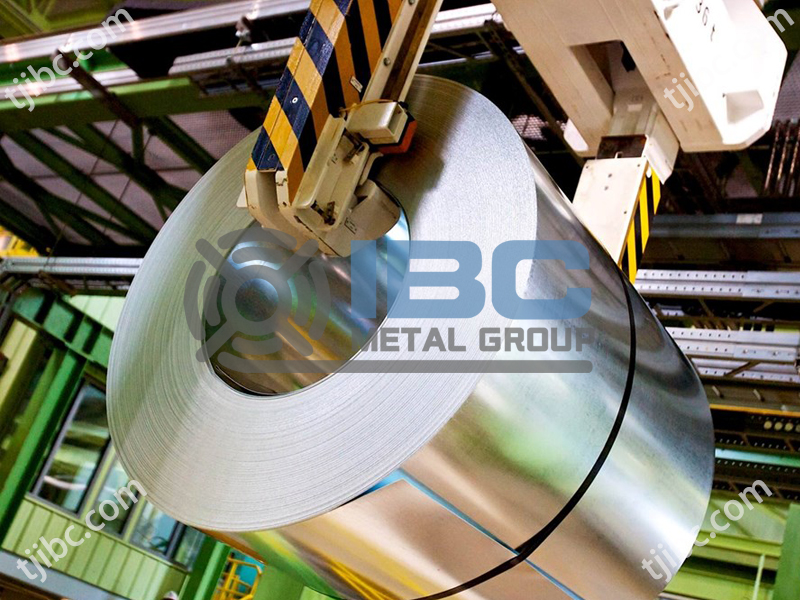

DIN EN10346 Aluminized Steel Manufacturer

IBC Metal Group manufacturer DIN En10346 Aluminized Steel for decades years. The specification EN10346 full name is Continuously Hot-Dip Coated Steel Flat Products For Cold Forming-Technical Delivery Conditions.

This European Standard sets out requirements for continuously hot-dip coated products made of a range of low carbon steels, steels intended for construction, and high proof strength steels suitable for cold forming. Coatings consist of zinc (Z), zinc-iron alloy (ZF), zinc-aluminium alloy (ZA), aluminium-zinc alloy (AZ), aluminium-silicon alloy (AS) or zinc-magnesium alloy (ZM) and the thicknesses lie between 0.20mm and 3.0mm for multiphase steels for cold forming with coatings of zinc(Z), zinc-iron alloy (ZF), zinc-aluminium alloy (ZA) or zinc-magnesium alloy (ZM).

Specifications & Features & Advantages

Specifications & Features

- Type of zinc coating finish: regular spangle, minimized spangle and skin-pass.

- Types of surface qualities: as coated surface, improved surface and best quality surface.

- Surface treatment: chemically passivated, chromate-free passivation, phosphate, anti-finger print, phosphate and, self lubricating film, and untreated.

- Types of oiling: oiled and unoiled.

- Coil ID: 508/610mm.

- Grade: HX160YD / HX180 / BD / HX300LAD;

Advantages

- To ensure a smooth, high-quality finished product, IBC’s hot-dip galvanized steel sheets manufactured using techniques perfected over many years of experience, on a line that is continuously galvanizing. We at IBC Metal Group committed to providing a wide range of base metal qualities for galvanized steel sheet, including commercial, lock forming, drawing, and structural quality. Each product undergoes a chromatic process to prevent rust.

- IBC Metal’s cold rolling facility produces galvanized steel sheets that are highly workable and highly workable. During the annealing, galvanization, and leveling of coils, the base metals continuously annealed, galvanized, and leveled to ensure superior formability.

- Furthermore, galvanized steel sheets treated with chromic acid to prevent rusting and maintain their original luster. Thanks to a rigorous quality control process and a quality inspection based on high quality standards, product quality, dimensions, and other properties are strictly matched to customer requirements.

What is the Application of Aluminized Steel Coil?

There are two sides. The one is outside: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth. The other is inside: door, door-case, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Buildings and constructions. Floor decks, ceilings, duct work, roofing, siding, sashes, beams, fences, verandas, shutters, awnings, partitions, indoor decorations, pipes, ventilators, sheds, culverts.

- Transportation. Body pane, air cleaners, oil filters, fuel tanks, containers, highway barriers.

- Appliances. Light fittings, washing machines, dryers, coolers, vending machines, water heaters, stoves, refrigerators, freezers, tool boxes.

- Agriculture barns. Dryer panels, animal houses, hoppers, bar supporters, irrigation systems, green houses.

- Others. Furniture and office equipment, entertainment machines, car ports, garden and storage sheds

Meaning of Different Coatings

N – Zinc Coating Finish–Common Zinc Crystal

Due to this design, the zinc coating solidifies unaffected. According to the galvanizing conditions, either zinc crystals with different gloss and size may be present, or no zinc crystals may be present.

M – Zinc Coating Finish–Small Zinc Crystal

This design results by deliberately influencing the solidification process. It has a smaller zinc flower, which may not be visible to the naked eye in some cases. This design used when the usual zinc flower fails to meet the requirements of the surface’s appearance.

ZF – Coating Design for Zinc-Iron Alloy

The coating of a zinc-iron alloy in a usual condition formed by a heat treatment in which iron diffuses through the zinc. The surface has a uniform matt gray look.

ZA – Coating Design for Zinc-Aluminum Coatings

An unaffected solidification of the zinc-aluminum coating results in this version with a metallic luster. Depending on the manufacturing conditions, crystals of different gloss and of different sizes formed. The quality of the coating not affected.

ZM – Coating Design for Zinc-Magnesium Coatings

Resulting from an unaffected solidification of the zinc-magnesium coating, this version has a metallic sheen, possible images, and a tendency to darken.

AZ – Coating Design for Aluminum-Zinc Coatings

The products delivered with standard crystals. Common crystals are a version with metallic luster, which results in unaffected growth of aluminum-zinc crystals under normal solidification conditions.

AS – Coating Design for Aluminum-Silicon Coatings

In contrast to the other hot-dip coated products, a relatively pronounced Al-Fe-Si alloy layer formed on the base material during hot dipping. This taken into account in further processing steps.

Conclusion

IBC (Tianjin) Industrial Co., Ltd is one of leading steel products manufacturer in China. We specialized in supplying all kinds of steel products for your projects. Such as coils and sheets, steel pipes, pipe fittings in different materials. Carbon steel, cast iron, malleable Iron, stainless steel, etc. For more information please contact with us. Our specialist will provide you our best services.

Contact with IBC Metal Group