Where is reducer be used? Reducers are a type of pipe fitting that is used to reduce pipe diameter. The forming process is reducing diameter pressing, expanding diameter pressing or reducing diameter plus expanding diameter pressing, and stamping forming. Let’s look at when we will need it.

1. When the flow rate changed in the pipeline, such as increasing or decreasing, which required one.

2. At the inlet of the pump, in order to protect pipe against cavitation, it is necessary to use reducer.

3. At the joints with instruments, such as flow meters and regulating valves, in order to cooperate with the joints of the instruments, which required that.

Types of Reducer

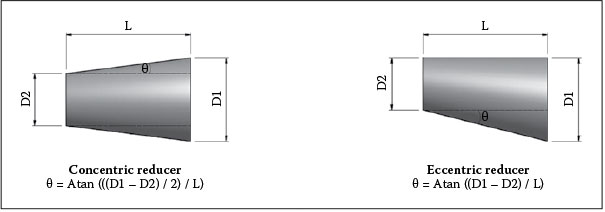

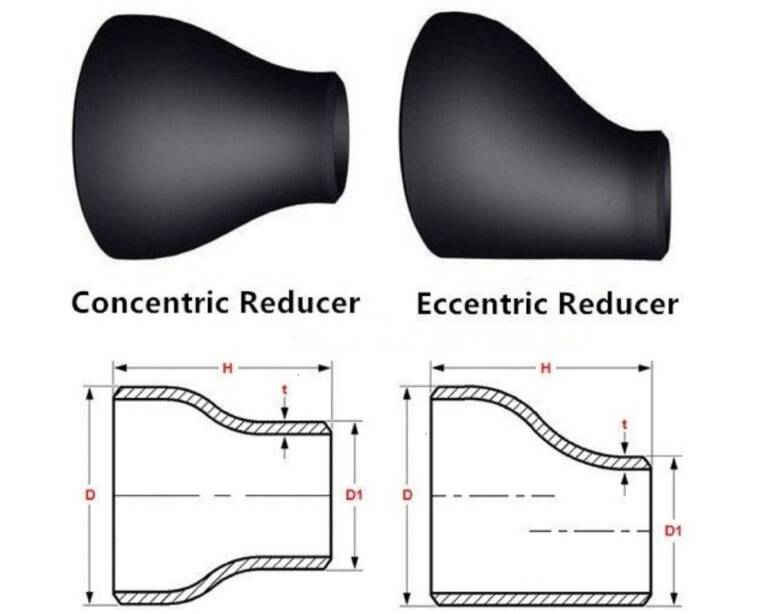

There are two main types of reducer: one is Concentric reducers. The other one is Eccentric reducers. Reducers are usually concentric but eccentric reducers are used when required to maintain the same top-or bottom-of-pipe level.

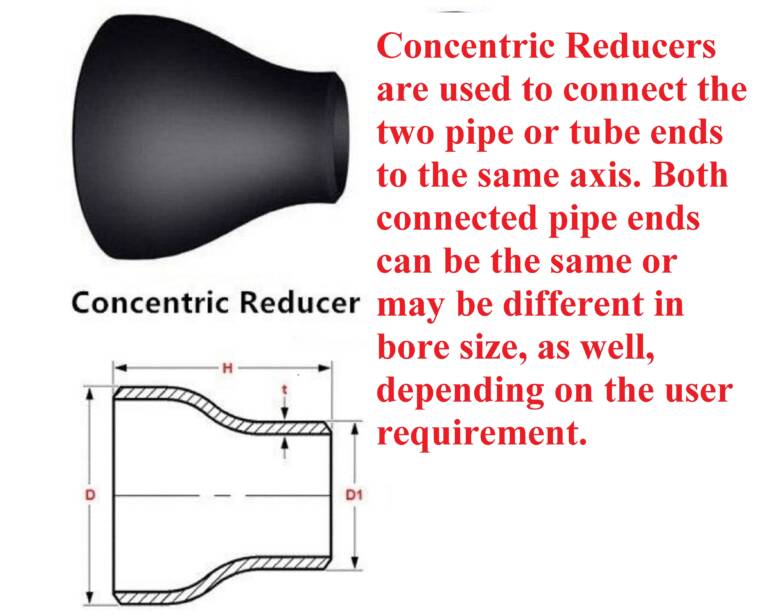

(1)Concentric Reducer

The Concentric one designed to reduce the diameter of a fitting at an even rate across a specific length, maintaining its symmetry around the device. Not only can it used to join pipes or tubes with different diameters along the same axis, but they also provide an in-line conical transformation between pressurized pipes of varying diameters with one shared center line. This same fitting can used in reverse as a concentric expander.

(2)Eccentric Reducer

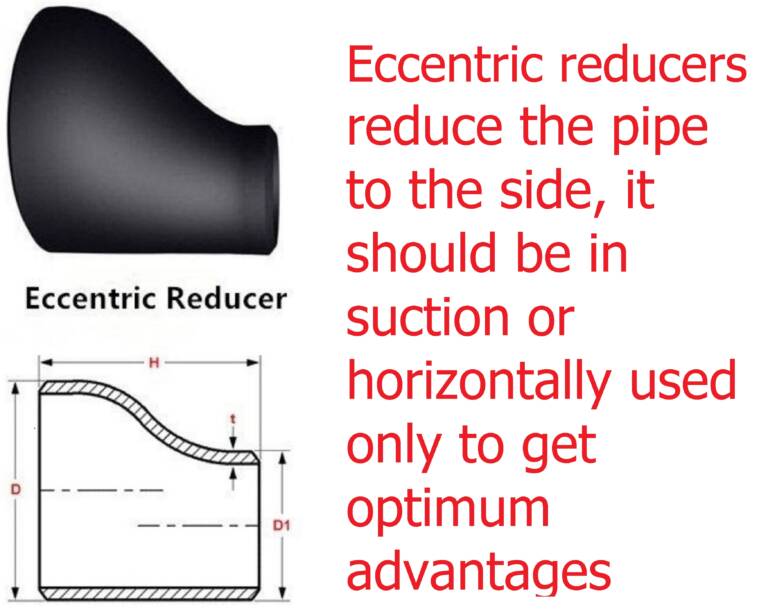

When using Eccentric Reducers, the pipe size reduced by decreasing its diameter at a steady rate over a specified length, while maintaining one side of the fitting horizontally. An eccentric pipe reducer fitting manufactured with the smaller outlet off center to the larger end, allowing it to align with only one side of the inlet. As an eccentric expander, the same fitting can also use in reverse.

In the industries, there are two kinds of reducers: concentric reducers and eccentric reducers. The eccentric reducers keep the service flow at the same level at the top or bottom of the pipe in the piping system. In pipe piping, we use a reducer to join two pipes with different diameters.

How to Select

After we know where is reducer be used, we need to know how to select it. There are many parameters for selecting an appropriate pipe reducer, some of the important given below.

- Choose DN (nominal diameter) and schedule 1st pipe end like (100NB X 25NB).

- Choose DN (nominal diameter) and schedule for 2nd pipe end (small pipe bore)

- Distance from one pipe end to another pipe end

- Select the dimensions standard for it ASME B16.9 (Butt weld fittings, MSS SP-43, ASME B36.19, MSS SP-43)

- Select the design standard for reducer.

- Process of reducer fitting made (Seamless or ERW, Electric resistance welding).

- Select the (MOC) materials of construction for your fitting, like mild steel (MS), stainless steel (SS), Corbon Steel, Monal, etc.

- Select Class or Pressure rating or Schedule, according to your piping design.

- What is type of Reducer (eccentric or con-centric) select as per your requirement?

- What is type of end connection required, Plane end (PE), Bevel end, Flange end.

- Types of weld required Socket weld or Butt weld.

- Corrosion resistance

- Durability

Note- For thumb rule and general rule for safety and to get appropriate output for the designed system the reducer Wall Thickness should not be less than 87.5% of Nominal Wall Thickness.

Conclusion

Using a reducer, you can reduce the pipe size (inner diameter) from a larger bore to a smaller bore (inner diameter) in process piping. By using a it, the pipe size can change to meet hydraulic flow requirements or to accommodate existing pipe size changes. Reductions are usually as long as the average of the larger and smaller pipe diameters.

We offered reducers in many materials and sizes to meet the demands of end users. Knowning commonly as reducing TEES, they used to connect a branch to the main pipe, usually at 90°, and may be of the same or different diameters. Reducers are more affordable than their reducing TEES counterpart and easy to construct, as well as being lightweight. It’s even possible to construct eccentric type reducers on-site by a fabricator. Additionally, reducers can reverse for use as expanders if desired–the same is true for olets such as weldolet, sockolet, latrolet and thredolets.

1