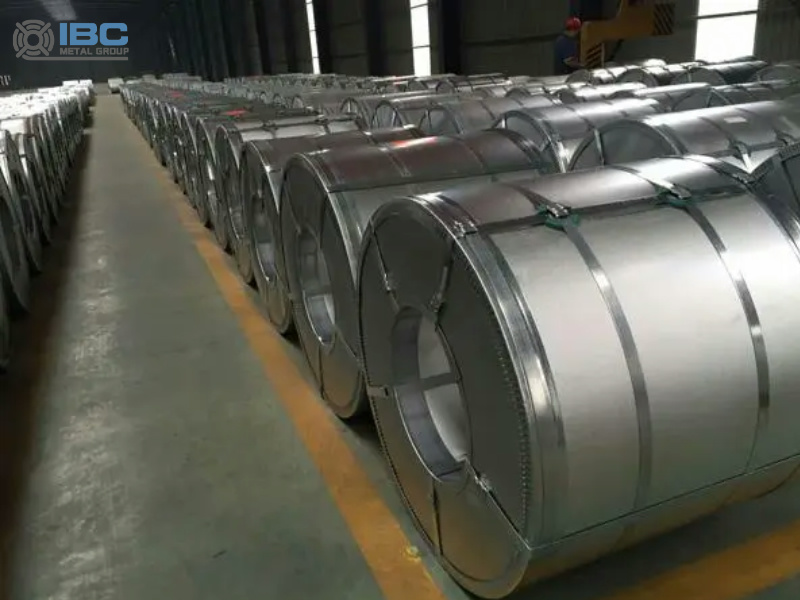

Aluzinc Galvalume Steel Coils are a kind of metal plate. They are made of cold rolled hard steel plate as the base plate, after pickling, rust removal, coating and other processes, and then by hot dip plating aluminum-zinc alloy layer.

This plate is characterized by a layer of aluminum-zinc alloy coating on its surface, which gives it excellent properties such as corrosion resistance, oxidation resistance, fire resistance and scratch resistance.

Performance of Aluzinc Galvalume Steel Coils

1. Appearance effect: Its surface has been measured and sandblasted to form a high surface finish and coating effect, which not only enhances the beauty of its appearance, but also improves its corrosion resistance and aging resistance.

2. Corrosion resistance: This steel coil has excellent corrosion resistance, and its surface can resist damage under various climatic conditions, especially the erosion of acid rain. This corrosion resistance is mainly due to the barrier maintenance function of aluminum, which forms an insoluble oxide layer. And the dedicated maintenance function of zinc. It provides protection when needed, thus ensuring the durability of the material.

3. Heat resistance: It has a high thermal reflectivity, so it is very suitable for use as a roof material. At the same time, it also has excellent heat resistance and can remain stable in an environment of up to 315 degrees.

4. Easy processing: it has good processing performance and can be processed by various processing methods such as hot dip galvanizing equipment, cold rolling equipment and rolling equipment to meet the requirements of different occasions. Whether cutting, stamping or welding, aluminum coated zinc coil can show good processing characteristics.

5. Easy installation: Its installation process is simple and convenient, and it can be quickly fixed on the building surface by drilling and pasting, which greatly saves the installation time and cost.

Superior Quality and Durability | IBC Metal Group

First, from the characteristics of the coil itself, it has significant corrosion resistance, heat resistance and recoating (paint film adhesion). These characteristics enable aluminum-plated zinc coils to maintain excellent performance in a variety of environments. It has a normal service life of up to 25 years and can be painted or dusted without special pre-treatment. Therefore, IBC Group strictly controls the quality during the production process to ensure that the products meet or even exceed these standards, so the quality of Aluzinc Galvalume Steel Coils is higher.

Secondly, IBC Group has advantages in technology research and development and process innovation. Through continuous technological innovation and process improvement, the company can optimize the production process and improve the performance and quality of the products. We use advanced production equipment and technology to ensure the uniformity and stability of the coating. In addition, by optimizing the production process, the factory reduces the defects and defective products in the production process.

In addition, IBC Group also focuses on the selection and quality control of raw materials. High quality raw materials are the key to producing high quality products. The company can choose high-quality aluminum, zinc and other raw materials, has won the broad trust and love of customers.

Contact with us today!