What is Pressure Vessel Steel Plate? At IBC Group, we design pressure vessel steel plates with thicknesses ranging from 14 gauge up to 2″. Pressure vessel steel plate is a range of material grades designed specifically for use in pressure vessels containing gases or liquids at high pressure. We use welding equipment and techniques, which according to ASME’s Sect 9 & AWS D1.1, D1.6 specification.

Inspection pressure vessel steel plates, usually under standard such as ISO, TUV, the American Bureau of Shipping (ABS), and The National Board of Boiler and Pressure Vessel Inspectors. We also employ a full time certified welding inspector to qualify our welders, weld processes, and provide in process inspection. So our manufacturing and welding processes meet and exceed the requirements of these standards.

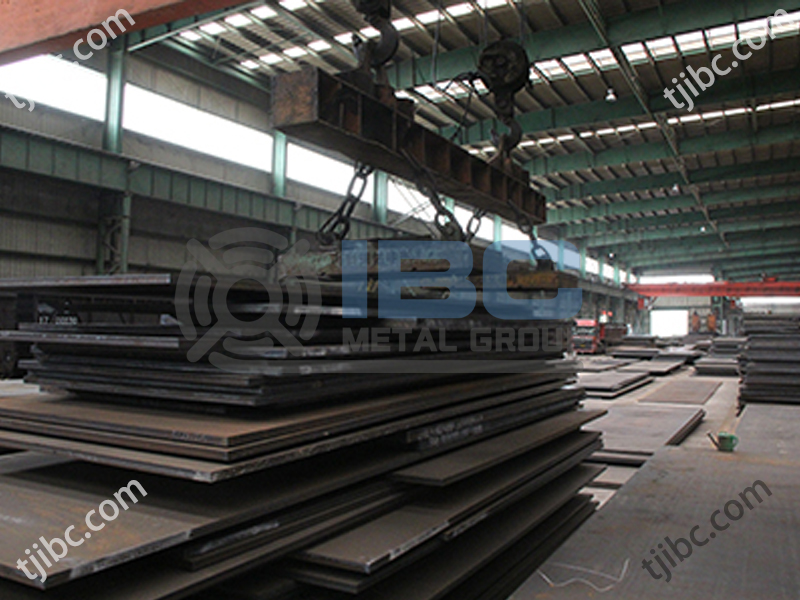

More About Pressure Vessel Steel Plate

Steel and metal plates are common materials when manufacturing pressure vessels. The quality of the plate makes a huge difference to the performance and durability of the vessel. We utilize materials of the highest quality to manufacture pressure vessels. Here, we discuss the importance of the quality of metal plating in pressure vessels.

Pressure vessel plate covers a range of steel grades. designing for use in pressure vessel, boilers, heat exchangers and any other vessel that contains a gas or liquid at high pressures. Familiar examples include gas cylinders for cooking and for welding, oxygen cylinders for diving. And many of the large metallic tanks that you see in an oil refinery or chemical plant.

There is a huge range of different chemicals and liquid that that stored and processed under pressure. These range from relatively benign substances such as milk and palm oil to crude oil and natural gas and their distillates to highly lethal acids and chemicals such as methyl isocyanate.

So of these processes need the gas or liquid to be very hot, whilst others contain it at very low temperatures. As a result there is a wide variety of different pressure vessel steel grades that meet the different use cases.

In general. we can divid them into three groups. There is a group of carbon steel pressure vessel grades. These are standard steels and can cope with many applications where there is low corrosion and low heat. As heat and corrosion have more effect on the steel plates chromium, molybdenum and nickel. We add them to provide additional resistance.

Pressure Vessel Steel Plate Applications

- Pressure vessel steel plate, used for many applications where the pressure inside is significantly higher than atmospheric pressure.

- A516 steel plate is carbon steel with specifications for pressure vessel plates and moderate or lower temperature service.

- A537, heat-treated and as a consequence, displays greater yield and tensile strength than the more standard A516 grades.

- A612, used for moderate and lower temperature pressure vessel applications.

- A285 steel plates, intended for fusion-welded pressure vessels and plates are typically supplied in the as-rolled conditions.

- TC128-grade B has been normalized and used in pressurized railroad tank cars.

Pressure Vessel Steel

We manufacturer & supply a wide range of pressure vessel steel plate grades for working environments where safe operating pressure is critical. Our pressure vessel steel is of Western European origin. Which is the steel of choice for the world’s boiler & pressure vessel fabricators.

IBC Group have a global reputation for the supply of high quality pressure vessel steel to these fabricators. And many of them are suppliers to some of the worlds largest gas, oil and petrochemical companies.

Applications of Pressure Vessel Steel Plate

Pressure vessel and boiler quality steel are commonly found throughout the oil industry (including inshore and offshore), the petrochemical industry and the gas production industry.

The companies in these industries set the highest demands in terms of quality, testing and conditions of supply, and we have all the necessary expertise to meet these demands. In recognition of the increasing need for pressure vessel steel plate to demonstrate HIC Resistant properties. It is also available ex–stock.

This plate is particularly suited for pressure equipment where wet H2S corrosion can be a problem. Quality is key when it comes to designing and manufacturing industrial pressure vessels. With industrial grade pressure vessel steel plates, IBC Group can manufacture robust and long-lasting pressure vessels of various types.

The manufacture of pressure vessels is tightly regulated as a result of the risks involved. And as a consequence the materials that can be using in vessels is also tightly specified. The most common specifications for pressure vessel steels are the EN10028 standards. Which are European in origin – and the the ASME/ASTM standards which are from the US.

Conclusion

Our strength is in the very high specification pressure vessel steel plate used in the oil and gas industry. And specifically in steel plate resistant to Hydrogen Induced Cracking (HIC) where we have one of the largest stocks worldwide. Contact with IBC (Tianjin) Industrial Co.,Ltd today to get more details.

Contact with IBC Group Today!