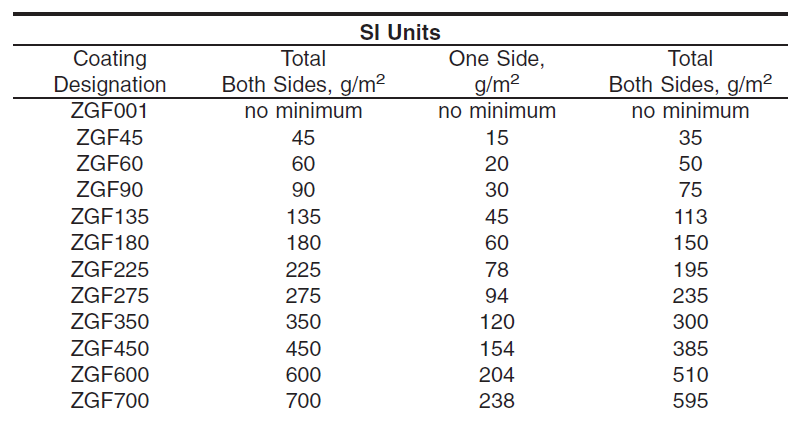

As shown in Table 1, coating weight [mass] shall conform to the requirements for the specific coating designation. Use the following relationships to estimate the coating thickness from the coating weight [mass] – 1.00 oz/ft2 coating weight =1.75 mils coating thickness, and 6.83 g/m2 coating weight = 1.00 μm coating thickness. Use the following relationship to convert coating weight to coating mass: 1 oz/ft2 coating weight =305 g/m2 coating mass.

Tests of Coating Weight [Mass]

Coating weight [mass] tests shall be performed in accordance with the requirements stated in Specification A924/A924M. The referee method to use shall be Test Method A90/A90M.

Coating Bend Test

The bend test specimens of coated sheet designated by the prefix GF [ZGF]. It shall be capable of bent through 180° in any direction without flaking of the coating on the outside of the bend only. The coating bend test inside diameter shall have a relation to the thickness of the specimen as shown in Table 7. Flaking of the coating within 0.25 in. [6 mm] of the edge of the bend specimen shall not be cause for rejection

Conclusion

IBC (Tianjin) Industrial Co., Ltd exports a wide range of steel items, like coil and sheets, pipes, fittings, and specialized steel. Whatever is your requirement for steel products in your projects, we have the capacity to supply them all. These steel sheets produced in different configurations to meet diverse usage conditions whilst delivering corrosion resistance, decent formability and paintability.

Contact with IBC Metal Group