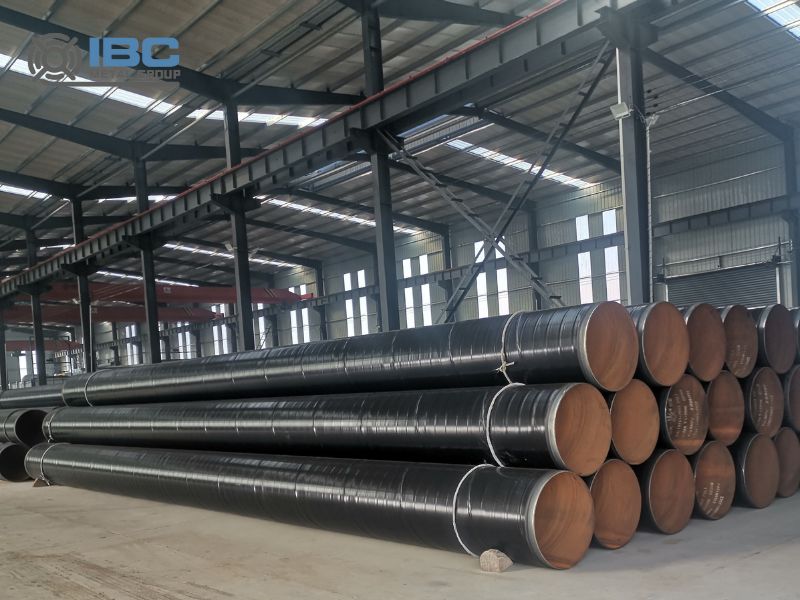

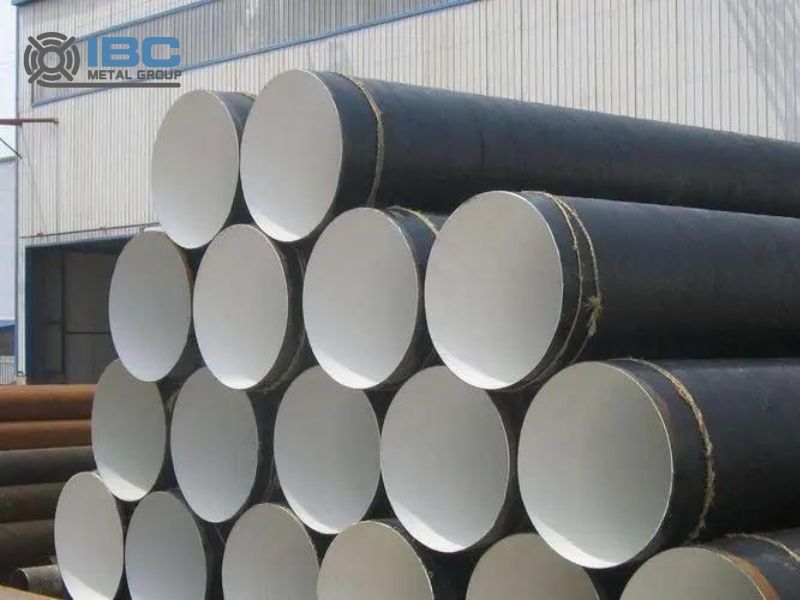

3PE anti-corrosion steel pipe, the full name is 3-Layer Polyethylene (3-layer Polyethylene) anticorrosive steel pipe. It forms a complete anti-corrosion barrier by coating primer, copolymer bond layer and medium and high density polyethylene three layers on the surface of the steel pipe in turn.

This anti-corrosion technology combines the advantages of epoxy powder coating and polyethylene coating for a longer service life and greater anti-corrosion ability.

Production Process 1

1. Steel pipe surface treatment: The purpose of this step is to remove oil, rust and other impurities on the surface of the steel pipe to ensure that the subsequent coating can be evenly and closely attached to the surface of the steel pipe. The treatment method usually includes mechanical cleaning and chemical cleaning to ensure that the cleanliness and roughness of the steel pipe surface meet the requirements.

2. Primer: The main function of primer is to enhance the binding force between the surface of the steel pipe and the subsequent 3PE coating to prevent the coating from falling off. The choice of primer takes into account its corrosion resistance, adhesion and compatibility with other coatings.

3. Heat treatment: The purpose is to make the primer better penetrate into the small gaps and depressions on the surface of the steel pipe, so as to enhance the binding force of the coating and the steel pipe.

Production Process 2

4. Coating production: 3PE coating is composed of three layers: fused epoxy powder layer, adhesive layer and polyethylene layer. These three layers of materials are successively coated on the surface of the steel pipe under specific process conditions to form a strong, corrosion-resistant protective layer.

5. Coating drying: The purpose is to make the moisture and solvent in the coating volatile, so that the coating curing. The drying temperature and time need to be determined according to the material and thickness of the coating to ensure that the coating can be fully cured.

6. Steel pipe cooling: The purpose of cooling is to bring the steel pipe and coating to room temperature. This prevents the coating from deforming or cracking during subsequent processing and use.

7. Quality inspection: The content of the quality inspection includes the thickness, uniformity, adhesion of the coating and the geometry of the steel pipe.

Performance of 3PE Anti-Corrosion Steel Pipe

1. Excellent corrosion resistance: The design of the three-layer structure makes it have excellent corrosion resistance and can resist the erosion of chemical substances in soil, water and other media.

2. Good mechanical properties: the coating has good elasticity and wear resistance, and can resist external mechanical damage and impact.

3. Convenient construction: 3PE anti-corrosive steel pipe adopts hot melt connection or electric melt connection, easy and fast connection, and good sealing performance.

4. Environmental protection: The materials used are non-toxic and harmless, meeting the requirements of environmental protection.

5. Economy: Compared with traditional anticorrosion methods, it has a longer service life and lower maintenance costs.

Future Development Trend and Application

Global energy and infrastructure development is constantly advancing. This pipeline will continue to be widely used in the future as an efficient and economical anti-corrosion solution. At the same time, with the development of technology and the improvement of environmental protection requirements, its materials and technology will continue to innovate and upgrade. In this way, higher performance requirements and environmental standards can be met.

1. Oil and natural gas transportation: It can effectively prevent the corrosion of the medium to the pipeline. And it can also ensure the safety of transportation.

2. Urban water supply and drainage: 3PE anti-corrosion steel pipe has a wide range of applications in urban water supply and drainage systems. It can ensure the stability of water quality and long-term operation of pipelines.

3. Chemical, pharmaceutical industry: This steel pipe can withstand the erosion of various chemical substances. This can ensure the smooth progress of the production process.

4. Agricultural irrigation: Agricultural irrigation. It can resist soil and water erosion and ensure the long-term stable operation of the irrigation system.

Contact with us today!