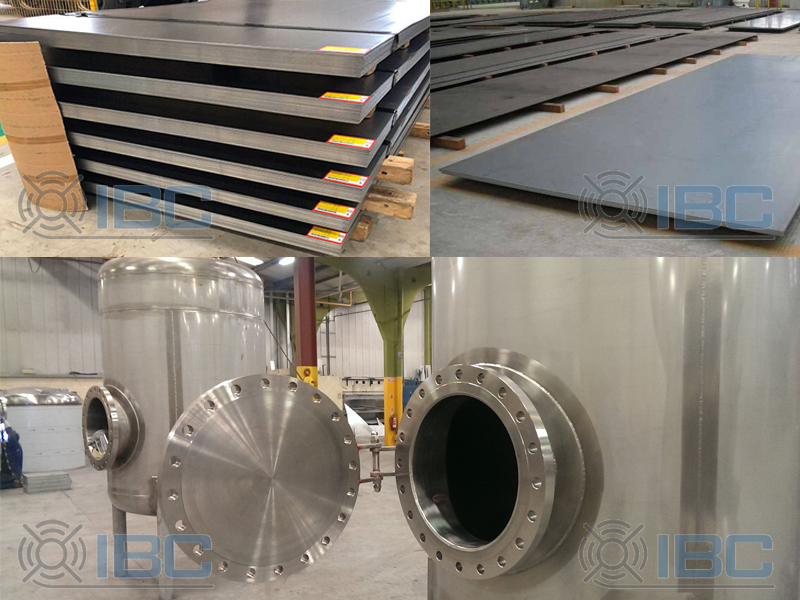

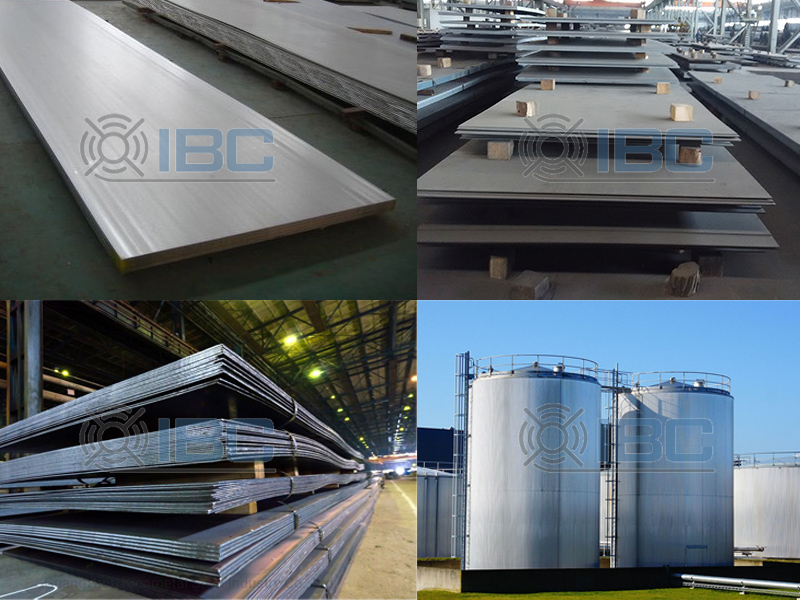

Pressure vessel steel plate has a variety of applications, most commonly in the energy and transportation sectors. For example, above-ground storage tanks are used to store chemicals and fuels, including oil, gas and petrochemicals. In addition, the production of liquid gas storage tanks and containers are also inseparable from this material.

Classification of Pressure Vessel Steel Plate

1.Carbon steel: Considering the weldability of steel, the carbon content of steel used for welding structural pressure elements should not be greater than 0.25%. That is to say, the carbon steel used for welding pressure vessels is low carbon steel. The carbon steel referred to in this material selection principle is low carbon steel.

2.Low alloy steel: It is a general term for low alloy high strength steel and pearlitic heat resistant steel. Among them, the low-alloy high-strength steel refers to the alloy steel with 3.0% less alloy content in order to improve the steel strength and improve the comprehensive energy for the main purpose.

3.Pearlite heat-resistant steel: Refers to the main purpose of improving the heat resistance and hydrogen resistance of steel, adding chromium Cr≤10%, molybdenum and other alloying elements of low carbon pearlite heat resistant steel. For example: 18MnMoNb, 15CrMo and other steel.

4.Austenitic stainless steel: Stainless steel with mostly austenitic microstructure at room temperature. For example, Cr18Ni9, Cr17Ni12Mo2.

5.Ferrite stainless steel: Stainless steel with mostly ferritic microstructure at room temperature. For example, Cr13A1.

6.Martensitic stainless steel: At normal temperature, the metallographic structure is mostly martensitic stainless steel. For example, Cr13.

Selection Principle of Pressure Vessel Steel Plate

(1)Carbon steel

When the wall thickness of the compression element is less than 8mm, carbon steel plates are used as far as possible. When the wall thickness of the compression element depends on the stiffness, carbon steel is preferred.

(2)Low alloy steel

When the wall thickness of the compression element depends on the strength, low carbon steel and low alloy steel are selected in turn under the premise of conforming to the scope of application. That is, 20R, 16MnR, 15MnVR and other steel plates.

(3)Pearlitic heat-resistant steel

Pearlitic heat-resistant steel is generally used for heat-resistant steel or hydrogen-resistant steel with a design temperature higher than 350 ° C.

(4)Austenitic stainless steel

lt is mainly used for corrosion resistance of materials or materials requiring clean and can not be contaminated by iron ions.When the required thickness is greater than 12mm, austenitic stainless steel composite steel should be preferred.

(5)Low-temperature steel

When the design temperature is less than or equal to -20 ° C, low-temperature steel (except for low stress) should generally be selected.

(6)Corrosion resistant steel

Under the condition of high temperature hydrogen, Nelson curve should be checked according to the hydrogen partial pressure (design pressure multiplied by volume percentage of hydrogen) and design temperature of the material to obtain the steel number suitable for the condition.

If you want to know more about this type of steel, you are welcome to call the consultation number below. IBC Group has won wide praise from customers over the years by virtue of its perfect service and rich products. Now has reached a win-win relationship with a number of customers around the world, very trustworthy.

Contact with us today!