Peculiarity

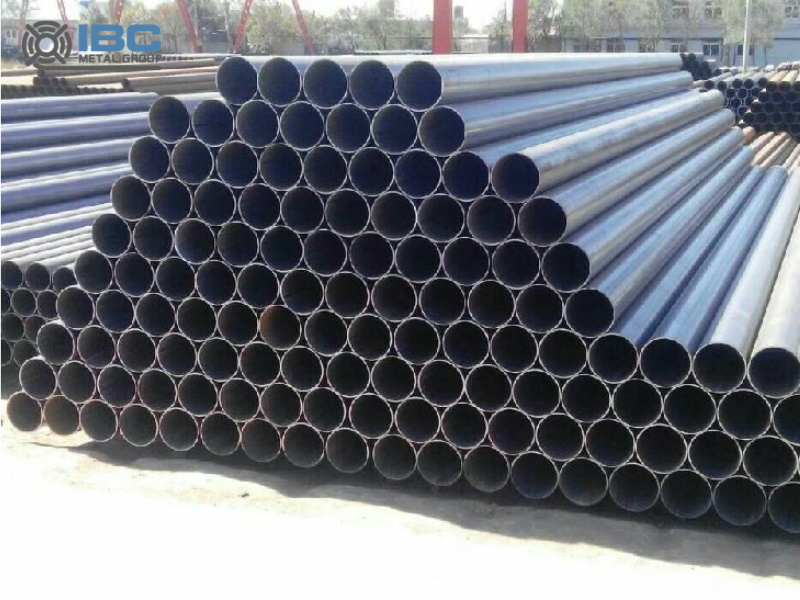

Wide range of specifications: LSAW pipe with a single thick plate as raw material, after a series of process processing, can produce a large range of specifications of the pipe, to meet different engineering needs.

High quality weld: The double-sided submerged arc welding method, the weld toughness, plasticity, uniformity and density is better, improve the overall quality and reliability of the pipe.

High strength and toughness: It is treated with integral mechanical expansion, and the internal stress is small and evenly distributed. This can effectively prevent stress corrosion cracking, so that it has a high strength and toughness.

High pressure resistance, low temperature resistance, corrosion resistance: It has the characteristics of large pipe diameter and thick pipe wall, can withstand high pressure. And it can still maintain good performance in low temperature environment. In addition, it also has a strong corrosion resistance, suitable for a variety of complex environmental conditions.

Widely used: It has a wide range of applications in oil and gas transmission, urban gas, chemical and other fields. Especially in the construction of high-strength, high-quality long-distance oil and gas pipelines, this pipeline is the preferred type of pipe.

Operation Mode of LSAW Pipe

Raw material preparation: Select a single medium and thick plate that meets the requirements as the raw material. This can ensure that the surface of the steel plate is clean, no rust, oil and other impurities.

Pretreatment of steel plate: pretreatment of steel plate such as trimming, rust removal and surface cleaning to ensure the quality of subsequent welding.

Groove processing: Grooves of a specific shape are cut on both sides of the steel plate. For example, V-shaped grooves, U-shaped grooves or X-shaped grooves can realize the docking of steel plates on both sides.

Steel plate assembly: Place the steel plates on both sides together and maintain a certain gap for subsequent welding operations.

Submerged arc welding: The welder places the electrode between two sheets of steel. The steel plates are then welded together by the action of electric currents and welding arcs. At the same time, they also need to fill the gap between the groove and the weld with melting flux. So the quality of the weld can meet the expected requirements.

Welding completion treatment: Clean and repair the welding parts, eliminate the oxides and residues generated in the welding process. And check and repair the defects of the weld to ensure the quality of welding.

Inspection and acceptance: Quality inspection and acceptance of LSAW pipes are carried out by means of X-ray inspection, ultrasonic inspection or magnetic particle inspection. It can ensure that they meet relevant standards and requirements.

Matters Needing Attention of LSAW Pipe

Steel plate selection: Steel plates with good quality, moderate thickness and in line with relevant standards and requirements should be selected as raw materials to ensure welding quality.

Steel plate pretreatment: Before welding, the surface of the steel plate should be thoroughly cleaned to ensure that there is no oil, rust and other impurities to avoid affecting the quality of welding.

Groove processing: The shape and size of the groove should meet the relevant standards and requirements. It can ensure the quality and strength of the welded joint.

Welding operation: During the welding process, parameters such as current, voltage and welding speed should be controlled. This guarantees the quality of the weld. At the same time, attention should be paid to prevent the production of welding defects, such as slag inclusion, porosity, etc.

Welding completion treatment: After the welding is completed, the welding parts should be cleaned and repaired in time to eliminate oxides and residues generated during the welding process. At the same time, the quality of the weld should be checked to find and repair defects in time.

Testing and acceptance: After the production of LSAW pipe is completed, quality testing and acceptance should be carried out in strict accordance with relevant standards and requirements to ensure that it meets the requirements of use. For unqualified steel pipes, they should be repaired or scrapped in time.

Contact with us today!