There are many kinds of metal roofing sheet. It includes but is not limited to galvanized plate, aluminum-plated zinc plate, aluminum alloy plate, aluminum-magnesium alloy plate, titanium alloy plate, copper plate, stainless steel plate, etc. The surface of these plates is usually painted. This enhances its durability and aesthetics. The main ways of paint treatment are PE/PE, SMP/PE, HDP\PE, PVDF\PE and so on. These treatments can significantly extend the life of the sheet.

Advantages

Light weight: Metal roofing sheets are lighter than other building materials. It not only helps reduce the load on the building structure, but also facilitates transportation and installation, thus saving costs.

Strong corrosion resistance: After special processing and treatment, it has strong corrosion resistance. It can resist wind and rain erosion in the natural environment and ensure the service life of the building.

Sound insulation effect is good: the characteristics of metal materials make it have excellent sound insulation and heat insulation performance, providing a good living and working environment for the building.

Good fire performance: In the production process workers will add flame retardants, thereby improving its fire performance. In the event of a fire, the high density of metal sheets and the addition of flame retardants can slow down the burning rate and reduce the production of toxic gases.

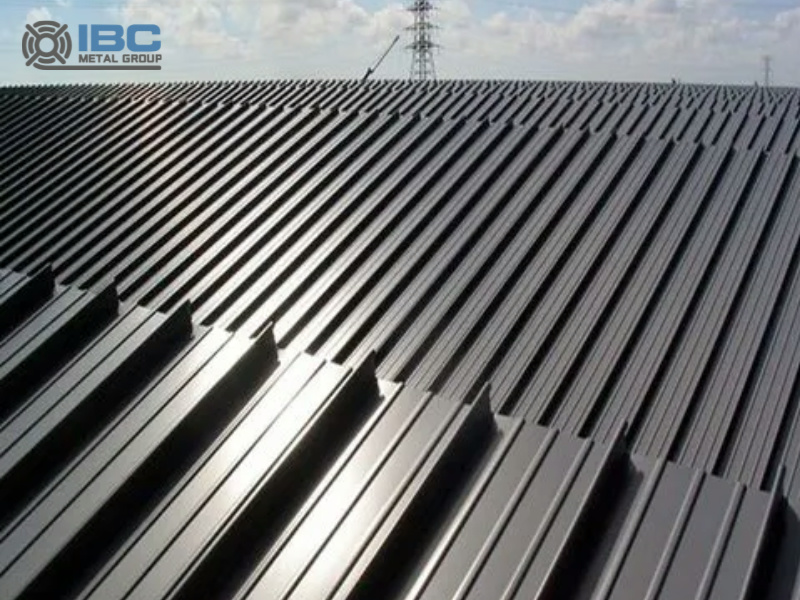

Beautiful and generous: It has a rich choice of colors and textures to meet different architectural styles and aesthetic needs. At the same time, its design without connection and screw hole makes the appearance of the building more complete and beautiful.

The Process of Making Metal Roofing Sheet

Raw material preparation: Select metal raw materials that meet the standard according to the design requirements, such as aluminum ingots, titanium ingots, etc.

Melt casting: The metal raw material is melted into a liquid state by an electric furnace.

Molding process: The use of die casting machine or extruder and other equipment to die cast or extrude liquid metal into the shape of the sheet.

Surface treatment: The surface cleaning, grinding and spraying primer of the molded sheet are processed to enhance its corrosion resistance and beauty.

Cutting processing: According to the requirements of the design drawings, the board is cut and processed by CNC punching machine. And other equipment to form the required shape and size.

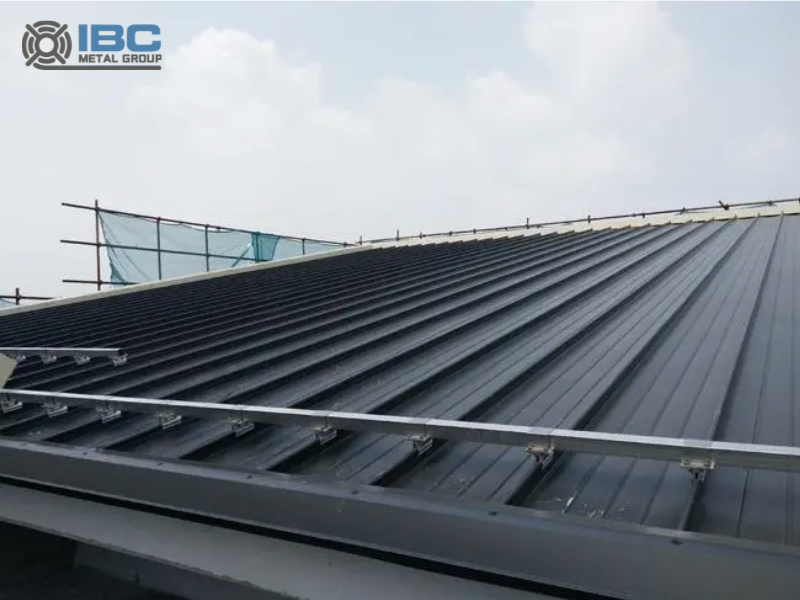

Assembly and welding: The cut plate and the supporting skeleton and other components are assembled and welded to form a complete roof panel system.

IBC Metal Group

Advanced production equipment and technology

IBC Metal Group has introduced a series of international advanced production equipment and technology . It can ensure the manufacturing accuracy and quality of metal roofing sheet. At the same time, the Group also continues to optimize the production process, improve production efficiency, reduce production costs. And we can provide customers with more competitive products.

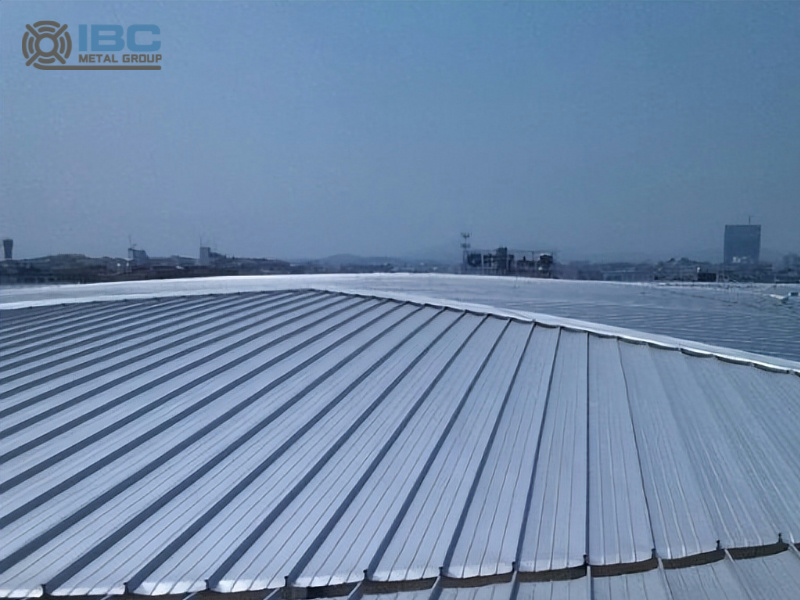

A wide range of products and specifications

IBC Metal Group can provide roofing panel products of various specifications and materials according to the needs of customers and the actual situation of the project. These products not only have good corrosion resistance, durability, wind pressure resistance and other characteristics. But they also have the advantages of beauty, environmental protection, energy saving and so on. At the same time, the Group can also customize production according to the special needs of customers to meet the individual needs of customers.

Strict quality control system

IBC Metal Group has established a sound quality control system, from raw material procurement, manufacturing to product inspection and other aspects of strict control. The Group has also passed ISO9001 quality management system certification and ISO14001 environmental management system certification. This can ensure that the quality and environmental performance of its products meet international standards.

Professional technical support and service

IBC Metal Group has a professional technical team, which can provide customers with a full range of technical support and services from solution design, product selection to construction and installation. At the same time, the group also provides after-sales service and technical consulting services. These ensure that customers can get timely and effective help and support in the process of use.

Contact with us today!