ERW pipe (Electric Resistance Welded) are manufactured by cold forming a flat sheet of steel into a cylindrical shape. Then current is passed between the two edges of the steel to heat the steel to a point at which the edges are forced together to form a bond without the use of welding filler material. Initially this manufacturing process used low frequency A.C. current to heat the edges. This low frequency process was not efficient and it was difficult to control.

Therefore, high frequency ERW (HFW) process came into existence. In HFW process, high frequency current is passed between the edges which melts the surface of the edges and forms a very strong weld zone without using any filler material. The HFW process provides superior weld integrity and flexibility compared to other methods available for joining steels.

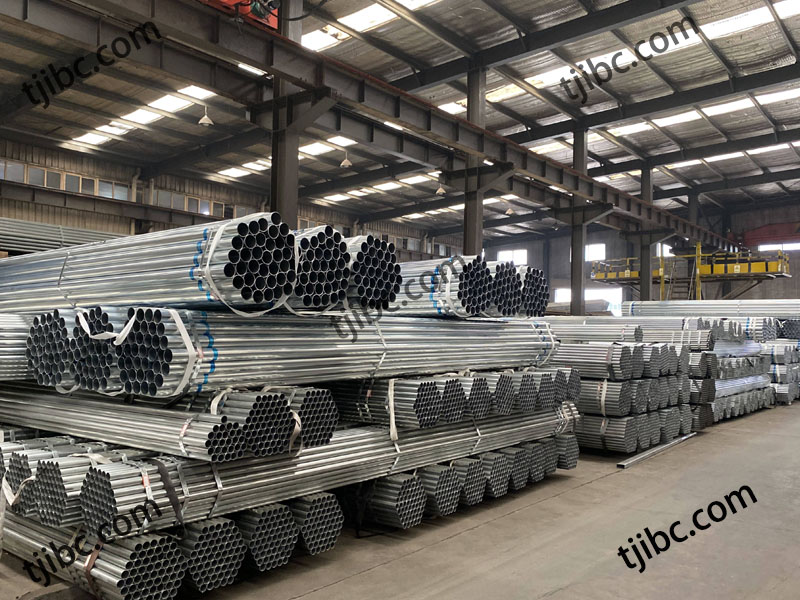

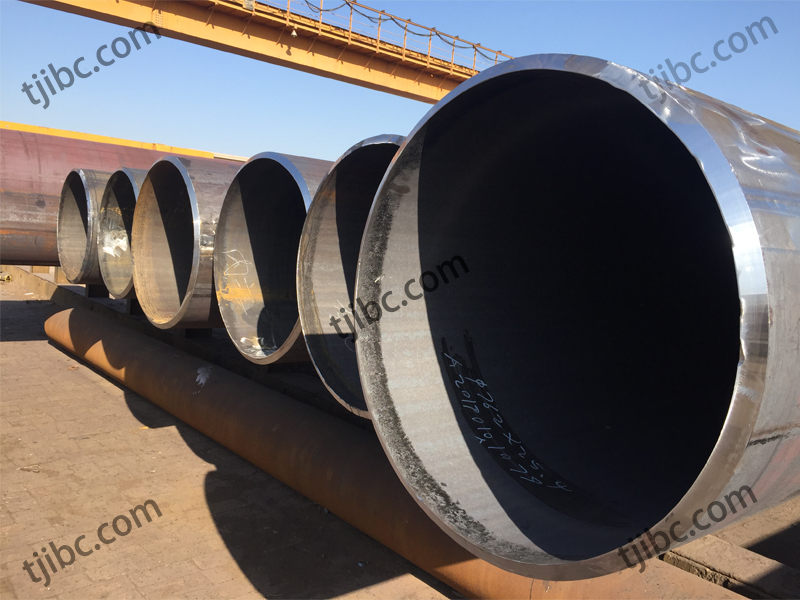

ERW Pipe Factory

Our entire manufacturing plant equipped with the latest machines which enable us to produce the high quality ERW steel pipes for our customers. As one of the reputed ERW steel pipe suppliers in China, all the industrial standards kept in mind while these steel pipes are being manufactured. After the manufacturing is done, all the steel pipes are sent to the quality testing department where their quality, strength, and performance are tested.

Specification of ERW Pipes

- Outside Diameter: 21.3 mm ~ 609.6 mm

- Outside Diameter: 1/2-inch ~ 24-inch

- Wall Thickness: 1.5mm ~ 16.0mm

- Length: 0.1M ~ 12M or Customized

Different Ends of ERW Pipe

There are four types of ends for ERW steel pipes. Plain end, beveled end, grooved end, and threaded end. Tell us which type you interested in?

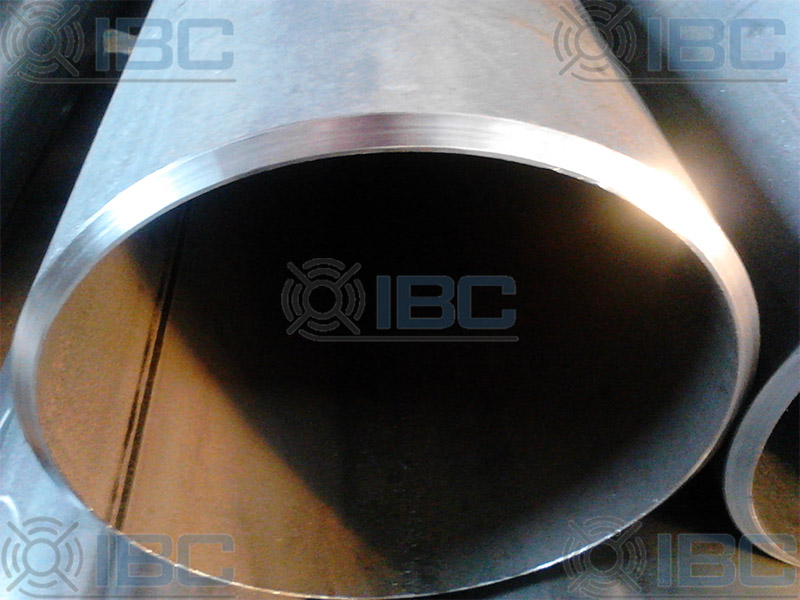

Plain End

Firstly, it is plain end which do not need exteral process after finish producing.

Beveled End

Secondly, beveled end.

Grooved End ERW Pipe

When pipe pretreatment performed, rolling grooved joints are used as pipe fittings. Its operating principle is the use of rolling groove rolling machine driven rotating pipe.

Threaded End

The best known and most widely used connection where the pipe thread provides both the mechanical joint and the hydraulic seal is the NPT. NPT has a tapered male and female thread which seals with tape or jointing compound.

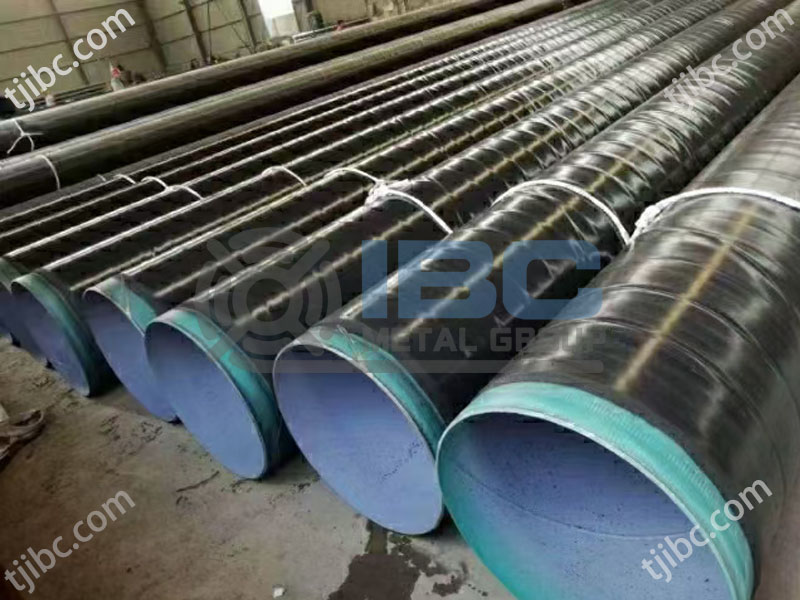

Different Coatings of ERW Pipe

Various steel pipe external coating projects currently implemented by our company including single-layer/double-layer FBE, 2PE 3PE,3PP and other anti-corrosion coatings with the performed standards such as DIN30670, DIN3067 1, DIN30678, CAN/CSA-Z24521-M92, SY/T4013-2002 and SY/T0315-97 etc.

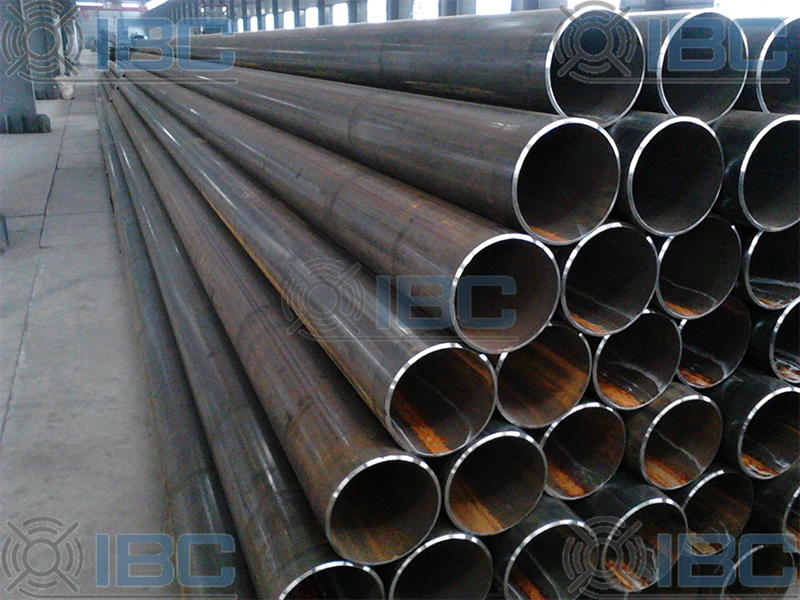

Black Coating ERW

Blue Coating ERW

Red Coating ERW Pipe

Applications of ERW Steel Pipe

ERW steel pipes are one of the most versatile and widely used pipe products on the market today. They have a wide range of applications, including in oil and gas, petrochemical, power generation, mining, water transmission, and more.

ERW steel pipes made from a variety of materials, including carbon steel, stainless steel, and alloy steels. They can manufacture to meet a wide range of specifications, including diameter, thickness, length, chemical composition, and more. ERW steel pipes commonly used in a variety of industries for a variety of applications. Some common uses include:

- Oil and Gas: ERW steel pipes often used in the oil and gas industry for pipeline transportation systems.

- Petrochemical: ERW steel pipes used in the transportation of crude oil and natural gas liquids.

- Power Generation: ERW steel pipes commonly used in power plants for steam lines and other piping systems.

- Mining: ERW steel pipes often used in mining operations for slurry transportation.

- Water Transmission: ERW steel pipes used to transport water over long distances.

There are many other potential applications for ERW steel pipes. If you have a need for a pipe product that can handle your specific application requirements, contact a reputable ERW pipe manufacturer to discuss your options.

Pipe Fittings For Fire Protection

Contact With Us!

Related Resources

SSAW Steel Pipe

LSAW Steel Pipe

Seamless Steel Pipe