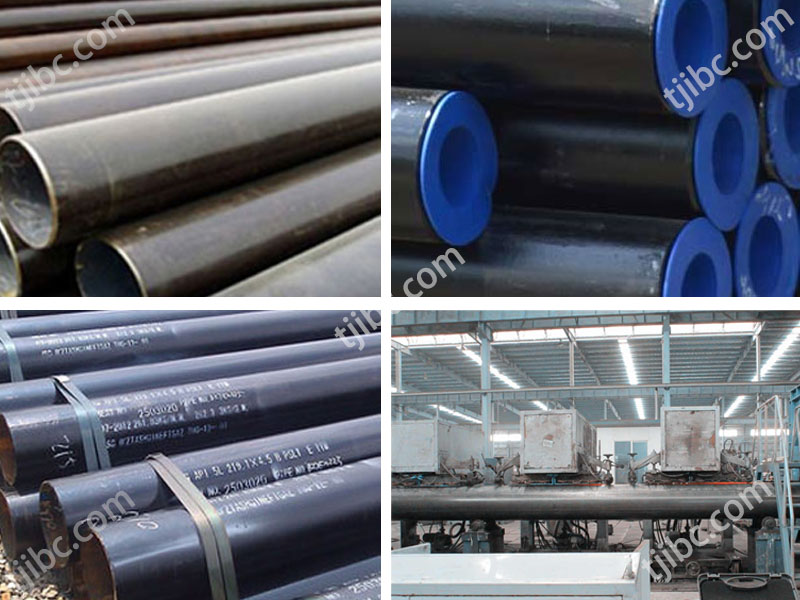

Brief Introduction of API-5L ERW Steel Pipe

This API 5L ERW steel pipe designed for oil and gas pipelines for various working environments. It generally made of carbon steel and meets API SPEC 5L specifications. It intended for petroleum and natural gas industries, oil industries requirements for transportation, and expected to work in extreme conditions, low and high temperatures, corrosion resistance in corrosion environments, and sour services in H2S environments.

Welded (ERW, LSAW, SSAW) Steel Line Pipe Grade Feature

- Common Class: API 5L Gr.B PSL1, PSL2, Sour Service pipe

- Medium: X42, X46; Medium: X52; Medium and high: X56

- High level: API 5L X60 PSL1, PSL2 LSAW line pipe

- High: API 5L X65 PSL1, PSL2 LSAW/SSAW line pipe

- Premium high: API 5L X70 / API 5L X80

- PSL2 pipe comes with suffix letter of N, Q, M, eg API 5L X52N, API 5L X60Q/M.

- Sour service pipe with suffix letter NS, QS, MS, eg API 5L X65QS.

API-5L ERW Steel Pipe Manufacturing Process

ERW process normally applied to the pipe below 24 in, 609 mm. ERW/HFW Longitudinally Welding Steel Line Pipe (Electric Resistance Welding ) Manufacturing Flow Chart.

Uncoiling – Flattening – Shearing and Butt Welding – Loop Storing – Plate UT – Trimming – Forming – High Frequency Welding – Removal of Inside and Outside Blurs – Ultrasonic Testing – Annealed by Medium Frequency – Air Cooling – Water Cooling – Sizing – Straightness – Cutting Off – Dimension and Initial Surface Inspection – Pipe Ends Beveling – Hydrostatic Test – Ultrasonic Testing of Entire Tube – Off Line Ultrasonic Testing – Ultrasonic Testing for Pipe Ends – Dimension and Final Surface Inspection – Corrosion Resistant Coating – Marking – Pipe Ends Protection – Inspection and Warehousing.

API 5L ERW Pipe produced under the American Petroleum Institute specifications. The pipes used in transporting petroleum products and other along a long line of pipes. Therefore the pipes have to be strong, corrosion resistant and wear resistant.

Specification of API-5L ERW Steel Pipe

Looking for specific thickness of API 5L Welded or Seamless Pipe? Wide stock of Schedule 40 to XXS API 5L Smls, Welded and ERW Carbon Steel Line Pipe in China.

OD Size Range:

- ERW: 0.375″ through 30″ ;

- HF: 0.840″ through 24″;

- DSAW/SAWL: 12.75″ through 144″;

- SMLS: 0.840″ through 26″;

- HSAW: 8.625″ through 144″.

Wall Thickness API 5L :

- ERW: 0.120″ through 1.000″;

- HF: 0.120″ through 1.000″;

- DSAW/SAWL: 0.250″ through 6.000″;

- SMLS: 0.250″ through 2.500″;

- HSAW: 0.250″ through 1.000″

Lengths:

Single Random | Double Random | Custom (up to 300′) & Required Length, Custom Size – 12 Meter lengths.

Surface Finishes:

Bare, Oiled, Mill Varnish, Galv, FBE, FBE Dual, 3LPE, 3LPP, Coal Tar, Concrete Coating and Tape Wrap. Various steel pipe external coating projects currently implemented by our company including single-layer/double-layer FBE, 2PE,3PE,3PP and other anti-corrosion coatings with the performed standards such as DIN30670, DIN30671,DIN30678,CAN/CSA-Z245.21-M92,SY/T4013-2002 and SY/T0315-97 etc.

End Finishes of API-5L ERW Steel Pipe:

Beveled, Square Cut, Threaded & Coupled. Specials Customize Sizes and Specifications also available as per customer’s specification in short time.

Additional Value Services:

Internal Coating | Galvanised Finish | Black Oil Paint | Heat Marked Pipes | Anti-Corrosion Oil, Galvanised Finish, Finish as per customer Requirements.

Specialized Products:

API 5L X42 Drill Pipe, API 5L X42 Petroleum Cracking Tube, API 5L X42 Seamless Steel Tubes for Liquid Service, API 5L X42 Tube for Structural Purposes, API 5L PSL 2 X42 Seamless Carbon Steel, API 5L X42 Line Pipe.

Inspection, Test Reports:

Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports, India Boiler Regulations (IBR) Test Certificate, Mill TC EN 10204 3.1, Lab Test Reports, Flatten test, Impact test, Tensile test, Yield Test, Ex-Stock, Hydro test, UT test, DWT test if agreed etc.

Form of API-5L ERW Steel Pipe:

Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes.

API-5L ERW Steel Pipe Pipe Packing:

API 5L Pipe Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests.

Conclusion

The API 5L pipe is widely used in oil and gas refineries, nuclear and thermal power generation systems, pressure vessels, boiler equipment, petrochemicals, sugar industries, etc. Our goal is to produce top-quality products, which will be available at feasible rates for all. We have the stock of leading API 5L Pipe manufacturers in India.

Contact with us!