How many types of corrugated roofing sheet in the industrial world? When we talk about corrugated roofing sheet, firstly, we need to know what the corrugated roofing sheet is. And how many types of it? What kinds of materials they are?

What is Corrugated Roofing Sheet?

Corrugated roofing sheet is a type of roofing material that consists of panels with wave-like shapes. It usually made from metal, cardboard, or plastic or other materials. These waves give the panel strength and rigidity, while also allowing it to be lightweight and easy to install. These panesl are than attached to the roof with screws. Corrugated roofing is often used on commercial and industrial buildings, as well as on sheds and other structures where a strong but lightweight roof is needed.

Different Types of Corrugated Roofing

There are a variety of corrugated roofing sheet types available on the market, each with their own benefits. The main five types material of corrugated roofing is metal (including Galvanized corrugated roofing sheet and aluminum roofing sheet), polycarbonate, Bitumen, asphalt-coated fiberglass (also called Fibre Cement), and PVC one.

Metal Corrugated Roofing Sheet

The first one, the most common type of corrugated roofing sheet is made from galvanized steel. These sheets are strong and durable, but can be susceptible to corrosion over time. And aluminum corrugated roofing sheets are a lighter weight alternative to steel sheets, but are also more expensive.

As with all forms of corrugated sheeting, the undulating design allows for effective drainage as well as increased impact resistance. This outstanding strength is shown most prominently in corrugated metal roofing sheets. Thanks to their aluminium or galvanised steel construction, these sheets are both relatively lightweight and incredibly strong. As a more ‘heavy duty’ option they are much more suited to larger commercial and agricultural builds like warehouses or barns and, in some cases, can last up to a hundred years.

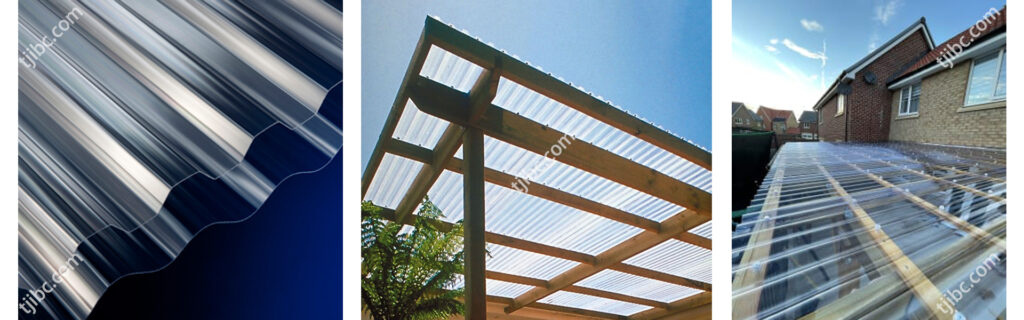

Polycarbonate

Secon one, is Polycarbonate corrugated roofing sheets are among the strongest and most weather-resistant options, but they can be more difficult to work with. Polycarbonate is an extremely strong material, with corrugated polycarbonate sheets being virtually unbreakable and resistant to damage from UV rays. This means little to no degradation or discolouration over their decades-long lifespan. As they are produced from plastic, these sheets are also far more flexible than bitumen or metal, which allows them to be used on roofs with more complex designs. What’s more, thanks to their clear finish, these sheets provide excellent light transmission, perfect for conservatories.

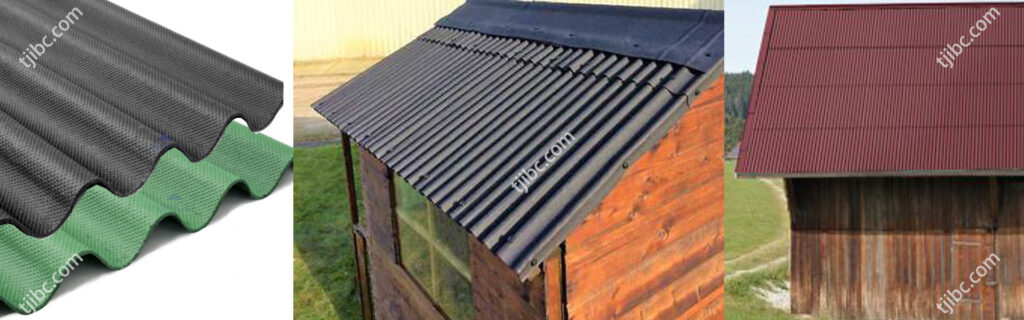

Bitumen

The third one is bitumen corrugated sheet. Corrugated bitumen roofing sheets are manufactured from fibres that have been saturated in bitumen (the same material they use to pave roads). This construction is what gives these sheets their high tensile strength at a light weight. Due to this, they are suitable for many different applications, including garages, sheds, summerhouses, carports, stables, shelters, and many other outbuildings. Created by leading brands Onduline and Coroline, these sheets are available in a wide selection of colours.

Fibre Cement

Fourthly is asphalt-coated fiberglass corrugated roofing sheets, we can also called fibre cement. It offers good resistance to fire and extreme temperatures, but may degrade in direct sunlight. Corrugated fibre cement roofing sheets are incredibly versatile, and offer a number of fantastic benefits over other materials. These sheets feature a reinforced composite construction, which makes them incredibly strong. What’s more, they’re immune to rust, rot, corrosion, and many other things which often plague roofing. Plus, fibre cement offers breathability, along with excellent thermal and acoustic insulation. This makes them perfect for both agricultural and industrial structures.

PVC

Finally, PVC corrugated roofing sheets are the lightest and cheapest option, but are also the least durable. PVC is similar in many ways to polycarbonate. Both materials offer a lightweight, shatterproof alternative to glass panelling, making it far safer. What’s more, corrugated plastic roofing are highly waterproof, and are cheaper than polycarbonate whilst also providing excellent levels of light transmission. The main drawback to PVC however, is its impact resistance. PVC is weaker than polycarbonate and may become damaged during severe weather. PVC roofing can also only be expected to last around 10 years.

Which Type of Corrugated Roofing Sheet is Best For You?

There are four main types of corrugated roofing: asphalt, metal, plastic, and fiberglass. Asphalt is the most common type of corrugated roofing and is made from a mixture of asphalt and aggregate. Metal roofs are made from either steel or aluminum and can be either painted or unpainted. Plastic roofs are made from PVC or acrylic and are available in a variety of colors. Fiberglass roofs are made from a fiberglass mat that is coated with resin.

Each type of corrugated roofing has its own benefits and drawbacks that you should consider before choosing the right one for your home or business. Asphalt roofs are durable and easy to install, but they can be susceptible to damage from sun and heat. Metal roofs are very durable and fire resistant, but they can be noisy during rainstorms. Plastic roofs are lightweight and easy to install, but they may not be as durable as other types of roofing. Fiberglass roofs are very strong and weather resistant, but they can be more expensive than other types of roofing.

Conclusion

There are quite a few different types of corrugated roofing sheet available on the market today. Each type has its own advantages and disadvantages, so it’s important to choose the right one for your needs. In this article, we have looked at seven of the most popular types of corrugated roofing sheet. We hope that this information will help you make an informed decision about which type is right for you.

So, what types of roofing sheets are available, and how do they compare to one another? The rule of thumb is that generally, a higher price means greater durability. Whilst costs can vary between brands, sheets made from each material will generally be in the same price range regardless of manufacturer. Another thing to note, is that almost all roofing sheets come in a corrugated profile, with the exception of tile effect and box profile sheets made from galvanised steel.

Related Products

Get In Touch With Us

IBC (Tianjin) Industrial Co.,Ltd manufacture and export all sizes of metal corrugated roofing sheet. And more information about “How to Install Corrugated Roofing Sheet” and what kinds of tool you will need when install the roofing sheet.

IBC Group supply not only metal corrugated roofing sheet, but also kinds materials roofing sheet. If you need more advices, please tell us, we will do our best for you!We do have factories to produce them with high quality and competitive price.