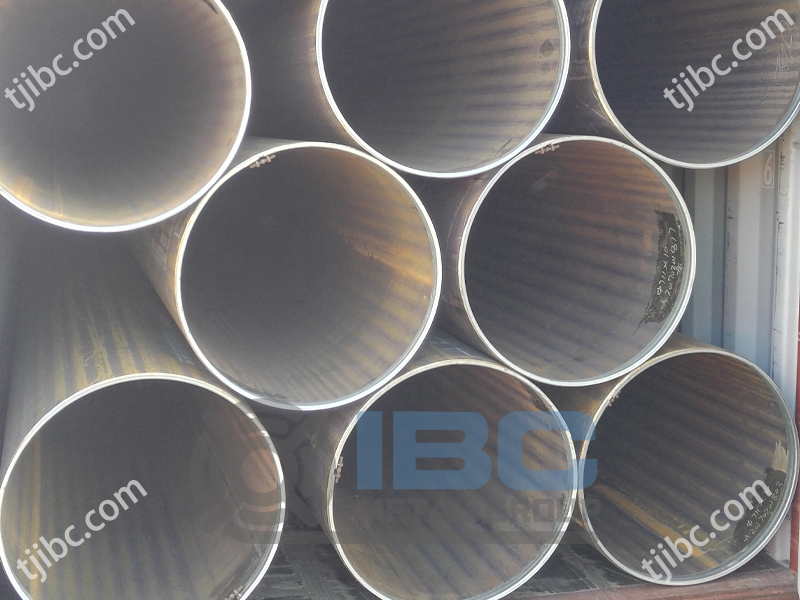

What is LSAW Steel Pipe?

LSAW Steel Pipe, say it in another way is Longitudinally Submerged Arc Welded Steel Pipe. As its name express, it weld seam is straight. Diameter above 914mm could prefer one weld seam or two weld seam.

Leaflets plates used as the raw material for Longitudinally submerged arc welding steel pipe (LSAW). In the mold or molding machine, pressure applied to form the steel plate into a variety of specifications. The process of double-sided submerged arc welding and flaring creates welds that are durable, ductile, consistent, and dense. Furthermore, these pipes come with high diameter, wall thickness, pressure resistance and low-temperature corrosion resistance – making them ideal for creating long-distance oil & gas pipelines that require strength and quality.

Longitudinally welded steel pipes used in onshore and offshore oil and gas pipelines requiring critical service, high performance, and tight tolerances. Construction projects also use LSAW pipes to convey flammable and nonflammable liquids.

LSAW pipes (longitudinal submerged arc welding pipes) formed by JCOE with one straight welded seam, usually between 323mm and 1420mm in outer diameter. A LSAW pipe can be welded with two straight seams above 914.4mm in outer diameter. It can convey low pressure liquids or high pressure petroleum or natural gas, and it can also used in foundations or structural supports. A benefit of LSAW pipes is that they can be made with thicker walls, up to 120mm in maximum.

Specifications of LSAW steel pipes:

- Outer Diameter: 406.4mm-15240mm;

- Wall Thickness: 5.0mm-40mm; We could do customized thicker wall thickness.

- Length: 6mtr-15mtr; If need longer pipes, could butt welded

- Pipe End: square ends (straight cut, saw cut, and torch cut). or beveled for welding, beveled.

- Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating /Anti rust oil.

Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydro-static Test, X-ray Test.

IBC Metal Group are a professional pipe and pipe fitting manufacturer, if you want to know more technical information, please contact with us today.

Contact with us today!