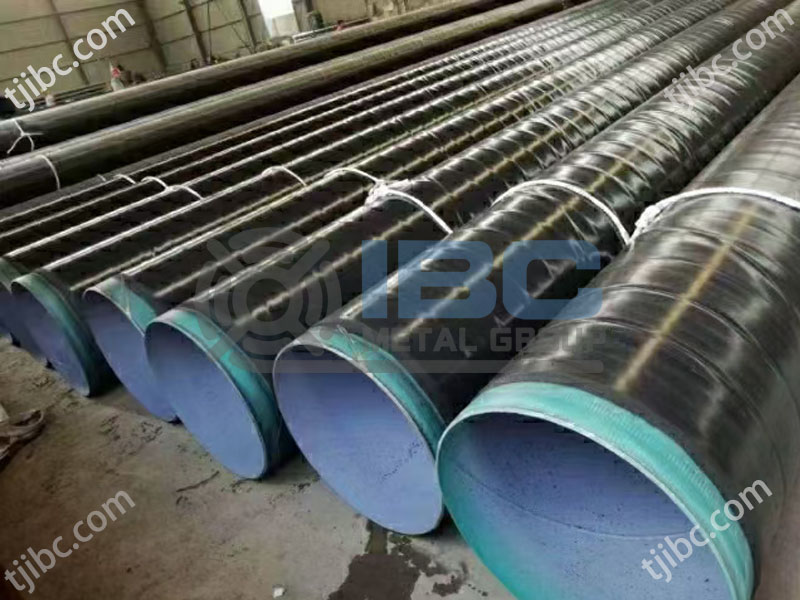

People usually ask: what is 3PE steel pipe? 3PE steel pipe we also called 3LPE steel pipe. It is 3-layer structure polyethylene coating anti-corrosion steel pipe. Its bottom layer is epoxy powder coating, the core layer copolymerized adhesive with branched functional groups. And the face layer is high-density polyethylene coating. The 3PE Coating Steel Pipe enjoys good impact resistance, abrasive resistance, shock resistance, acid resistance, high quality and long service life.

What is 3PE Steel Pipe Characteristic

3PE coated pipe is the most advanced technology for pipe anticorrosion. It combines the advantages of the 2PE coating pipe and the FBE coating pipe while avoiding their shortcomings. Each layer of the 3PE coated pipe has its own unique function within the coating structure.

The epoxy layer is the main source of anti-corrosion protection, providing a strong bond with the bare steel pipe and boasting favourable cathodic disbondment properties along with a broad temperature range (-40℃-100℃) and low water absorption. The adhesive layer serves to connect the epoxy layer to the PE layer and contains primarily polyolefin, which effects adhesion due to its polar functional groups forming hydrogen or chemical bonds with the FBE layer, as well as an affinity interaction with the PE layer through its non-polar ethylene component.

PE has excellent electrical insulation properties, low water absorption quality, and strong mechanical resistance. This layer’s primary function is mechanical protection and corrosion prevention. So 3PE coated pipe is a kind of composite system of these three layers with different functions, making the whole system with all the functions to better protect pipeline.

What is the Advantage of the 3PE Coating Steel Pipes

Under normal circumstances, a bare pipe will corrode in harsh environments and consequently have a shorter lifetime resulting in high construction and maintenance costs. However, due to the excellent performance of every single layer of the 3PE coating system, it can protect the pipe in rigorous environments and extend its life expectancy to as much as 30-50 years or more. This dramatically reduces the needed construction and upkeep expenses. Furthermore, with the 3PE coated pipe having an advantageous thermal insulation capability, thermal losses only 25% compared to traditional pipes which can save on energy costs when in use. Lastly, thanks to its impressive anti-corrosion properties and resistance against lower temperatures. The 3PE coated pipe laid directly underground or even in water without needing trenches to built first.

What is 3PE Steel Pipe Usage?

3PE coated pipes widely used in a variety of industries such as oil and gas, water transmission, heat transmission, mining, firefighting, thermal power plants, electric power plants, communication facilities and highways. They have superior characteristics which make them indispensible for underground coal mine water supply and drainage, underground spraying, ventilation (positive and negative), gas drainage, fire sprinkler networks etc. These pipes also employed in other applications such as thermal power plant process water waste and return conveying pipelines as well as cable protection sleeves for electricity and communications.

Furthermore they deployed in tap water engineering, gas transportation, buried water transportation or petroleum pipelines. In addition to this they used in chemical & pharmaceutical industries sewage treatment discharge pipes & sewage pipes plus biological pond anti-corrosion projects. Hence 3PE anti-corrosive steel pipes play an important role not only in agriculture with irrigation pipes and deep well pipes but also in the construction of drainage networks. With continual technological advances it expected that there will be even more potential for these types of steel pipes in the future.

Conclusion

3PE steel pipe is an anti-corrosion coating combining European 2PE and North American FBE. It widely used in many parts of the world over the last decade due to its superior impermeability and mechanical properties which come from epoxy resin and polyethylene materials. By combining these two layers, it produces a top-of-the-line effect and performance in corrosion prevention, making 3PE steel pipes highly sought after for a range of projects. IBC (Tianjin) Industrial Co., Ltd manufactures carbon steel pipes, alloy pipes, stainless steel pipes and more – please contact us if you have any questions.

Contact with IBC Metal Group Today!