Which fields are low temperature alloy steel pipe used in? Low-temperature alloy steel pipe has a lot of advantages, including high strength, long service life, wide applications, and cost-effectiveness. Usually rolled into plates, profiles, seamless steel pipes, etc., it widely used in chemical industries, pipeline transportation, mining engineering, and other industries that require low temperatures.

What is Low Temperature Steel Pipe?

This type of steel pipe has medium carbon content, used in both cold and hot conditions, and has good mechanical properties, a low price, and a wide source, making it widely used. Low hardenability, large section sizes, and high workpiece requirements make it unsuitable for use.

How do Alloying Elements Affect the Performance of Cryogenic Steels?

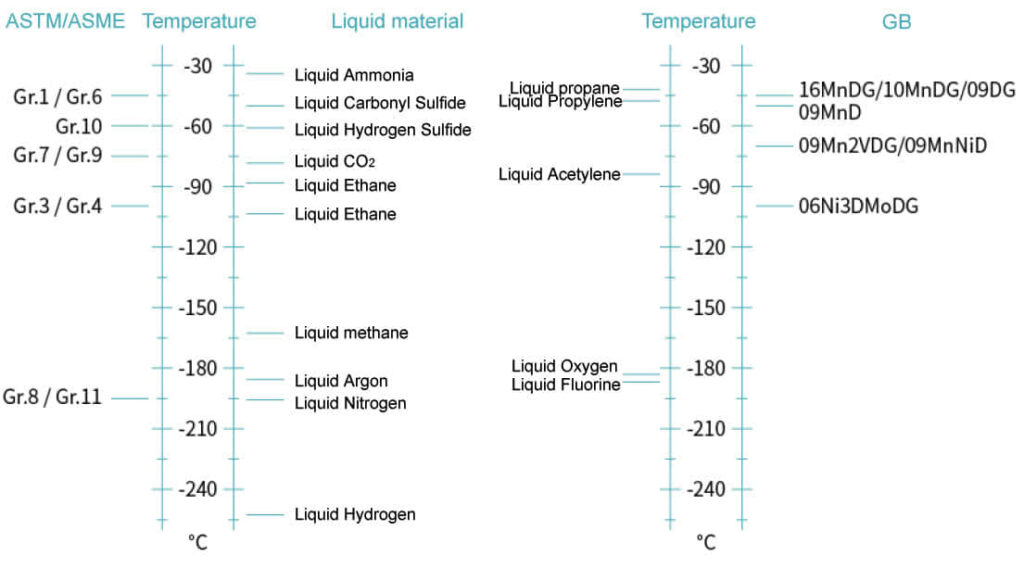

Low-temperature steel, also known as cryogenic steel, usually used in temperatures from -10 to -273℃. Variations in alloying element content and structure divide cryogenic steels into several categories: Aluminum killed C-Mn steels (e.g. 06MnVTi, 06MnVal, 09Mn2Vre, 06MnNb) low alloy ferric body variants (0.5Ni, 2.5Ni, 3Ni, 3.5Ni etc.), Martensiform grades (9Ni and 5Ni), high alloy austenitic varieties (1Cr18Ni9Ti and 20Mn23Al) among others. The main effect of alloy elements on low-temperature steels is its impact on their low-temperature toughness.

Mn Elements

Manganese is a key element in steel, as it can markedly improve its low-temperature toughness. It mainly exists as solid solution, strengthening the steel to a great extent, and also enlarges the austenite region while decreasing the transformation temperature (A1 and A3). Moreover, it facilitates in producing finer and more ductile ferrite and pearlite grains, which subsequently raises the maximum impact energy and decreases the brittle transition temperature. To achieve optimal results, an Mn/C ratio of 3 usually desired – this not only lowers the brittle transition temperature but also reverses any loss of mechanical properties due to increasing Mn content leading to lower carbon concentration.

Ni Elements

Nickel can lessen the tendency of brittle change and reduce the temperature of brittle transition significantly. Compared to manganese, it is 5 times more effective at enhancing the low-temperature toughness of steel; 1% increase in nickel content means a 10℃ drop in its brittle transition temperature. This owed mainly to nickel’s combination with carbon, which solidifies via absorption and reinforcement as well as shifting the eutectoid point of eutectoid steel to lower carbon content, reducing thus the phase transformation temperature (A1 and A2), with fewer amount of ferrite plus finer and lessened carbon-content pearlite compared to usual carbon steel. Experiments have revealed that nickel increases low-temperature toughness due to the fact that it allows for more mobile dislocations at a low temperature which aids in cross slip. For example, 9Ni medium alloy low carbon martensiform low-temperature steel maintains high toughness even at -196℃, while 5Ni steel based on this has good resilience between -162~-196℃.

C Elements

With the increase of carbon content, the brittle transition temperature of steel increases quickly and the welding property decreases. So the carbon content of low-temperature steel limited to less than 0.2%.

P, S, Sn, Pb Sb Elements

These elements – phosphorus, sulfur, arsenic, tin, lead and antimony- are not good for the cold hardiness of steel. Concentrating in the grain boundary, they lower its surface tension and susceptibility to fracture. The result is that cracks can start out at the grain boundary and propagate through it until complete rupture. Though increasing the strength of steel, phosphorus should keep within limits as a rise in the brittle transition temperature is observed.

O, H, N Elements

Using deoxidized silicon and aluminum killed steels can help increase the toughness at low temperatures, however due to the introduction of silicon, aluminum kills steel tends to have a lower brittle transition temperature in comparison to other silicon based types. Low-temperature alloy steel pipe typically contains grade A and B steel plus certain levels of silicon or manganese with additional traces of vanadium (V), niobium (Nb), titanium (Ti), aluminum (Al), molybdenum (Mo), nitrogen (N) and rare earths (RE). This type of steel typically follows Q345A, B, C, D and E standards, with grades A and B being commonly referred to as 16Mn or Q345B.

Which Fields are Low Temperature Alloy Steel Pipe Used in

There are many kinds of materials used for transport in industrial production. Specifically we will have more choices and it not limited to the use of alloy steel pipe. But even in the face of more choices, many people tend to choose alloy steel pipe. People make their own choices will have their own reasons. This means the alloy steel pipe application has its own advantages. Compared with transmission lines made of other materials, after it meets the basic application requirements, its quantity is lighter. Then in the practical application of alloy steel pipe, it will have more advantages because of this. Besides its physical characteristic advantage, it also has economic advantages. The wide application of alloy steel pipe is with kinds of reasons. So in practical usage, we can exploit the advantages to the full. In this way can we get more profits in these applications of alloy steel pipe.

What Requirements Should Alloy Steel Pipe Application Meet

The use of alloy steel pipe is essential when transporting various gasses or liquids in production. As it can withstand a wide range of temperatures and offers greater corrosion resistance than other materials. This makes them suitable for transporting different types of materials with varying temperatures. And provides convenience for those that need it.

The Biggest Advantages of Alloy Steel Pipe

High-pressure alloy steel pipes are 100% recyclable and good for the environment, helping to conserve energy and resources. This is consistent with China’s strategy and policy of encouraging their use. Although they only make up half of the proportion consumed in comparison to developed countries. There is still potential for growth in this area, as the average annual demand for these pipes in China estimated to increase by 10-12%.

Contact with IBC Metal Group Today!