What is ASTM A53 for Building Structural?

ASTM A53 carbon steel pipe is an alloy pipe created for low to medium-pressure applications. Its versatility makes it ideal for multiple uses, from oil and gas structures to construction projects and plumbing. Developed by the American Society for Testing and Materials (ASTM), the ASTM A53 standard specification known as “Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless”. This comprehensive standard covers seamless as well as welded black or hot-dipped galvanized steel pipes. The properties specified in this standard ensure that ASTM A53 Grade A is a material of choice when it comes to structural steel or pipelines in need of lower pressure levels.

ASTM A53 Carbon Steel Seamless Pipe Specifications

ASTM A53 is a standard of the American Society for Testing and Materials with sizes ranging from NPS 1/8” to NPS 26”. The pipes feature different wall thicknesses, including Schedule 10, 20, 30, 40, 60, and 80. The finishes available for these pipes are black and hot-dipped, zinc-coated, welded, and seamless. One can use them for pressure applications as well as ordinary uses in steam, water, gas, and air lines.

Types of ASTM A53 Pipes

A53 pipe comes in three types (F, E, S) and two grades (A, B).

– ASTM A53 Type F – Furnace-Butt Welded Continuous Welded Pipe

A furnace butt weld or continuous weld used to manufacture Type F pipe longitudinally (Grade A only). The Type F Grade A pipe manufactured from a continuous coil. And the longitudinal junction welded by forging. The heated ends of the coil mechanically compressed by sets of rollers in this procedure.

– ASTM A53 Type E – Electric Resistance Welded Pipe.

In Type E Garde A and Garde B pipes, the longitudinal junction welded by heat generated by electrical resistance. The longitudinal junction between the pipe’s opposite ends formed by the continuous coil. The weld seams of Grade pipes are heat-treated to a minimum of 540°C after welding. Type E pipes have an electric resistance weld longitudinally (Grades A and B).

– ASTM A53 Type S – Seamless Pipe

Extrusion used to make Type S pipes. A basic oxygen process, an open-hearth furnace, or an electric furnace used to produce the raw steel needed to make pipes. A seamless pipe of Type S made by hot working and maybe cold finishing, and is available in Grades A and B).

IBC (Tianjin) Industrial Co.,Ltd renowned for its ample supply of ASTM A53 steel pipes (ASME SA53 steel pipes). Our most popular products under this specification are ASTM A53 Grade B Seamless, which is often dual certified to the A106 B Seamless pipe. Meanwhile, ASTM A53 Grade B and API 5L Gr.B are American steel pipe standards while A53 GR.B ERW and API 5L GR.B Welded pertain to their respective electric resistance welded and welded pipes.

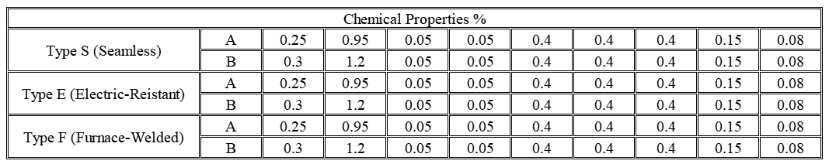

Chemical Composition of A53 Steel

The chemical composition of A53 steel varies depending on the grade and type. Grades B in types S, E and F have similar compositions, with a higher level of manganese than grade A for types S and E (up to 0.30 percent more) and also featuring up to 0.05 percent extra carbon. This can be found in the following table:

*The total composition for these five elements shall not exceed 1.00%

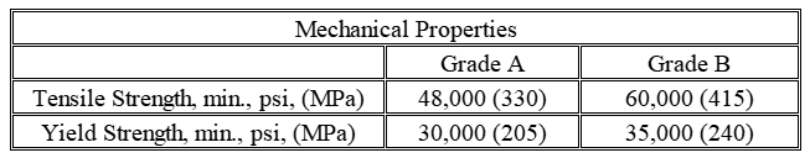

Mechanical Properties of ASTM A53 Steel

Mechanical properties are used to help classify and identify material. The most common properties dealt with in construction materials are strength, modulus of elasticity and Poisson’s ratio. The mechanical properties include:

(Note: This is summarized information from ASME Specification A53. Please refer to the specific Standard or Specification or contact us for more details.). ASTM A53 seamless steel pipe is an American standard brand. A53-F corresponds to China’s Q235 material, A53-A corresponds to China’s No. 10 material, and A53-B corresponds to China’s No. 20 material.

Production process

Seamless steel pipe manufacturing process is divided into hot-rolled and cold seamless pipe.

1. Production process of hot-rolled seamless steel pipe: tube billet → heating → perforation → three-roller/cross-rolling & continuous rolling → de-pipe → sizing → cooling → straightening → hydraulic test → marking → seamless steel pipe with leverage effect detected.

2. Production process of cold drawn seamless steel tubes: tube blank → heating → perforation → heading → annealing → pickling → oiling → multiple cold drawing → blank tube → heat treatment → straightening → hydraulic test → marking → storage.

Applications of ASTM A53 Steel

– ASTM A53 Pipes for Oil & Gas

The use of A53 steel gives it a relative advantage. The chemical composition of A53 makes it unsuitable for applications requiring low or medium pressures, such as oil, steam, air, or water transportation. Silicon, an alloy that increases heat resistance, is absent from A53, thus preventing its use for high-temperature transportation.

– ASTM A53 Pipes for Structural Steel

A wide range of diameters and grades are available, which allows ASTM A53 pipe to be used for a variety of different structural applications as well as for various structural functions. A structural pipe can be used for a variety of purposes, including columns, bollards, sign poles, structural supports, and pilings.

– ASTM A53 Pipes for Metallic Conduit

ASTM A53 conduit pipes are durable steel enclosures that protect electrical wiring conductors from impact, moisture and chemical vapors. These pipes come in various categories depending on the thickness of the walls, joint rigidity and material construction. The galvanized tubes feature a wall thickness suitable for threading and are coated with a protective lacquer on the outside, while zinc is blown off the inside to prevent buildup. This makes ASTM A53 pipes easy to bend, thread or cut due to its excellent ductility.

– ASTM A53 Pipes for Conveyor Roller

ASTM A53 conveyor roller pipes help transport products or bulk materials, such as coal, sand, or iron ore, along a conveyor belt. These pipes are essential to keep the whole system running; their purpose is to support the belt as it moves from one drum to another. Pulleys also contribute to the operation of the conveyor belt, providing traction and directing it in the desired direction – more details on this can be found in our blog post. Thus, both pulleys and roller pipes are necessary components for successful conveying.

In Brief:

- 1. Construction: the pipeline underneath, the groundwater, and the hot water transportation.

- 2. Mechanical processing, bearing sleeves, processing machinery parts, etc.

- 3. Electrical: Gas delivery, Hydroelectric power fluid pipeline

- 4. Anti-static tubes for wind power plants, etc.

- Go here if you are looking for the “ASTM A106 Steel Pipe Specifications”

Conclusion

Overall, ASTM A53 Carbon Steel Pipes offer a multitude of advantages for any application that requires dependable yet robust steel piping solutions. From bridges to automotive components to building structures, this type of steel pipe is sure to meet all requirements with its excellent quality standards both now and in the future. Its affordability, durability, and versatility make it a favorite choice – no surprise why it’s such a popular option. Here at our company, we offer various types of products like ASTM A333 GR.1 Pipes.

Contact with IBC Group Today!