Structural Steel in Bridges

Structural steel widely used in bridges around the world, and in the United States alone, it accounts for over 30% of all bridges. Not only is steel strong, durable and flexible, but many of these structures impressive attractions which have earned awards or deemed architectural masterpieces. Steel bridges are not only functional but can be beautiful feats of engineering.

Using structural steel for large bridge projects ensures fast construction, creative designs, socio-economic advantages, and positive environmental effects. The wide range of constructible shapes this material offers has no limit; it molded into basic forms like arches and trapezoidal patterns or more complex shapes such as a serpentine torch or a knot. Its versatility even allows us to marvel at the modern steel structures we often see. It widely used in various types of bridges.

Beam Bridges

Designed with both function and efficiency in mind, this type is able to support reinforced concrete deck slabs using steel ‘I-beams’ resting on abutments or piers at each end. There are two distinct types of beam bridge: multi-girder ones that utilise multiple steel beams; and ladder decks, which use two steel beams along with intermediate bracings. Suitable for medium span highway bridges (13m to 100m), these structures have their decks rigidly connected to the connecting abutments so as to eliminate expansion joints and bearings. Simple in design, beam or stringer bridges do not strive for aesthetics.

Box Girder Bridges

Box girders, also known as ‘box bridges’, consist of two webs combined and supported by flanges at the top and bottom. These bridges are typically built using pre-stressed concrete, steel or a combination of both. They typically feature a hollow rectangular or trapezoidal shaped cross-section, which makes them ideal for applications requiring torsional stiffness like curved bridges. These types of bridges can span between 100 and 200m when utilizing one or multiple boxes. When used for lengths beyond this range, they usually form part of cable-stayed or suspension bridge designs.

Truss Bridges

The load-bearing ability of a truss bridge is determined by the configuration of its superstructure, which consists of interconnected steel elements organized in triangular sections. These sections permit the truss to respond to dynamic forces be it in tension, compression or both. Additionally, they can also serve as beams or components of composite decks, arch bridge stringers, cantilever beams or girders supporting cable-stayed bridges. Trusses have a variety of different applications including pedestrian bridges, demountable bridges, gantries and railway bridges with spans exceeding 50m.

Arch Bridges

A ‘through arch bridge’, also known as a ‘half-through arch bridge’ or ‘through-type arch bridge’, is an arch structure that supports the bridge deck. There are variations, like the tied-arch or bowstring arch bridge where the deck is hung from above in tension. These bridges are often constructed from steel trusses, plate boxes girder, steel I-beams or reinforced concrete sections and are suitable for spanning wide waterways or areas with difficult foundation works. Not only are they architecturally attractive but relatively cheaper and flexible too.

Suspension Bridges

Suspension bridges are commonly constructed by suspending two steel cables between two supports in the shape of a catenary. Short-span structures, such as footbridges, will often have this steel replaced with an arch steel pipe. High-tension wires then suspend the bridge deck from these cables across the length of the bridge. The tension forces are absorbed by the steel cables and hangers. These bridges are particularly suited to spanning longer distances; a prime example is the iconic Golden Gate Bridge in San Francisco, USA.

Cable-stayed Bridges

A cable-stayed bridge is an effective solution when spans are too long for a cantilever design, but not yet so far as to require a suspension bridge. In this kind of bridge, towers or pylons support the deck at intervals using high-tension cables. These secure the bridge in a fan-like pattern along the length of the deck and have made it possible to span distances of up to 1 km. The towers can come in A-frame, H-frame or column form, with the girders taking on compression and bending stresses under their weight.

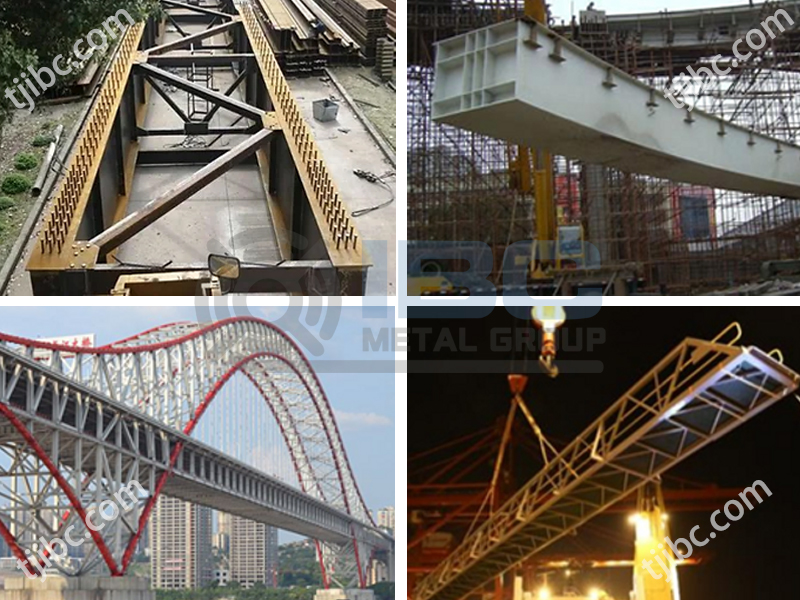

Heavy structural steel bridge products are supplied by IBC Group’s IBC Steel Structures division worldwide. In addition to completing major bridge projects around the world, IBC Metal Group is an expert in fabricating steel bridge girders and arches to international standards. IBC Metal Group’s policy is to fabricate and furnish clients with quality products to international standards.

The types of bridges within IBC’s capabilities include:

- Steel highway bridges

- Railway Bridges

- Movable Bridges – eg Bascule, Swing

- Heavy truss structures

- Multiple plate girders

- Trapezoidal box girders

- Suspension Bridges

- Steel Arch Bridges

- Temporary or Modular bridges

- Special Bridges

Other components that IBC Group can fabricate include:

- Handrails

- Steel columns

- Decking Formwork

- All types of bridge bearings

Should you have a requirement, you may contact our expert. Email us at sales@ibcmetalgroup.com

Contact with us today!