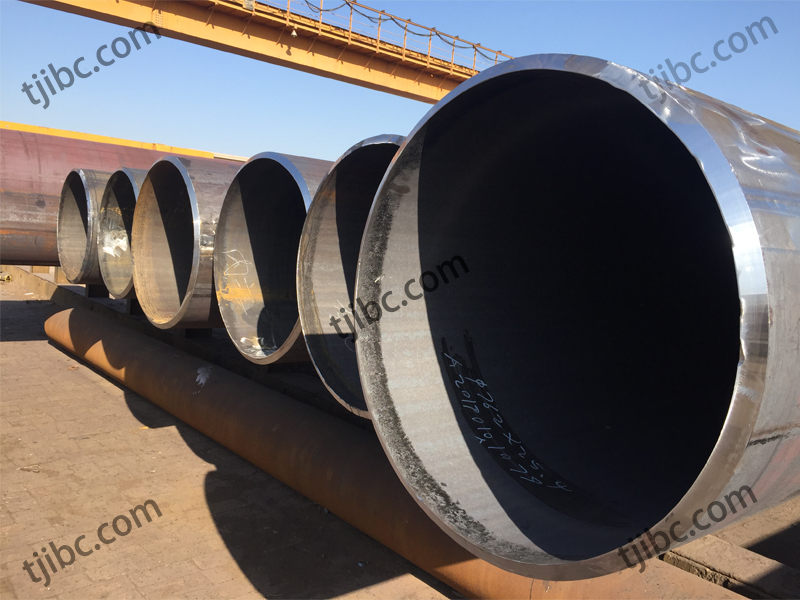

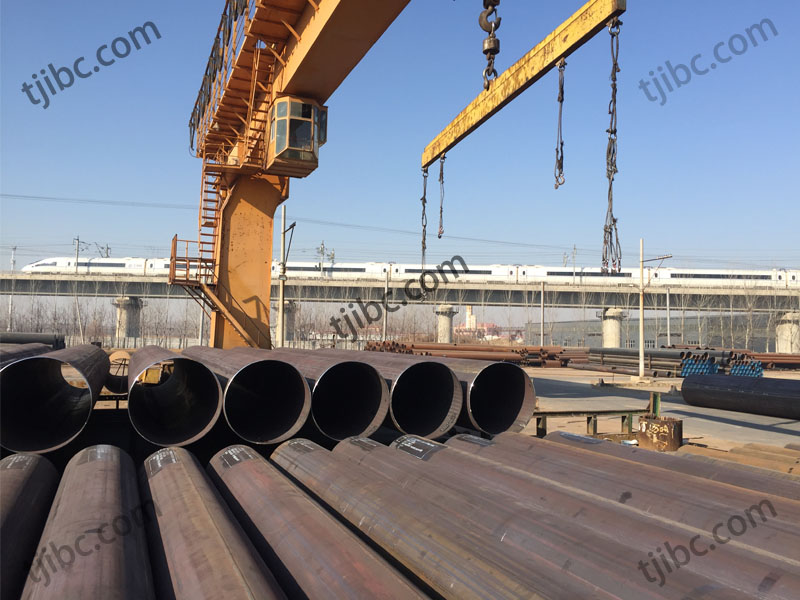

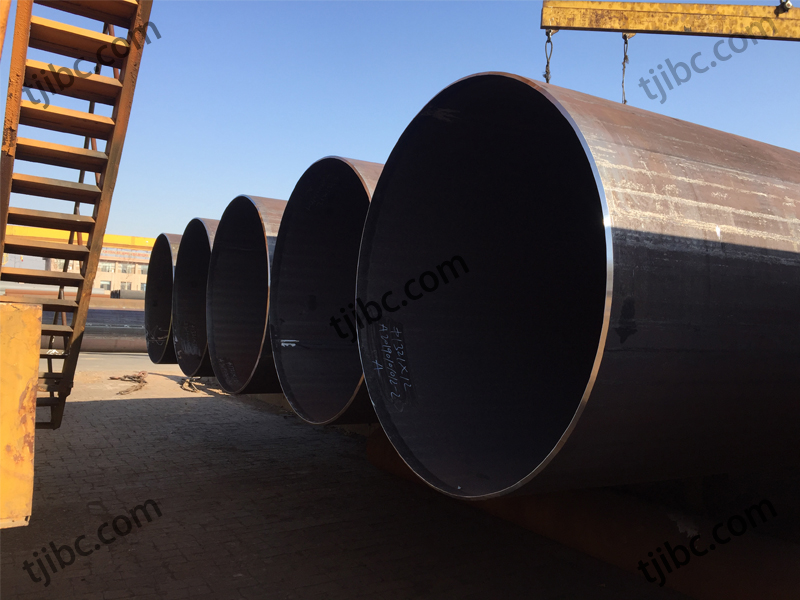

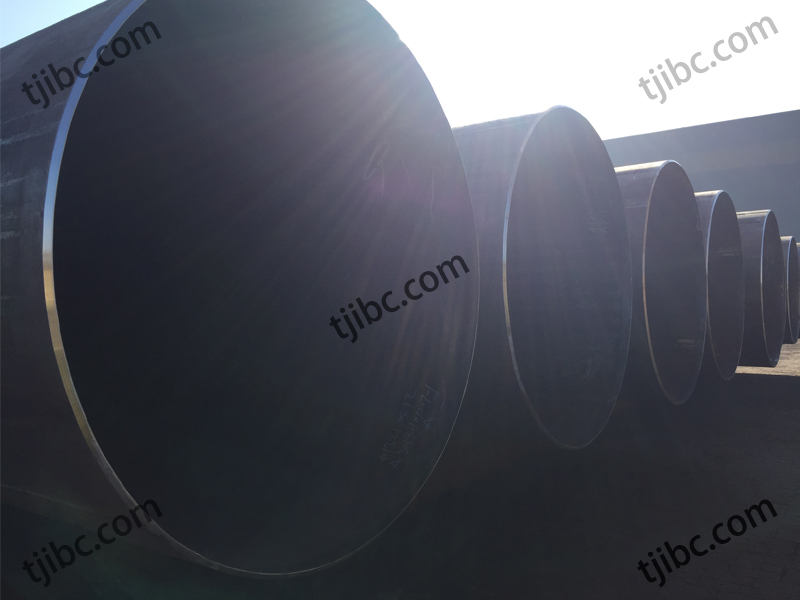

1321mm LSAW Steel Pipe Manufacturer

IBC (Tianjin) Industrial Co.,Ltd produce 1321mm LSAW Steel Pipe for decade years. LSAW (Longitudinal Double Submerged Arc Welding), also called SAWL pipe carbon steel pipe is a type of SAW pipe made of steel plates that were hot rolled by JCOE or UOE forming technology. Usually LSAW steel pipe have one single and straight weld seam. But the O.D. larger than 914.4mm LSAW could prefer two straight welding seams. It can also called dsaw steel pipe. Of course, we could do one welding seam for the sizes above 914.4mm according to your requires.

LSAW Pipes are made from steel plates, molded using a molding machine, and then submerged arc welding. Through this process, the LSAW steel pipe has excellent ductility, weld toughness, uniformity, plasticity, and great sealing. Compared to UOE vs JCOE pipes, LSAW steel pipe manufacturers in China can produce more sizes, such as:

Supply Range of LSAW Pipe

- Standard Specification: API 5L / A671 / A672 / En10219 / ASTM A252

- Outside Diameter (O.D.): 406.4mm ~ 1524mm

- Wall Thickness: 5.0mm ~ 40mm or more

- Length: 3M ~ 12.5M

- Pipe End: Beveled End, Plain end, Grooved end, or customized according to your requirements.

- Coating: Fusion Bond Epoxy Coating; 2PP, 2LPE, 3PP, 3LPE, Black Vanished, Coal Tar Epoxy; Bitumen Coating; Black Oil Coating as Per Customer’s requirement.

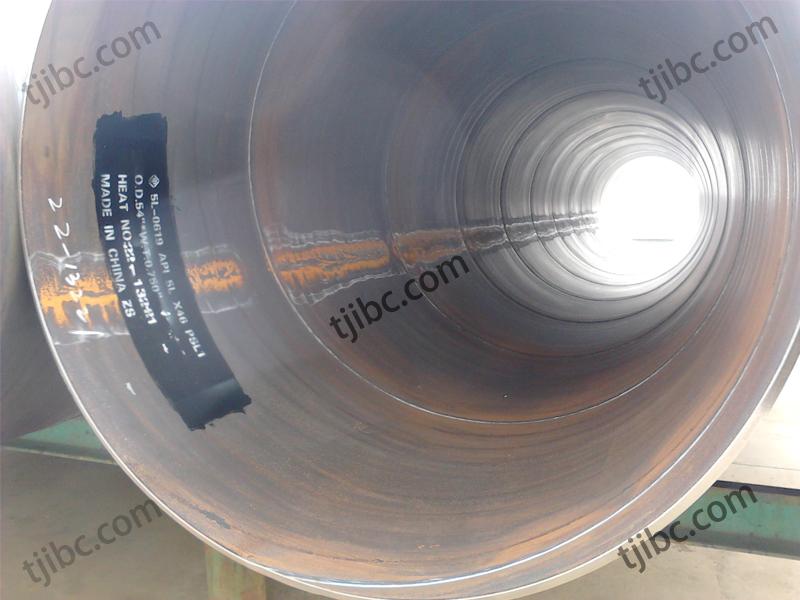

Description of 1321mm LSAW Steel Pipe

- Specification: API 5L

- Steel Grade: Grade B

- Outside Diameter: 1321mm LSAW Steel Pipe

- Wall Thickness: 12mm

- Length: 11.98M

Other Steel Grade of LSAW Pipe

Grade A; GrB; X42; X46; X52; X56; X60; X65; X70; X80 and etc. CL10 ~ CL13; CA55; B65; B70; C70; S275JRH; S275J0H; S275J2H; S355JRH; S355J0H; S355J2H; Gr.2/Gr.3. and other steel grade.

Tests for Pipes

All LSAW steel pipe should take kinds of tests and inspections before it finished. Such as Chemical Component Analysis; Mechanical properties including elongation, yield strength, ultimate tensile strength; Technical properties (DWT test, Impact test, Blow test, Flattening test); X-ray test; Exterior size inspection; Hydrostatic test, UT test, etc. And before loading on the ship, we also accept the 3-party Inspections. Any questions, please contact with us.

How to Use LSAW Pipe for Pipelines

In accordance with the API 5L Spec, we perform tests on primary metal as well as welding metal. In addition to this, other specifications such as DIN, EN, ASTM and GOST are also applicable. Moreover, the LSAW steel pipe can be connected by means of flanges. As per customer needs, welding eye hooks or any other part can be done. Apart from serving as a pipe boot or pile boot (as a safeguard for sections), the LSAW steel pipe is also transported across in liquids like water, oil & gas; and thus used in offshore projects and underground constructions. All these products are sourced from China which are further exported to countries including Australia, Canada and South America, Europe, Malaysia, India, Pakistan, Africa etc.

Conclusion

The LSAW steel pipe is widely used in various pipeline engineering and construction due to its high reliability and safety performance, and it can also be used in engineering in the chemical industry, electric power, irrigation, construction, and piling. LSAW steel pipes are manufactured and exported by IBC Metal Group. Due to our large supply range, we are popular all over the world. 1321mm LSAW steel pipe is a common size used for offshore projects. You can also contact us if you need more information, such as 600mm LSAW pipe, or other specified dimensions.

- E-mail: [email protected]

- Tel: +86-22-27168866

- [email protected]

Contact With IBC Group

C