Advantages of Aluminized Steel

Good anti-corrosion performance: the aluminum plating layer can effectively prevent the steel from contacting with the corrosive medium, forming a dense oxide film. It greatly improves the anti-corrosion performance of steel. This anti-corrosion property is an important reason why aluminized steel products are widely used in chemical, Marine, construction and other fields.

High temperature oxidation resistance: It has good high temperature oxidation resistance and can maintain stable performance at high temperatures for a long time. This characteristic makes this steel especially suitable for high temperature environments such as automotive exhaust systems and heat-resistant appliances.

Strong corrosion resistance: it can not only resist oxidative corrosion, but also resist the erosion of acid and alkali substances. This corrosion resistance allows it to better maintain surface finish and strength during use.

Long service life: Because this product has good corrosion resistance and corrosion resistance, its service life is relatively long. This is of great economic significance for occasions that require long-term use.

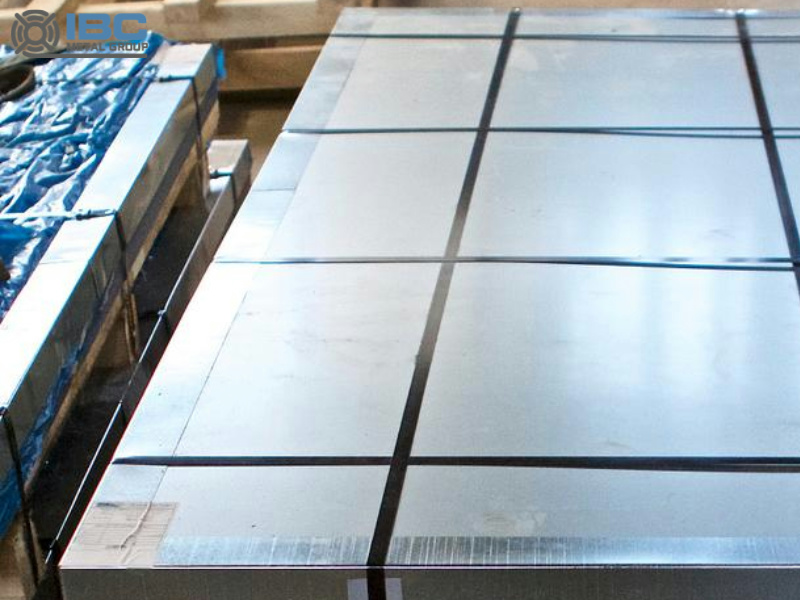

Good appearance: Its surface is smooth and beautiful, and it can maintain a good appearance. This kind of aesthetics makes it have a wide application prospect in the fields of architecture, decoration and so on.

Operation Process

Raw material ratio: The production of aluminized steel products needs to be prepared into paint and solvent in accordance with a certain proportion, and mixed evenly. This step is critical to the quality and performance of the product.

Steel strip pretreatment: Before coating, it is necessary to pretreat the steel strip, including degreasing, phosphating, reverse washing, micro-powder treatment and drying steps. These steps can ensure the cleanliness and flatness of the steel strip surface. And they can lay a good foundation for the subsequent coating process.

Coating: Feed the pre-treated steel strip into the coating line for coating. In this process, the uniformity of the coating and the thickness of the coating need to be controlled to ensure the quality and performance of the product.

Drying: After coating, it is necessary to dry the steel strip. The purpose of drying is to make the coating quickly evaporate water, so as to completely eliminate water, so that the coating bond fixed. The drying process requires control of temperature and time to ensure coating quality and surface finish.

Annealing: The steel strip after drying needs to be annealed. The purpose of annealing is to achieve an ideal magnetization state inside the coating and steel strip. And it is to correct for local oxidation that may occur after drying. The annealing process requires strict control of temperature, time and atmosphere.

Cutting, stacking, packaging: After annealing, the steel strip needs to be cut, stacking and packaging. When cutting, it is necessary to pay attention to ensure the size and flatness, and track and record each steel strip. Care should be taken to avoid collision and deformation when stacking and packing.

IBC Metal Group

Rich industry experience

With more than 10 years of export experience in the steel industry, IBC has an in-depth understanding of market needs. And it is able to respond quickly to customer needs.

High quality products

IBC’s steel products have been subjected to rigorous quality testing to meet ISO 9001/ ISO 14001 standards and have received CE certificates. In addition, IBC also accepts third-party inspections such as SGS and BV to ensure the stability and reliability of product quality.

Flexible order processing

IBC accepts orders of all sizes, whether it is a large volume purchase or a small amount of replenishment, and can meet customer needs in a short time. In addition, IBC has a large inventory and can respond quickly to market demand.

Optimized packaging and logistics

IBC adopts container packaging, which can significantly reduce production, storage, transportation and operation costs, and improve logistics efficiency. This packaging method also has the advantages of saving space, easy loading and unloading, and reduces the trouble of manual handling.

Contact with us today!