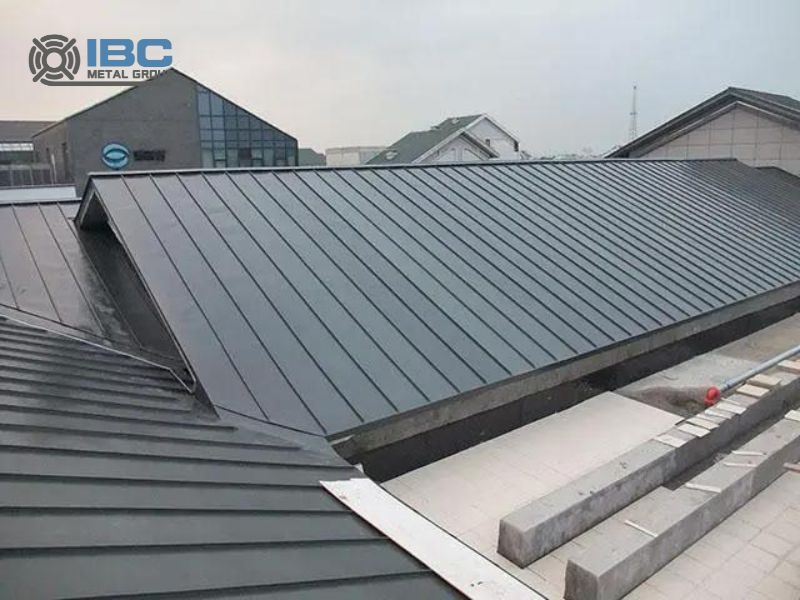

Aluminum roofing sheet is a building material, made of aluminum alloy, used to cover the roof of a building. It has many advantages, such as light weight, corrosion resistance, fire protection, easy installation and maintenance. Compared with traditional tile or iron roofing, this roof panel is more beautiful, durable and practical.

Advantages of Aluminum Roofing Sheet

1. Light weight and high strength: the density of aluminum is low, only about one-third of steel. Therefore, its weight is light, but its strength is very high, and it has good bearing capacity and seismic performance.

2. Corrosion resistance, waterproof and moisture-proof: The naturally formed oxide layer of aluminum can effectively resist the erosion of moisture and chemical substances. So this roof panel has good corrosion resistance and waterproof and moisture-proof performance, and long service life.

3. Easy installation and maintenance: its installation is simple and fast, the construction quality is easy to ensure, and no special maintenance is required. It can save a lot of installation and maintenance costs.

4. Beautiful and diversified: its surface is specially treated to show a variety of colors and textures. It has good decorative effects and can meet the needs of different architectural styles.

Installation Method 1

1. Release cables

Pay-off is the first step in the installation of aluminum roofing panels, the purpose of which is to determine the exact position and direction of the roofing panels. First, according to the architectural design drawings, mark the beginning and end points of the roof panels on the roof, and use ink lines or lines to mark. Ensure that the marks are clear and accurate, so that subsequent installation work can be carried out smoothly.

Step 2 Get in position

Placement is the process of placing the roof panels on the roof, block by block, according to the location marked by the payout. Before installation, it is necessary to check whether the size, color and texture of the roof panel meet the design requirements. And we need ensure that the surface of the roof panel is free from damage and stains. When in place, pay attention to the gap and alignment between the roof panels to ensure that the overall effect is beautiful and coordinated.

3. Bite

Occlusion is an important step in the process of roof panel installation. Its purpose is to closely connect adjacent roof panels together to enhance the stability and tightness of the overall structure. This type of roof plate is usually occluded by a specially designed lock or lap joint, and the specific operation method should be carried out according to the product description of different types and brands of roof plates.

Installation Method 2

4. Trim

During the installation of aluminum roofing sheet, it may be necessary to trim some roofing panels to adapt to the special shape or size requirements of the roof. When trimming, professional metal cutting tools should be used to ensure that the cutting surface is smooth and smooth, and does not affect the overall beauty and use effect of the roof panel.

5. Flanging treatment

Flanging is a special treatment step for the edge of aluminum roofing panel to enhance the wind pressure resistance and waterproof performance of the roofing panel. This process is usually carried out with professional flanging machines or hand tools. Workers will fold the edge of the roof panels at an Angle, so that it can better integrate with the roof base, forming an effective waterproof barrier.

Contact with us today!