ASME SA353 Pressure Vessel Plates Factory

IBC (Tianjin) Industrial Co., Ltd manufacture ASME SA353 Pressure Vessel Plates for decade years. Including other specifications, such as DIN, EN, JIS, ASTM/ASME standard, etc. ASME SA353 specification covers 9% nickel steel plates that double-normalized and tempered, and this steel used for cryogenic welded pressure vessels. These steel plates usually limited to a thickness of 50 mm.

Cryogenic gases such as argon, nitrogen, and oxygen can be contained and transported at temperatures below -195°C with ASTM A353 9% nickel. ASTM A353 9% nickel steel plate has a tensile strength of 690-825 MPa and a yield strength of 515 MPa. These properties make it ideal for cryogenic pressure vessel steel production.

Supply Range of ASME SA353 Pressure Vessel Plates

- Standard: ASME SA353/SA353M

- Steel Grade : SA353

- Thickness :1.5mm -260mm

- Width :1000mm-4000mm

- Length :1000mm-18000mm

- MOQ: 1 PC

- Product type : Steel plate

- Delivery time : 10-40 days (Production)

- MTC: Available

- Payment Term : T/T or L/C At sight .

Scope of ASME SA353 Pressure Vessel Plates

This specification covers 9% nickel steel plates, double-normalized and tempered, intended particularly for welded pressure vessels for cryogenic service. Plates produced under this specification are subject to impact testing at −320°F [−195°C] or at such other temperatures as are agreed upon.

Plates have an upper bound on thickness of 2 in. [50 mm] determined by its capacity for meeting the necessary mechanical properties. Magnetic materials should kept away from magnets after heat treatment to avoid any residual magnetism which could affect subsequent fabrication or use. Standards for both inch-pound units and SI units recognised, with the latter appearing in brackets within the text. However values between the systems are not equal and thus should not combined – failure to do so may lead to a mismatch of requirements.

General Requirements and Ordering Information

This material must comply with the standards of SpecificationA 20/A 20M, which covers testing and retesting methods, acceptable sizes and weight, repairs of damages, branding, loading, etc. Furthermore, when buying for this specification, customers should make sure that the ordering details are in line with the aforementioned rules. Supplementary terms may also be imposed if particular control or tests are needed to meet particular applications; these include: vacuum treatment, additional tension tests, impact tests and non-destructive examinations.

The purchaser is referred to the listed supplementary requirements in this specification. And to the detailed requirements in Specification A 20/A 20M. If the requirements of this specification are in conflict with the requirements of Specification A 20/A 20M. The requirements of this specification shall prevail.

Heat Treatment

Plates, heads, and reinforcing pads should undergo heat treatment in accordance with the following procedure. First, they should be heated to a uniform temperature of 1650 ± 25°F [900 ± 15°C], held at that temperature for a minimum of 1 h/in. [2.4 min/mm] of thickness (but no less than 15 minutes), and cooled in air. Afterward, they should be reheated to a uniform temperature of 1450 ± 25°F [790 ±15°C], held at that temperature for a minimum of 1 h/in. 2.4 min/mm of thickness (but no less than 15 minutes), and cooled again in air.

Reheat the plate to a temperature between 1050 to 1125°F [565 to 605°C] uniformly and hold it between those temperatures for a minimum of 1 h/in. 2.4 min/mm of thickness, with no less than 15 min allowed. Cooling should be done in air or water quench at 300°F/h [165°C/h] or faster rate. If hot forming is done after heating to 1650 to 1750°F [900 to 955°C], the first normalizing treatment (5.2.1) can be omitted. It will be the responsibility of the fabricator who heat treats the plates to apply the necessary heat treatment and conduct tests they deem necessary, so that the specified properties are achieved.

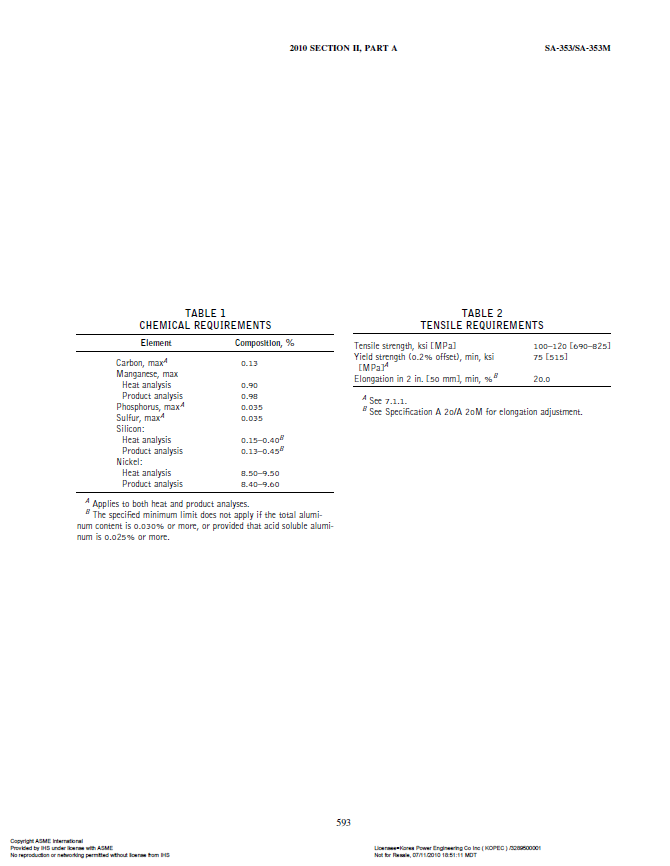

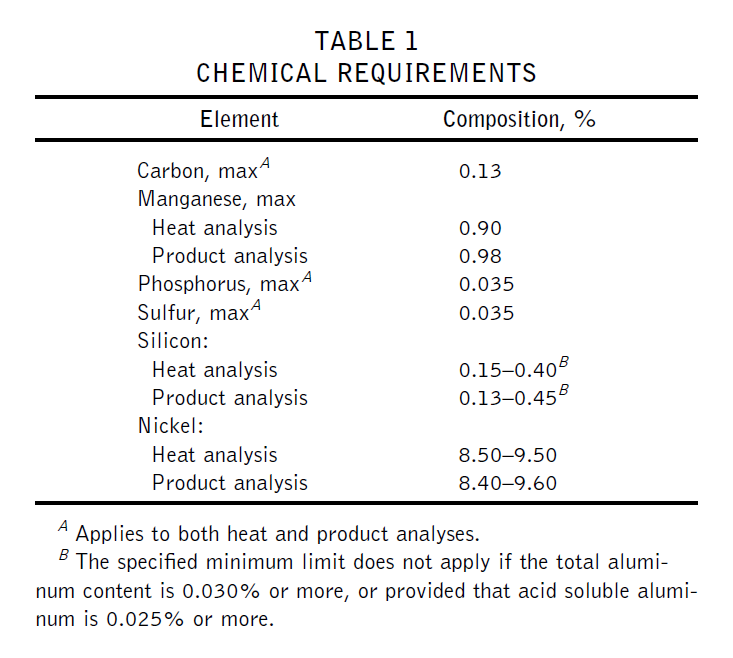

Chemical Requirements of ASME SA353 Pressure Vessel Plates

The steel shall conform to the chemical composition requirements shown in Table 1. Unless otherwise modified in accordance with Supplementary Requirement S17, Vacuum Carbon-Deoxidized Steel, in Specification A 20/A 20M.

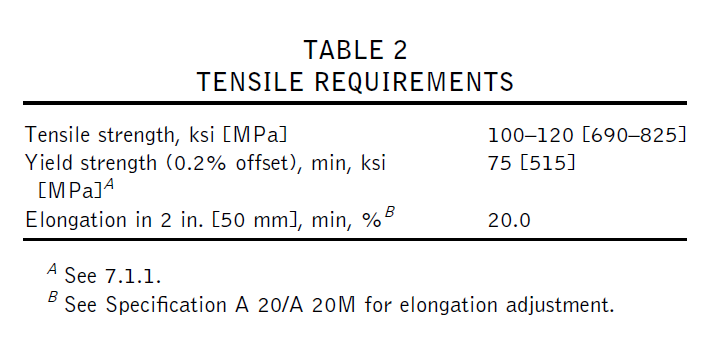

Mechanical Requirements of ASME SA353 Pressure Vessel Plates

Tension Test Requirements—The material as represented by the tension-test specimens shall conform to the requirements specified in Table 2.

Upon agreement between the purchaser and the manufacturer, yield strength determined by the extension under load method, using 0.005 in./in. [0.005 mm/mm] total extension. For nominal plate thicknesses of 3/4 in. [20 mm] and under, the 11⁄2 in. [40 mm] wide rectangular specimen used for the tension test and the elongation determined in a 2 in. [50 mm] gage length that includes the fracture and shows the greatest elongation. One tension test taken from each plate as heat treated.

Impact Test Requirements: Charpy V-notch impact tests made in accordance with Specification A 20/A 20M. The longitudinal axis of the test specimens shall be transverse to the final rolling direction of the plate. Unless otherwise agreed, tests shall be conducted at −320°F [−195°C]. Each test specimen shall have a lateral expansion opposite the notch of not less than 0.015 in. [0.381 mm].

Because retained scale may mask surface imperfections. As well as mar the plate surface, plates descaled by the producer after heat treatment. In the case of material to be heat-treated by the purchaser, the plates descaled by the producer prior to shipment.

What’s the Difference Between ASTM A353 and ASME SA353 ?

In fact, the mechanical and chemical properties of the steels are identical. And it is the producer of the standard that is the key difference. ASTM, the American Society for Testing and Materials, produces standards that define limits and parameters on a product’s properties and the methods of testing those properties.

ASME, the American Society of Mechanical Engineers, specifies materials to use in the manufacture and construction of particular items. The relevance of this to pressure vessels is that ASME publishes design codes and standards for the manufacture of vessels and within these a particular material standard endorsed. ASME “acquires” ASTM specifications in this way. And its pressure vessel code committee assigns an “S” to the relevant ASTM standard. So A353 becomes SA353 when ASME acquires it.

Conclusion

As one of the leading suppliers and manufacturers of carbon steel plates in China. IBC Metal Group supply and manufacture low-temperature 9% Ni steel plates and equivalent materials. According to A353 and ASTM A553 in various sizes and specifications. If you are looking for this material, please contact us or get a quotation. Not only do we have all kinds of sizes. But we also have all kinds of sizes that are hard to find.

Contact with us today!

Related Products

Related Resources

ASME SA353 Specification