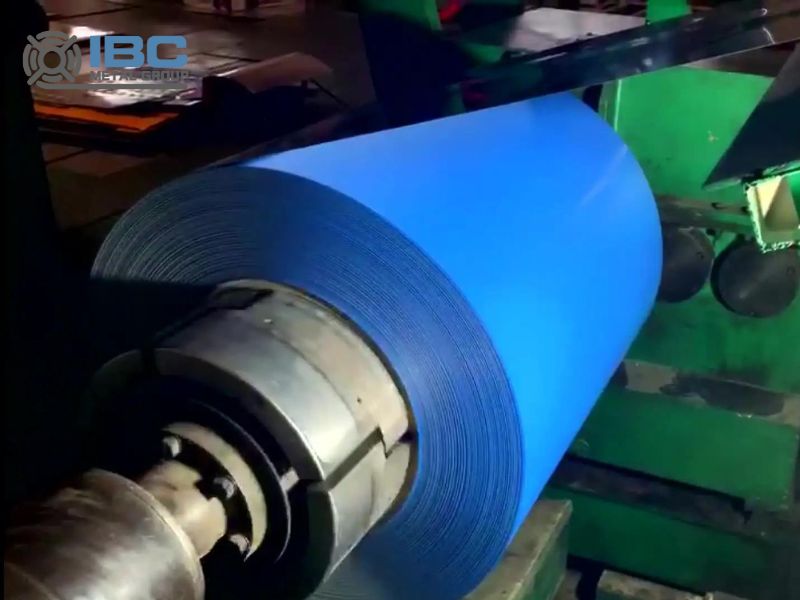

PPGI steel coil is based on galvanized coil and covered with colored paint to give the product more color. Because of its rich color and beautiful surface, it is very versatile. Construction, home appliances, furniture, public facilities, transportation and other fields are inseparable from its figure.

Coating of PPGI Steel Coil

PPGI Steel Coil is available in four basic coating types. When selecting the primer, the adhesion of the primer should be considered. For the top paint, corrosion resistance and color retention will be more important.

Four commonly use coatings: polyester (PE), silicone modified polyester (SMP), high-durability polyester (HDP) and polyvinylidene fluoride (PVDF).

What color is best? Mainly depends on the use of the environment, your preferences, market demand. For example, beauty is the first concern of civil architecture. But for industrial buildings, corrosion resistance is even more important. In addition, light-colored coatings have a greater ability to reflect heat.

Manufacturing Process

1. Substrate preparation: The substrate is usually cold-rolled or hot-rolled steel coils or plates that have been cleaned and pretreated to ensure that the surface is free of contaminants.

2. Coating treatment: The substrate surface is coated with one or more layers of a specific color and type of coating, usually including primer, coating and protective film. These coatings can provide anti-corrosion, anti-oxidation, weather resistance, wear resistance and other properties.

3. Processing and shaping: The coated steel coil is processed into the required coil or sheet by calendering, cutting and other processes.

Price Affecting Factors

1. The thinner the thickness, the higher the price.

For example, the price of 0.13-0.16mm is relatively high

The price change of 0.3-0.45mm is small

The price of 0.45 to 0.7 is basically the same

Reason: The thinner the color coated steel coil, the more meters per ton of steel coil, the larger the area, the more paint and longer processing time are required.

2.There is a big difference in price between a 20 gram zinc layer and a 50 gram zinc layer. If the customer has no requirements for the zinc layer, you can preferentially choose the steel coil with a zinc layer of about 30 grams, which is more cost-effective.

3.The price difference between 25% and 55% aluminum color coating is large. If the customer uses a general environment, you can choose a color coated steel coil with an aluminum content of about 25%. If used in humid, outdoor and year-round tropical climates, it is recommended to choose a color coating with a higher aluminum and zinc content.

4.Individual products in order to prevent scratching or have special effects required to cover the film will produce the cost of laminating.

Contact with us today!