High pressure boiler tubes belong to the category of seamless steel pipes, such as carbon steel ones, which need to hold a very high standard when it comes to their tightness. Though the manufacturing process is the same as any regular tube and many of the requirements are identical, those for high pressure boilers are stricter. This is due to its usage in extreme conditions of both heat and pressure, making ordinary pipes inadequate for operation. Consequently leading to the creation of special tubes specifically for high-pressure boilers.

High pressure boiler Seamless tube used for low and medium pressure boiler heating surface tube. Low and medium pressure means working pressure is generally not more than 5.88 MPa, working temperature below 450℃. It also used for high pressure boiler heating surface pipe, economizer, super-heater, re-heater, petrochemical industry pipe, etc. High pressure means working pressure generally above 9.8 MPa, working temperature between 450℃~650℃)

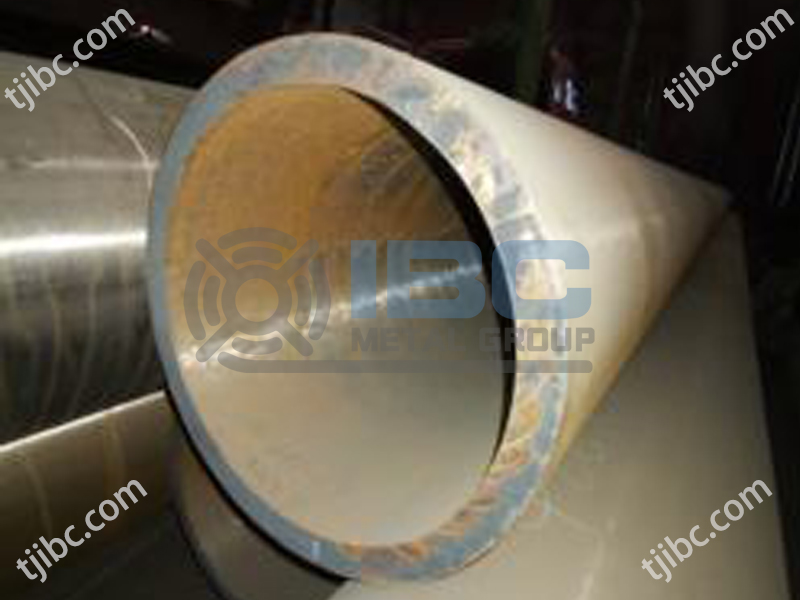

Seamless tube is a particular method of manufacturing tubes, however, the grade of steel used for its fabrication has strict specifications. Depending on the temperature range, it can be divided into standard boiler tube and high pressure boiler tube. The mechanical properties of these materials are a fundamental performance indicator. It is determined by the chemical content and heat treatment technique mentioned in the defined standards. In addition, a range of tensile strength yield strength or yield point elongation, hardness and toughness indicators as well as low and high temperature properties are regulated accordingly with the purpose they intend to fulfill.

Supply Range of High Pressure Boiler Seamless Tube

- Product Name: High Pressure Boiler Seamless Tube

- Standard: GB5310/6479; ASTM SA106/210; DIN17175; ASTM A213/335

- Grade: 20G, P265GH and etc.

- Length: 5.8m~12m

- Wall thickness: 20mm~70mm

- Shape: Round

- Technology: Hot Rolled

Applications

High-pressure boiler tubes have a wide array of applications. They are primarily used for making water-cooled wall tubes and steam tubes that have to bear extreme temperature. Moreover, they must be relied on for components subjected to extreme heat such as car engines. Plain pipes can’t resist the effects of superheated steam and liquid. High-pressure boiler tubes can also be utilized for creating ducts as well as airways in high-pressure and ultra-high-pressure boilers, which offer excellent heat and gas transfer properties. Furthermore, the hardness of the high-pressure boiler tube is quite strong – making it fit for use in industrial testing conditions.

Contact with IBC Metal Group Today!