ASTM A53 ERW Pipe manufacturered from IBC Metal Group are all in high quality and competitive price. It is a carbon steel pipe that comes under the ASTM A53 specification. ERW steel pipe in ASTM A53 Specification is one type called Type E. It is Electric Resistance Welded Steel Pipe. It Covers the two steel grades, Grade A and B. The pipes range in dimensions according to the ASTM, ASME and API standards. The sizes of the pipes range from 1/2-inches to 24-inches in nominal bore sizes.

Range of ASTM A53 ERW Steel pipe

- Type: ERW / Welded / Fabricated

- Specifications: ASTM A53, ASME SA53 A53 ERW pipe

- Dimensions: ASTM, ASME and API

- Size:Out Diameter:1/2″-24″

- Wall Thickness: 1.65-20mm

- Schedules: SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

- Length : 3-12m, or according to customer’s requirement

- End : Plain End, Beveled End, Treaded

Application of ASTM A53 GR.B ERW Steel Pipe

IBC Metal Group’s Products ASTM/ASME A53/SA53 seamless and welded steel pipe is a general, all-purpose pipe used in generator plants, refineries, compressor stations, natural gas transmission, and steam conduction. It is acceptable for welding, flanging, and bending. Firstly, architecture: maximum pipeline under more groundwater extraction when towers, boilers, hot water conveyance, etc. Secondly, machining, bearing sets, processing machinery and other accessories. Thirdly, electrical class: gas distribution, water power fluid conduit. And finally anti-static tubes wind power plants.

Expand information:

- ASTM A53 pipe comes in three types (F, E, S) and two grades (A, B).

- Type F is manufactured with a furnace butt weld or may have a continuous weld (Grade A only)

- E Type has an electric resistance weld (Grades A and B)

- A53 Type S is a seamless pipe and found in Grades A and B

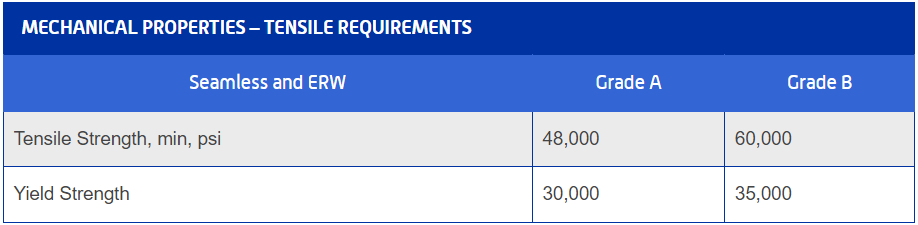

Mechanical Tests:

- Tensile Test: Two transverse tests required on the ERW for NPS 8 and larger, one across the weld and one opposite the weld.

- Flattening Test: On ERW for NPS 2 and larger, STD and XS wall (not required for XXS pipe)

- Bending Test (cold): For NPS 2 and under, XS wall and under; for NPS 1-1/4 and under, XXS wall

Testing Requirements for Seamless and Welded Pipe In ASTM A53

For plain end, threaded end and coupled pipe Hydrostatic Testing test pressures are specified. The pressure shall maintain for not less than 5 seconds for all sizes of seamless steel pipe and electric-resistance-weld pipe.

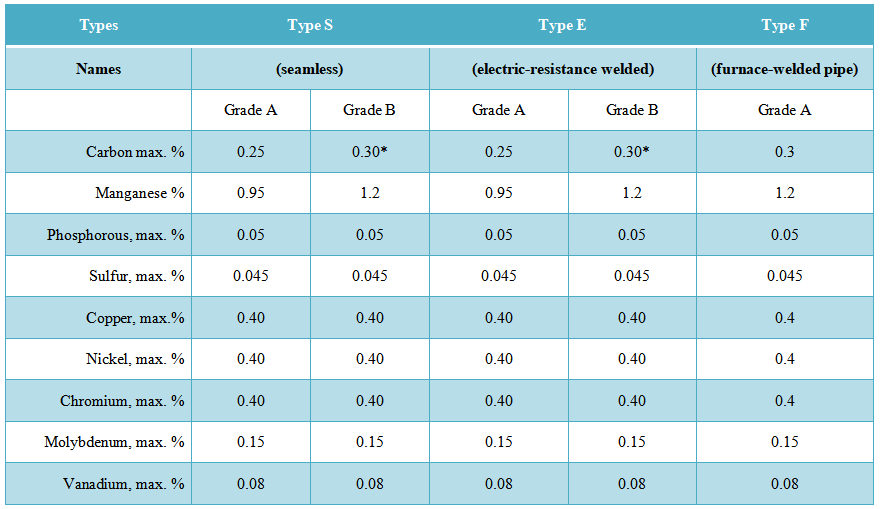

Chemical Composition For ASTM A53 ERW Steel Pipe

Weld Seam of ERW Steel Pipe

In ASTM A53 Specification, there requirement for the height of the weld burr of the electric resistance welded steel pipe (ERW pipe). The biggest difference between straight seam high frequency electric resistance welded pipe (referred to as ERW) and seamless steel pipe is that ERW has a weld, which is also the key to the quality of ERW steel pipe.

ERW Steel Pipe in Bundle

Usually, ERW steel pipe in small diameter, the smallest could be 1/2-inches. When shipping them, it should in bundle. Different sizes in one bundle have different pieces. Such as 37 pieces in one bundle in this shipping.

Our steel sourced, developed and produced from big steel factory which means our customers are assured of the highest quality standards and a local, concerned customer service presence invested in the success of your project. IBC Metal Group has control over every step of the pipe manufacturing process, from melt to final product. We manufacture our tubular products at several China-based facilities that produce high-quality tubular products with low-residuals in a wide range of strength levels with superior toughness.

Conclusion

IBC Metal Group provide all kinds of ASTM A53 Pipe (also referred to as ASME SA53 pipe). Including seamless pipe, ERW welded pipe, black and hot-dipped galvanized steel pipe. ASTM A53 pipe intended for mechanical and pressure applications and is also acceptable for ordinary uses in steam, water, gas and air lines. It is suitable for welding and for forming operations involving coiling, bending, and flanging, and other special purposes subject to certain qualifications.

Contact With IBC Metal Group