High Density Polyethylene (HDPE) Seamless Pipe suitable for the underground water supply and drainage in coal mines, downhole shotcrete, ventilation of positive negative pressure ventilation, waste residue of process water, backwater and long-distance underground pipelines for oil, water, and gas, etc. It include 3LPE/PP(2LPE)Coating. PE means polyethylene, PP means polypropylene.

High Density Polyethylene (HDPE) Seamless Pipe Coating Composition

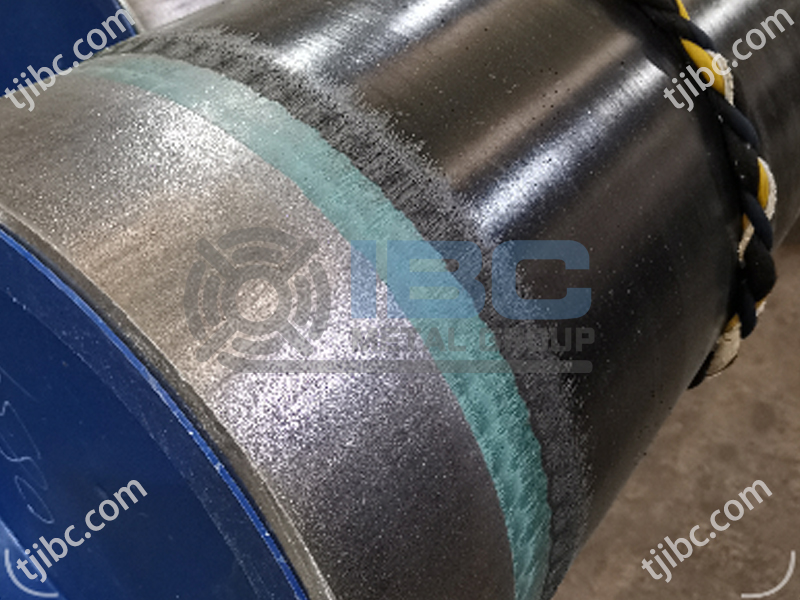

High Density Polyethylene Seamless Pipe totally has three layers. The first layer of coating is epoxy powder (FBE), the mid-layer is adhesive (AD). The top layer is high density polyethylene (PE)/ polypropylene (PP). The AD has high bonding property, anti-oxidation, and chemical corrosion resistance, excellent resistance to cathode stripping. And PE (PP) has the properties of moisture resistance, anti-aging, insulation resistance, and anti-mechanical shock. These combined integrated coating have characteristics of strong bonding strength, good insulation performance, mechanical shock resistance, long service life, small cathodic protection current density, and many other advantages. This coating widely applied in long-distance pipelines to convey water, oil and gas.

Raw materials of 3PE divided into both the normal operating temperature which is 60⁰C. And the high operating temperature type which is 80⁰C. 3PP coating operating temperature is -20⁰C~110⁰C. It widely used in severe and complex conditions. Because of its excellent UV resistance and a wide range of operating temperature.

Conclusions

We perform production in 3LPE/2LPE coating as per DIN30670. And NF A49-710, CAN/CSA Z245.21, ISO DIS21809-1, GB/T23257, SY/T0413. 3LPP/2LPP coating as per DIN30678, NF A49-711 etc. IBC Metal Group could supply all kinds of steel products for your projects. For more information, please contact with IBC’s experts today.

Contact with IBC Today!