Performance Advantages

1. High intensity

Duplex steel has a higher strength than ordinary steel, which allows it to withstand greater loads. In practical applications, its high strength characteristics can make parts or structures that need to withstand high loads. For example, in bridge construction, high-rise buildings, aerospace and other fields, it is an ideal material choice.

2. Excellent ductility

This kind of steel not only has high strength, but also has good ductility and plasticity. This means that when stressed, it can undergo large deformation without breaking. This characteristic gives it greater flexibility during processing and manufacturing. By making proper use of its malleability, parts and products with more complex shapes and more precise dimensions can be manufactured.

3. Good corrosion resistance

The corrosion resistance of this steel is better than that of ordinary steel. This makes it suitable for long-term use in wet or corrosive environments. In order to give full play to this advantage, the fields that need to withstand corrosive environments (such as chemical, petroleum, offshore engineering, etc.) are inseparable from it. Workers can effectively extend the service life of equipment or components by choosing the right materials and reasonably designing the structure.

4. Weldability

It has good weldability, which means that it can be machined and joined by welding. This characteristic gives it greater flexibility in the manufacturing process. When metal parts need to be joined or repaired, workers can use the welding process to join steel parts together. In order to ensure the quality of welding, they should choose the appropriate welding method and process parameters. And carry on the necessary inspection and evaluation to the welded joint.

Applications of Duplex Steel

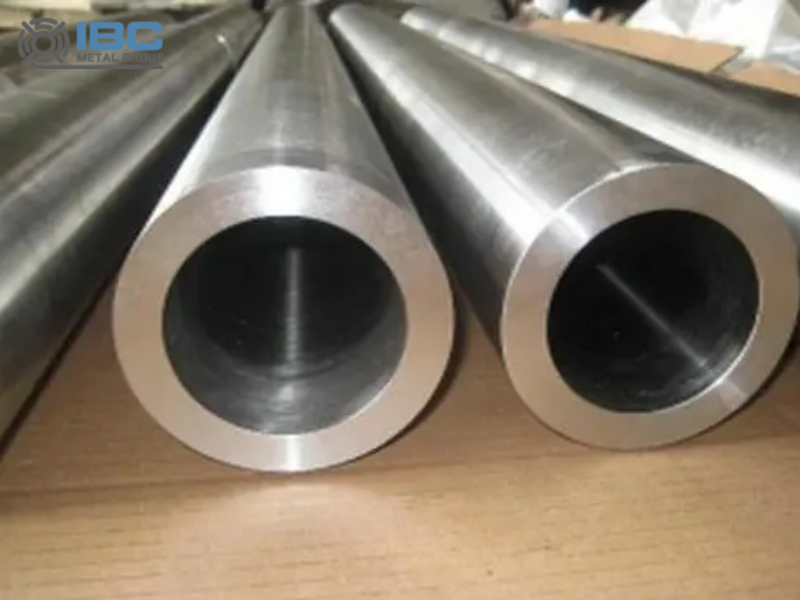

- Chemical and Petroleum Industries:

In the chemical and petroleum industries, duplex steel can be used to make pipes, containers, valves and other equipment. Due to its excellent corrosion resistance and high strength, these devices can ensure safe and stable operation in harsh chemical environments.

When operating, it is necessary to ensure that its material selection matches the specific process requirements. And through precise processing and welding technology, the equipment is manufactured to meet the standards.

- Food Processing and Manufacturing:

It has a smooth surface and is easy to clean and maintain, making it ideal for food processing and manufacturing. In these industries, it makes equipment, pipes, etc.

When operating, it is necessary to ensure the cleanliness and hygiene of the steel, and adopt appropriate cleaning and disinfection measures to ensure the safety and health of the food processing process.

- Shipbuilding Industry:

This steel is the ideal material for Marine structural parts, pipes, storage tanks, etc., which require excellent corrosion resistance and strength.

In the shipbuilding process, it is necessary to select the appropriate steel type and specification according to the specific requirements of the ship, and adopt the appropriate processing and welding technology to ensure the stability and safety of the hull structure.

- Medical device and Pharmaceutical Industry:

Duplex steel has excellent corrosion resistance and biocompatibility. And it is suitable for the manufacture of medical devices and equipment, containers in the pharmaceutical industry.

In these areas, it is necessary to ensure the purity and biosafety of steel, and to manufacture equipment that meets medical and pharmaceutical standards through sophisticated processing and inspection techniques.

Advantages of IBC Group

- Customized service

IBC Group can provide customized steel products and solutions according to the specific needs of customers. For example, steel with specific specifications, materials and properties is customized according to the project size, use environment and special requirements of the customer.

- Technical support

The group has a professional technical team, can provide customers with technical advice, program design, installation guidance and other comprehensive technical support. This helps ensure that customers get the best performance and benefits during use.

- Quality assurance

The group strictly controls product quality and adopts international advanced production technology and equipment to ensure excellent performance and reliability of products. At the same time, the Group also through a strict quality testing and certification system to ensure that products comply with relevant standards and regulations.

- Fast response

The group has a perfect service network and rapid response mechanism, which can quickly provide technical support and after-sales service when customers need it. This helps to ensure that the customer’s production runs smoothly and reduces the losses caused by equipment failures.

- Sustainable development

IBC Group focuses on sustainable development and actively promotes environmentally friendly, energy efficient and low-carbon production methods. At the same time, the Group also provides customers with environmentally friendly steel products and solutions to help customers achieve green production.

Contact with us today!