What is A500 Structural Steel Pipe?

A500 Steel pipe (also known as ASTM A500). It specifies cold-formed, welded, and seamless carbon steel structural tubing in round, square, and rectangular shapes. It is the most common specification for hollow structural sections in North America. Since ASTM A500 is a structural specification, round pipe HSS produced to this specification is ideal for structural applications as well as general construction purposes.

Round A500 Structural Steel Pipe

Square A500 Structural Steel Pipe

Rectangular A500 Structural Steel Pipe

Galvanized Steel Pipe

No matter what kinds of A500 Structural Steel Pipe you need, please contact with us today!

Benefits of Structural Tubing

- Strength. HSS has a high strength-to-weight ratio, excellent compression support characteristics and excellent torsional resistance.

- Appearance. In exposed applications, especially Architecturally Exposed Structural Steel (AESS) applications in construction, HSS provides preferred visual opportunities for the design of buildings and other structures.

- Uniformity. HSS provides uniformity of size, shape, strength and tolerances that make its use totally predictable, especially important for demanding OEM applications.

- Easy of Fabrication. HSS can be readily bent, formed, punched and drilled. Improvements in connection design for fastening HSS to itself or other structural materials are improving the ease of fabrication in the field as well

- Cost Effectiveness. Due to its higher strength ratio, especially in A1085, HSS is cost competitive with other structural materials. With improved connection and fastening methods, it often enjoys a cost advantage.

- Resistance and Consistency. HSS is fire resistant and does not warp, twist, split, swell or shrink. And it resists dry rot and mildew.

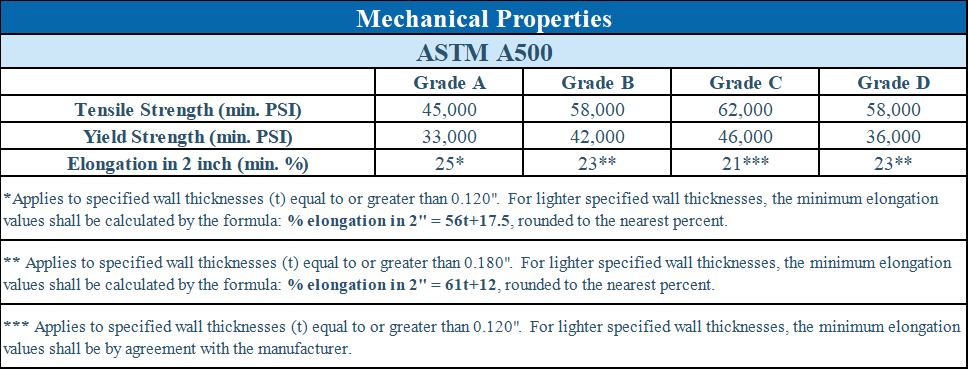

Mechanical Properties of A500 Structural Steel Pipe

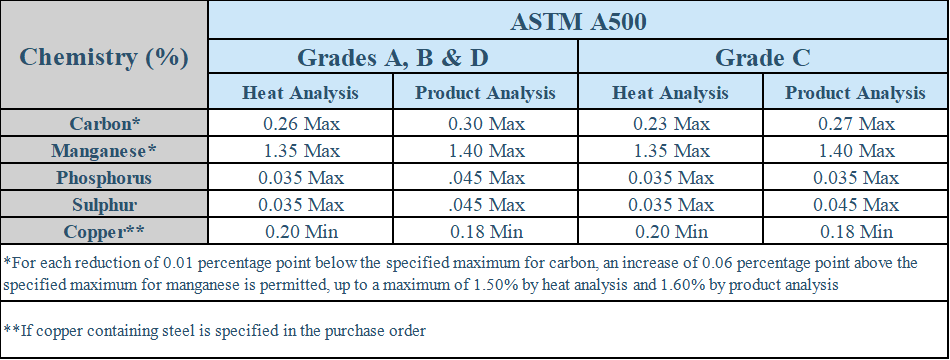

Typical Chemical Properties of A500 Structural Steel Pipe

What is the Difference Between Pipe A53 and A500?

How is ASTM A53 pipe different from A500 structure steel pipe? A500 pipe is typically used in structural applications and general construction. It should be used in buildings for curved columns, curved tube trusses, and curved steel frames. In mechanical and pressure applications, such as steam, water, and air lines, A53 pipe is typically used.

(1) Quality and Yield Strength

Yield strength should be taken into consideration when choosing materials, as A500 material will be stronger than A53 piping. A53 was once the go-to option for round shapes, but if used for columns or braces of a building, it would create thicker sections compared to what could be achieved with A500. In turn, this would require more steel by weight, therefore resulting in added costs. Fortunately, Grade B has been updated to Grade C which presents even higher yield strength (approximately 10% greater) at no extra cost. The member capacity tables set out in the forthcoming 15th Edition of the AISC Construction Manual will reflect this change. Taking all of these benefits into account serves as an excellent reason to opt for the highest quality tube available.

(2) Tolerances

As you see, A500 tolerances are tighter than A53 pipe tolerances. When you are selecting section sizes for your structural design, you will have more confidence that you will not only get the cross-sectional dimensions but also the necessary straightness with A500, as A500 producers must also adhere to a straightness tolerance specified in A500. With A53, there is no specification in the standard for how straight the pipe must be.

(3) Inside and Out

Thus far, we’ve focused on these two options’ structural characteristics, but what happens on the outside matters just as much. Because the A53 pipe is produced to carry pressurized steam, water or gas, the manufacturer must hydro-statically test their product, ensuring that it can withstand pressure when in use. If you are using A53 piping for structural applications, you can expect to pay for tests your application does not require.

Consider, too, that when you use an A53 pipe, you will pay in part for the sealant that producers use to coat the outside of the pipe. In order to weld to these pipes, a fabricator must remove the sealant you have paid for, an unnecessary cost and extra step in the fabrication process. The bare surface of the A500 tube makes it easier to paint, as well. Inside and out, the differences between A53 pipes and A500 tubing make clear: these two options are far from synonymous. For a host of structures—from building columns, braces, trusses, space frames and towers—A500 is clearly the appropriate choice.

A500 pipe is normally better for the majority of your structural steel construction projects because it has a higher yield strength than the A53 type pipe specification. This means that the strength-to-weight ratio is better than A53 grade pipe. A500 is not only stronger but also has better quality when used in curved structural steel applications.

Advantages and Disadvantages

A500 steel is easy to weld and machine, can be cold worked, and features a pleasing appearance. Specifically, A500 steel is similar to A53 in popularity and use, but it has a higher yield strength, is more corrosion resistant, and has a greater strength-to-weight ratio. As a result, it is more expensive than A53 grade steel.

Chemically and structurally, A500 better resembles A36 steel. The major difference between the two is in their use. Though both are hot rolled steel, A36 has many shapes and types, including rectangular bar, round bar, round tube, square bar, angle, channel, plate, tread plate, and shafting. A500 on the other hand is just used for metal pipes and tubes albeit these can be round, square, or rectangular.

A500’s primary advantage is its relative strength. Consequently, this steel grade works well for structural applications such as pipes, tanks, boilers, and heavy-duty equipment. The metal’s major disadvantage is its relative heat intolerance. It will shatter rather than shape at high temperatures.

Some structural steel fabrication drawings have material specifications that are probably incorrect. For example, many architects and engineers mistakenly detail their drawings calling for the use of pipe with an A53 vs. A500 grade specification in their bill of material.

Conclusion

Contact us for more information about A500 Structural carbon steel pipe. Or call us at and we will gladly discuss the specific requirements of your next project. IBC Metal Group’s pipe is your premium resource for advanced quality A 500 structural carbon steel tubing. We routinely stock both grades in standard lengths and can cut to any length in a variety of shapes.

Contact IBC!