When we talk about the differences between LSAW pipe and SSAW pipe, we could see it from its name. LSAW pipe and SSAW pipe are all submerged arc welded type pipes. LSAW, short for longitudinally arc welded steel pipes. And the weld seam is longitudinal or simply say it straight seam. And SSAW, short for Spiral Submerged Arc Weled pipe. The weld seam is spiral. So the main different is the type of weld seam. All these two pipe are large diameter pipes. And they have differences in many other ways. Such as manufacturing process, diameter range, and performance, even the applications are different. IBC (Tianjin) Industrial Co.,Ltd could supply both LSAW and SSAW pipe in all sizes.

Firstly, Different in Manufacturer Process

SSAW pipes welded in the helix or spiral position while LSAW pipes welded in the longitudinal direction. SSAW pipe takes form by rolling and welding a steel strip in a way that the pivotal direction is oblique to the axis or pipe center, making the weld seam in a spiral line.

Manufacturing Process of LSAW Pipe

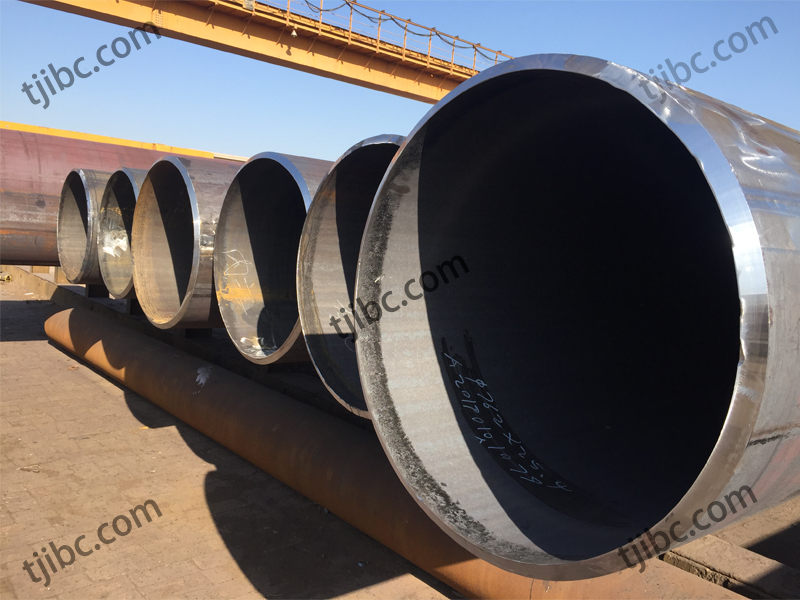

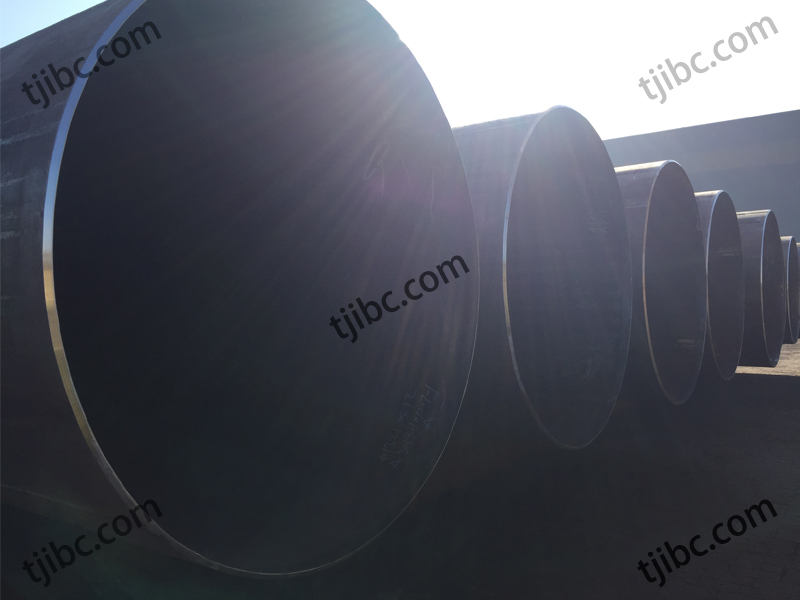

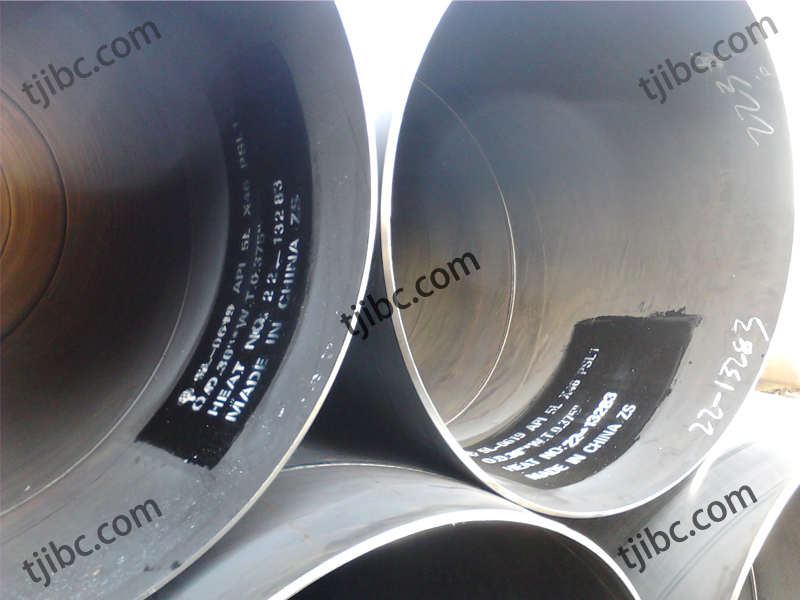

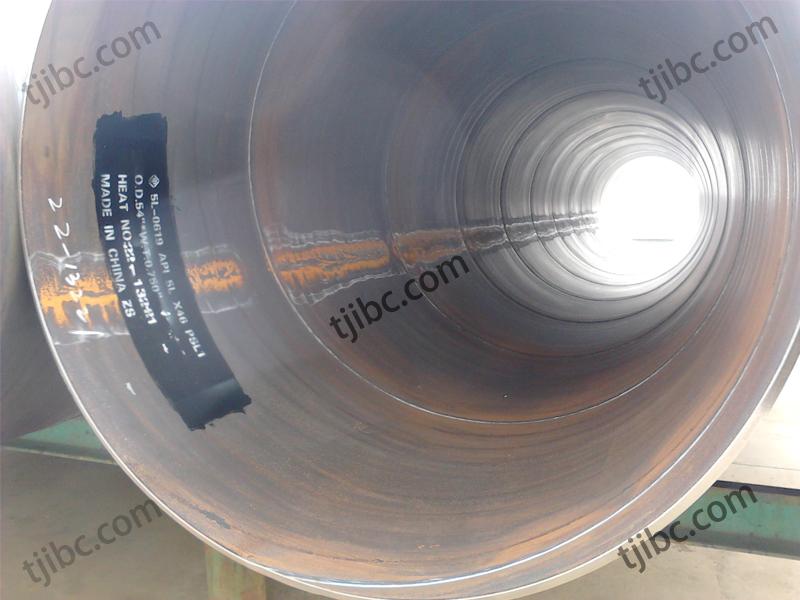

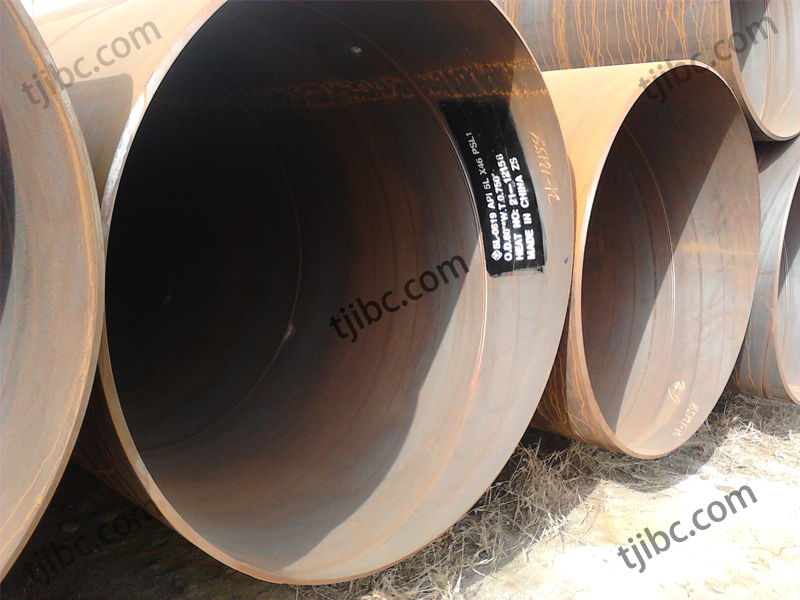

It is short for Longitudinal Submerged Arc-Welding. We also called SAWL pipe. It is taking the steel plate as raw material, mold it by the molding machine, then do double-sided submerged arc welding. Through this process the LSAW steel pipe will get excellent ductility, weld toughness, uniformity, plasticity and great sealing. It could have one welding seam or two welding seams. It is according to the outside diameter and your requirements. Such as diameter upper than 914.4mm, it could prefer to using two welding seams.

Manufacturer Process of LSAW Pipe

Manufacturing Process of SSAW Pipe

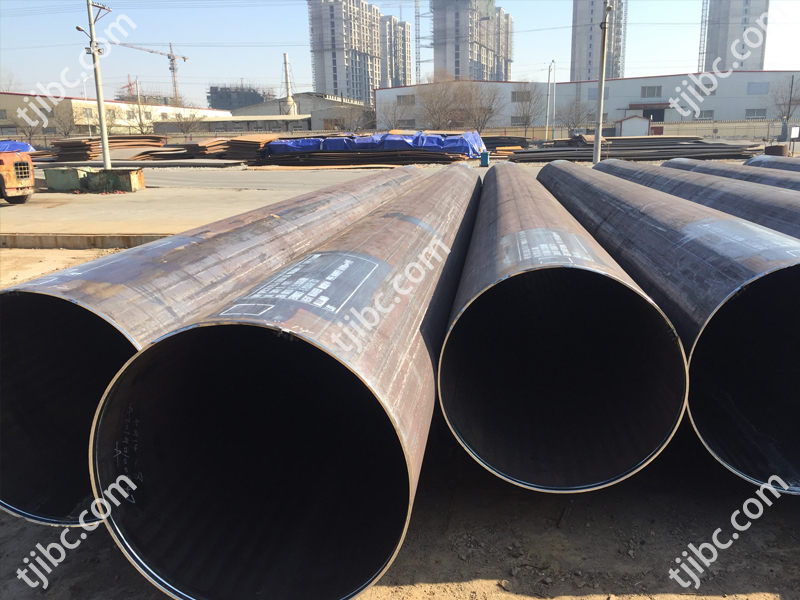

SSAW Pipe short for Spiral Submerged Arc-Welding Pipe. We also called HSAW pipe (Helical SAW), welding line shape like a helix. It is using the same welding technology of Submerged Arc-Welding with LSAW pipe. Differently SSAW pipe is spiral welded where the LSAW is longitudinally welded. Manufacturing process is rolling the steel strip, to make the rolling direction have an angle with the direction of the pipe center, forming and welding, so the welding seam is in a spiral line.

Manufacturing Process of SSAW Pipe

LSAW and SSAW employ the same manufacturing technology – JCOE process. SSAW pipes welded in the helix or spiral position while LSAW pipes welded in the longitudinal direction. Manufacturing process of SSAW pipe is by rolling and welding a steel strip in a way that the pivotal direction is oblique to the axis or pipe center, making the weld seam in a spiral line.

Secondly, Different Diameters Range of LSAW and SSAW Pipe

Range of LSAW Pipe

The LSAW pipe diameter range is larger than ERW, normally from 16 inch to 60 inch, 406mm to 1500mm. Good performances on high pressure resistance, and low-temperature corrosion resistance. And length could range from 1.0M to 12.5M. And it has restriction on length. If you want the length longer, it must be but welded.

SSAW Pipe (HSAW Pipe) Size Range

The SSAW pipe diameter range is from 8 inch to 120 inch, 219.1 mm to 3048 mm. And its length do not have limitation. It could reach 33M.

It will depending on the transportation method. The advantage part is we can get the different diameter of SSAW pipes with the same size of the steel strip, there is a wide application for the raw material steel strip, and welding seam should avoid the primary stress, good performances to bear the stress. The disadvantage is the bad physical dimension, welding seam length is longer than the pipe length, easy to cause the defects of cracks, air hole, cinder inclusion, partial welding, welding force in pulling status.

Thirldy, Different Applications of LSAW Pipe and SSAW Pipe

Applications of LSAW pipe

It has been widely applied in the oil and gas pipelines, specially required large diameter and thick wall pipe with high strength and long distance. Meanwhile in construction of structure that need tough strength, water treatment, thermal industry, bridge building, etc. According API specifications, the LSAW pipe (SAWL pipe or JCOE pipe) is specially designated in large scaled oil and gas transportation, in the cases that pipelines across the city, sea, and the urban area. These are the class 1 and class 2 areas.

Applications of SSAW pipe

For oil and gas pipeline systems, but in petroleum design specification, the SSAW pipe / HSAW pipe could only be applied in class 3 and class 4 areas. Construction structure, water transport and sewage treatment, thermal industry, buildings etc.

LSAW Pipe Has Better Performances Than SSAW Pipe.

As above the specs of the both kind SAW pipe, it defined that SSAW pipe will be used in the area that not very important. SSAW pipes has greater residual stress than LSAW pipes. LSAW pipes passes through uniform expansion process.

SSAW pipes weld stress concentration phenomenon is serious. The heat affected zone of SSAW pipes is larger than LSAW pipes. Heat affected zones are considered weak points where failure might start. Geometry accuracy of LSAW pipes is better than SSAW pipes, a key in the ease of installation. The welding line of LSAW pipe is around 60% lesser than of SSAW pipes. Using steel plates, quality of LSAW pipe can be tested by non-destructive procedures. While SSAW pipes using hot-rolled coils should be tested with destructive methods such as x-ray. LSAW pipes adopt welding after molding process where various checks can take place. SSAW pipes employ molding and welding at the same time, pre-checks are not being carried out.

Until now, United States, Japan, Germany have reject attitude for SSAW pipe, and not suggested in the key pipelines. Canada and Italy use SSAW pipe for partial pipelines. Russian few pipelines in SSAW, plus they have made strict implement terms. And for China, because of the historical factors, most of the key pipelines in China still use SSAW pipe.

Compared to seamless pipe, ERW pipe and SAW pipe is mainly used in oil and gas transportation. Where Seamless steel pipe is mainly used in oil and gas drilling, explorations.

IBC Metal Group could supply & export all kinds of pipe. Such as LSAW pipe, SSAW pipe, ERW pipe, Seamless pipe, Galvanized pipe, Rectangular pipes, Stainless stele pipe, Aluminized pipes, and so on. Together with pipe fittings as well. And we also have steel plate, steel coils, and other related steel products hard to find in the market. We could find all of the for you and suitable for your projects.

Contact with us today!