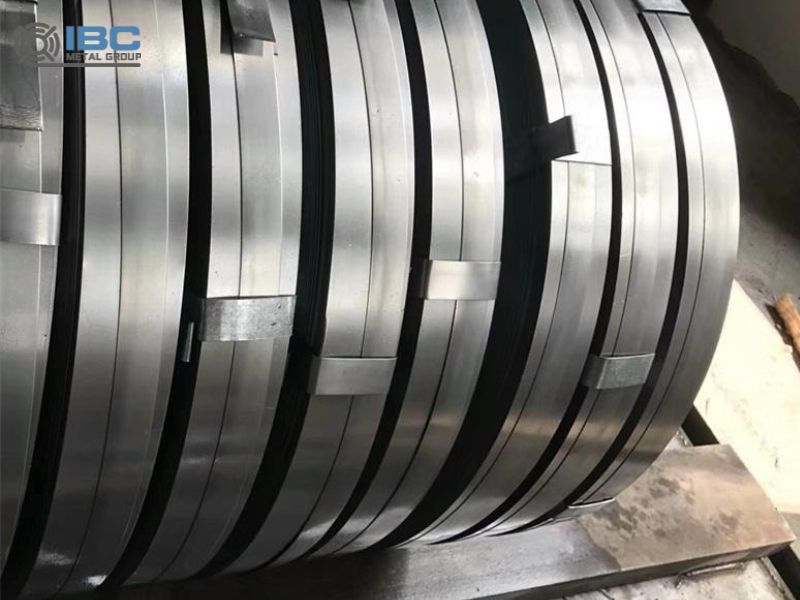

High carbon steel, also known as tool steel, is a steel with a carbon content between 0.60% and 1.70%. This steel can be quenched and tempered, so it has high strength, high hardness and good wear resistance. Because of these properties, it is widely used in the manufacture of products that require both hardness and toughness, such as cutting tools, knives, saw blades, springs, and automotive parts.

Properties of High Carbon Steel

1. High hardness: Its hardness can usually reach 60~65HRC, which makes it have excellent cutting performance and wear resistance. This high hardness makes the steel particularly suitable for manufacturing parts that need to withstand high loads, such as tools, blades and bearings.

2. High elasticity: Its elastic modulus is high, usually can reach 210~240GPa, giving it excellent elasticity and toughness. This characteristic makes this steel ideal for the manufacture of high-speed moving mechanical parts such as automobiles and trains, as well as parts such as springs that require high elasticity.

3. High strength: Its yield strength and tensile strength are very high, usually can reach 1200~2000MPa or more. This allows it to withstand large bending, compression and stretching forces. Therefore, it has a significant advantage in the manufacture of high-strength bolts and other structural parts.

4. Malleability: at high temperature, it has good forging and forming properties, which helps to manufacture metal products of various shapes.

Uses of High Carbon Steel

1. Tool manufacturing: Due to its high hardness and wear resistance, it is often used to manufacture a variety of tools, such as blades, saw blades, planing knives, etc. Among them, high-speed steel with other alloying elements is a special high carbon steel, with higher hardness and wear resistance, especially suitable for the manufacture of high-speed cutting tools.

2. Spring manufacturing: Its high elasticity and toughness make it an ideal material for manufacturing various springs, such as torsion springs, tension springs, pressure springs, etc. Among them, spring steel further optimizes elasticity and toughness by adding other alloying elements. And it is widely used in the field of spring manufacturing.

3. Bearing manufacturing: Its high strength and high hardness make it suitable for manufacturing a variety of bearings, such as ball bearings, roller bearings, thrust bearings, etc. Bearing steel has better strength and hardness and is widely used in the field of bearing manufacturing.

4, mechanical parts manufacturing: It can also manufacture a variety of mechanical parts, such as gears, shafts, pins, bolts, etc., these parts need to withstand greater mechanical stress and wear.

Contact with us today!