What is PPGL Coil Stand For?

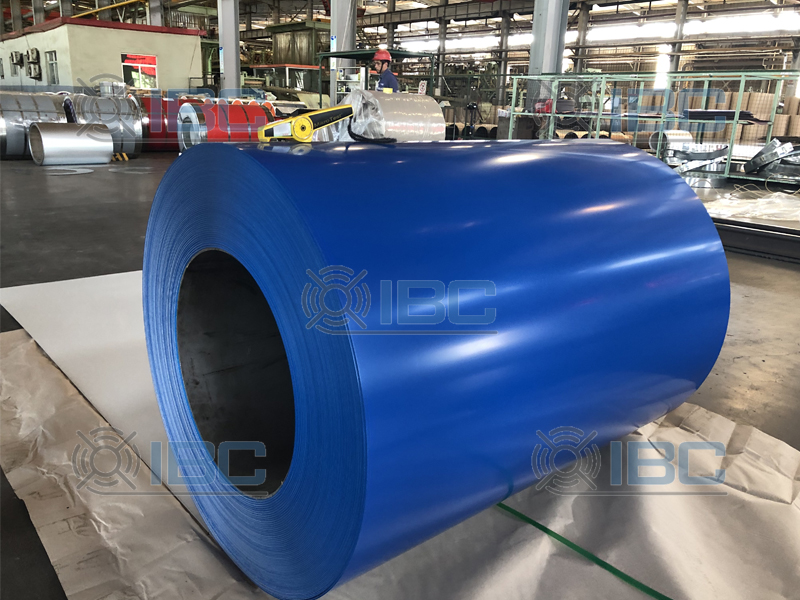

PPGL Coil standard for pre-painted galvalume steel coil. Also know as color coated steel. PP is short for pre-painted; GL is short for galvalume. So the full name of PPGL is PPGL is pre-painted galvalume.

PPGL specially designed steel sheets that employed in several furbishing and manufacturing purposes. Steel coils are thin sheets that rolled up into incessant coils. The galvalume coil employed outdoor, as it shows anti rusting tendencies. Most significantly, it used in constructing strong roofing system.

IBC (Tianjin) Industrial Co.,Ltd provide superior PPGL coils. Wide supply range of PPGL. We could provide all colors according to your needs. And costomized according to your sample, such as shiny or matte colors, pure colors or colorful ones. Just tell us what colors do you need in your projetcs.

Colors of PPGL for RAL

You can choose the customized color you want and produce according to the RAL color. Here are some of the colors that our customers would normally choose:

1013 RAL ; RAL 1015; RAL 2002; RAL 2005; RAL 3005;

3013 RAL; RAL 5010; RAL 5012; RAL 5015; RAL 5017;

RAL 6005; RAL 7011; 7021 RAL; RAL 7035; 8004 RAL;

RAL 8014; RAL 8017; 9002 RAL; RAL 9003; RAL 9006;

9010 RAL; 9011 RAL; RAL 9016; RAL 9017; and others.

The PPGL Coil is made by combining 55% Aluminum and Zinc Coated Steel Sheets. After coating the resulting product with organic substances, the product must then undergo a paint coating. It is this step that gives it the term ‘pre-painted’. For use in a variety of manufacturing industries spanning a wide range of sectors, PPGL Coils exhibit high levels of strength and dimensional accuracy. In addition to possessing high thermal conductivity and corrosion resistance, the finished raw material must also be corrosion-resistant.

The actual finished raw material must possess high thermal conductivity and resist corrosion in order to be suitable for use in various manufacturing industries covering a wide range of sectors. PGL Coils exhibit high levels of strength and dimensional accuracy. We provide the product that has a high quality finish and a long shelf life from our suppliers. Our product is usually dipped in hot liquid zinc to give it corrosion resistance. It can also be welded as per industry requirements.

Application of PPGL Coils?

In several manufacturing and furnishing applications, PPGL uses specially designed steel sheets. Galvalume coils are thin sheets that rolled up into incessant coils. They used outdoors for their anti-rust properties. Most importantly, it used to build strong roofing systems.

There are many kitchen appliances that require PPGL Coils for manufacture, including ovens, ranges, sinks, kitchen units, shelves, toilet strands, and cooker wrappers. This Coils also used in agriculture to make drying machines, farm equipment, greenhouses, silos, barns, and sheds. Vending machines, display cases, cans, bins, and signboards, as well as general everyday products, all need PPGL Coils to be prepared.

To equip the product with corrosion resistance, the finished product usually dipped in hot liquid zinc. It welded as per industry requirement. Our suppliers provide the product that has a high quality finish and a long shelf life.

Knowing what is PPGL coils and the applications of PPGL Coil, we could know how to use it. If you need more information, please contact with us!

Conclusions

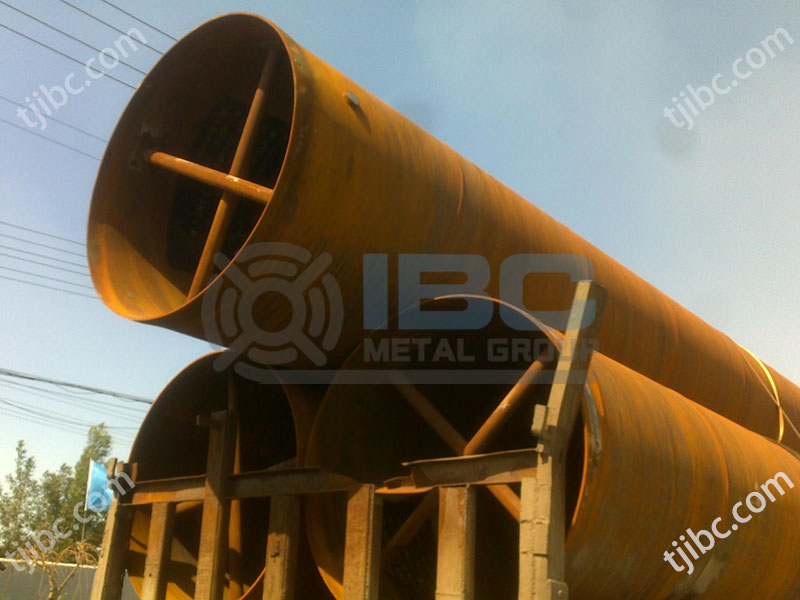

As well as galvanized steel coils, IBC Metal Group offer our customers a selection of galvalume steel coils in different sizes. Our galvanized steel coils include hot dipped, aluminum, and galvanized roofing sheets. Our steel sheets and coils are of the highest quality, ensuring customer satisfaction.