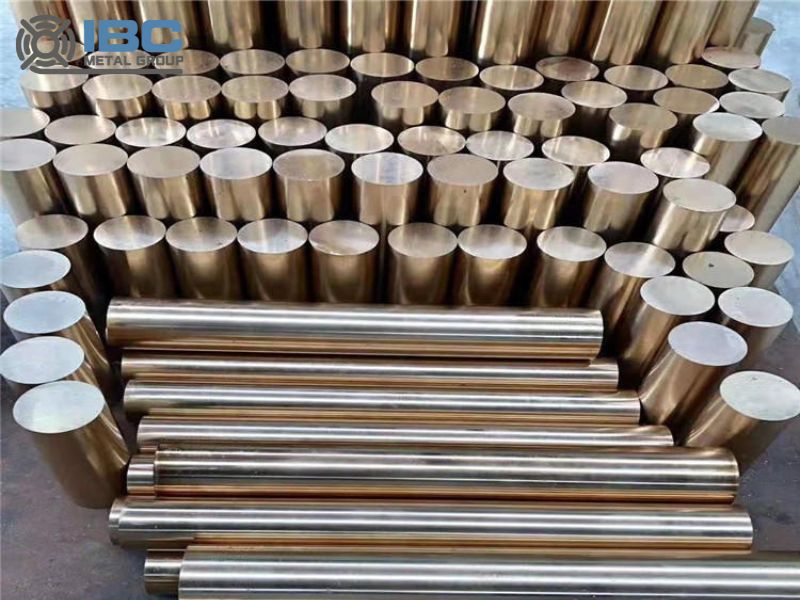

Beryllium copper (beryllium bronze) is currently a representative alloy for high-end manufacturing industries such as electronics, new energy vehicles, communications, and aerospace. And it is also an important basic material for national economic construction and high-tech development. Please consult IBC Group for specific material selection

Material Characteristics

The alloy can be strengthened by heat treatment. It is an ideal high-conductivity and high-strength elastic material, and is the “king of elasticity” in copper alloys.

Beryllium copper is non-magnetic, anti-spark, anti-wear, anti-corrosion, anti-fatigue and anti-stress relaxation, while combining strength, electrical conductivity and workability. And it is easy to cast and pressure process forming. It is widely used in connectors, switches, relays and other electronic components.

Features

(1)With high strength, high elasticity, high conductivity, high temperature resistance, fatigue resistance, corrosion resistance and other characteristics.

(2)In the case of high strength, high elasticity and other characteristics, it also has excellent electrical conductivity

(3)Because of its high reliability, heat resistance and high conductivity. It is widely used in various parts of new energy vehicles.

(4)It is the best material for applications in the fields of electronics, communications and Marine engineering. It has excellent corrosion resistance in seawater, no change in strength and elongation after corrosion. And it can maintain a life of more than 40 years in seawater. It is an irreplaceable material for the submarine cable repeater structure.

Application of Beryllium Copper

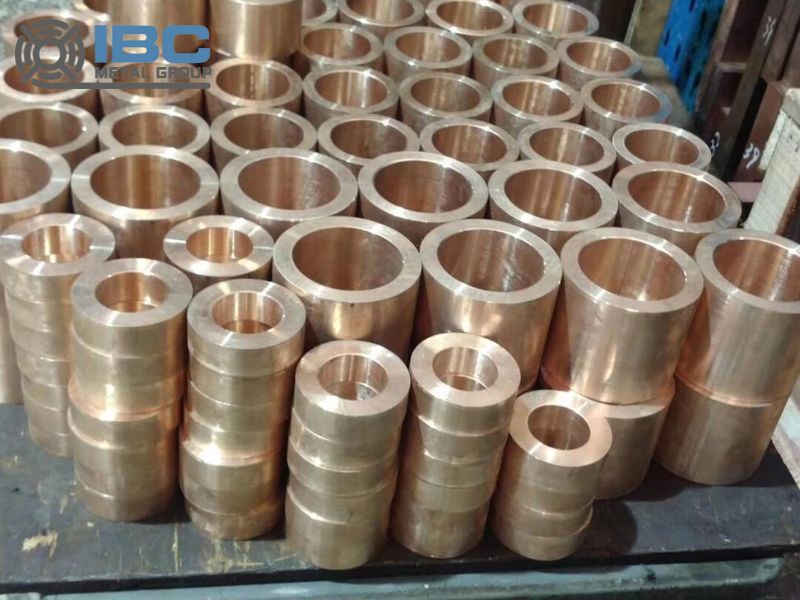

(1) Used as conductive elastic element and elastic sensitive element. More than 60% of the total production of beryllium bronze is used as an elastic material. For example, in the electronics and instrumentation industry, workers use it to make switches, reeds, contacts, contacts, diaphragms, bellows and other elastic components.

(2) Used as sliding bearings and wear-resistant components. Because of its good wear resistance, factories also use it to make bearings on computers and many civil aircraft. For example, American Airlines used beryllium bronze instead of copper bearings. And the service life was increased from 8000h to 28000h. The power lines of electric locomotives and trams made of beryllium bronze are not only resistant to corrosion, wear, high strength, but also have good electrical conductivity.

(3) Used as a safety explosion-proof tool. In petroleum, chemical, gunpowder and other environmental work, bronze plating can make a variety of operating tools. Various explosion-proof work also has its figure.

(4) The application of plastic molds. Due to the high hardness, strength and good thermal conductivity and castability of beryllium copper alloy, molds with high precision and complex shape can be directly cast, and the finish is good, the pattern is clear, the production cycle is short, and the old mold materials can be reused and the cost can be saved. Workers can use it to make plastic molds, die casting molds, precision casting molds, corrosion molds and so on.

(5) Application of high conductive beryllium copper alloy. For example, Cu-Ni-Be and Co-Cu-Be alloys have very high strength and conductivity, with conductivity up to 50%IACS. The contact electrode of the welding machine and the elastic components with high conductivity in electronic products are also inseparable from it. The application of this alloy is gradually expanding.

Contact with us today!