ASTM SA553 Pressure Vessel Plates Type 1covers 9% nickel alloy steel plates that used in the fabrication of cryogenic pressure vessels. This material is capable of operating at temperatures as low as -196oC, and has high levels of strength and weldability.

We produce ASME SA553 Pressure Vessel Plates for decade years. IBC (Tianjin) Industrial Co., Ltd supply and export all sizes & thickness & standards pressure vessel steel plates to all over the world. Such Canada, South America, Europe, Africa, as well as Asia, etc. Contact with IBC for more information.

Scope of ASME SA553 Pressure Vessel Plates

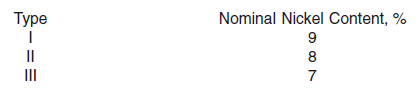

This specification covers 7, 8, and 9 % nickel alloy steel plates for use in the water quenched and tempered condition intended for the fabrication of welded pressure vessels. Material under this specification is available in three types having different chemical composition as follows:

Plates produced under this specification are subject to impact testing at −320°F [−195°C] for Type I or Type III, and −275°F [−170°C] for Type II; or at such other temperatures as are agreed upon.

The maximum thickness of plates is limited only by the capacity of the material to meet the specified mechanical property requirements; however, current mill practice normally limits this material to 2 in. [50 mm] max. This material is susceptible to magnetization. Use of magnets in handling after heat treatment avoided. if residual magnetism would be detrimental to subsequent fabrication or service.

The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units shown in brackets. The values stated in each system not exact equivalents; therefore, each system used independently of the other. Combining values from the two systems may result in non-conformance with the specification.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Requirements and Ordering Information

3.1 Material supplied to this material specification shall conform to Specification A20/A20M. These requirements outline the testing and retesting methods and procedures, permitted variations in dimensions. And mass, quality and repair of defects, marking, loading, and ordering information.

3.2 In addition to the basic requirements of this specification, certain supplementary requirements are available when additional control, testing. Or examination required to meet end use requirements. The purchaser referred to the listed supplementary requirements in this specification and to the detailed requirements in Specification A20/A20M.

3.3 If the requirements of this specification are in conflict with the requirements of Specification A20/A20M. The requirements of this specification shall prevail.

Heat Treatment

5.1 All plates shall be heat treated in accordance with 5.2. Shell plates and other parts, including heads and reinforcing pads. Which heated for forming, shall be heat treated after forming in accordance with 5.2.

5.2 Heat Treatment Procedure

—Heat treat all plates by heating to a suitable temperature within the range from 1475 to 1700°F [800 to 925°C], holding for a sufficient time to obtain uniform temperature throughout the plate thickness and then quenching in water. Subsequently, temper the plates within the range from 1050 to 1175°F [565 to 635°C] for Type I and Type II, or from 1000 to 1125°F [540 to 615°C] for Type III, holding at this temperature for a minimum of 30 min/in. [1.2 min/mm] of thickness but not less than 15 min, and cool in air or water quench at a rate not less than 300°F/h [165°C/h].

5.2.1 Hardening

—The plates shall be heated to a temperature within the range from 1475 to 1700°F [800 to 925°C], held at that temperature for a sufficient time to obtain uniform temperature throughout the plate thickness, and then quenched in a liquid media.

5.2.2 Tempering of ASME SA553 Pressure Vessel Plates

—The plates shall be tempered at a temperature within the range from 1050 to 1175°F [565 to 635°C] for Type I and Type II, or from 1000 to 1125°F [540 to 615°C] for Type III; being held at that temperature for a minimum of 30 min/in. [1.2 min/mm] of thickness, but in no case less than 15 min, and then cooled in air or liquid-quenched at a rate not less than 300°F/h [165°C/h].

5.2.2.1 Prior to the tempering treatment, the plates may be subjected to an intermediate heat treatment consisting of heating to a temperature in the range from 1165 to 1290°F [630 to 700°C] for Type I, or 1185 to 1310°F [640 to 710°C] for type II, or 1205 to 1330°F [650 to 720°C] for Type III; holding at that temperature for a suitable time, but in no case less than 15 min, and then water-quenching to below 300°F [150°C] in the case of plate thicknesses of more than 5⁄8 in. [16 mm] or cooling in air or water-quenching to below 300°F [150°C] in the case of plate thicknesses of 5⁄8 in. [16 mm] and under.

NOTE 1

—The intermediate heat treatment is for the purpose of enhancing elongation. And notch-toughness and for reducing susceptibility to strain-aging embrittlement and temper embrittlement. It may performe at the option of the material manufacturer or may be specified by the purchaser.

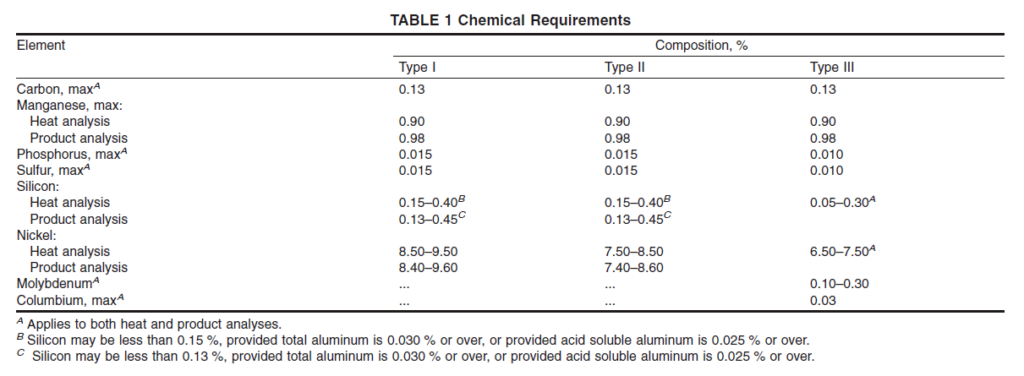

Chemical Requirements of ASME SA553 Pressure Vessel Plates

The steel shall conform to the chemical requirements shown in Table 1 unless otherwise modified in accordance with Supplementary Requirement S17. Vacuum Carbon-Deoxidized Steel, in Specification A20/A20M.

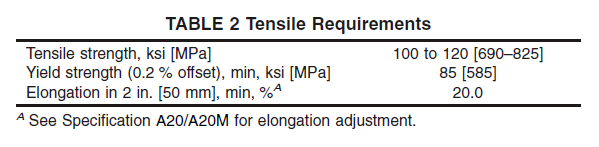

Mechanical Requirements of ASME SA553 Pressure Vessel Plates

Tension Test Requirements—The material as represented by tension-test specimens shall conform to the requirements specified in Table 2.

Finish

Because retained scale may mask surface imperfections. As well as mar the plate surface, plates shall descale by the producer after heat treatment. In the case of material to be heat-treated by the purchaser. The plates shall be descaled by the producer prior to shipment.

Marking

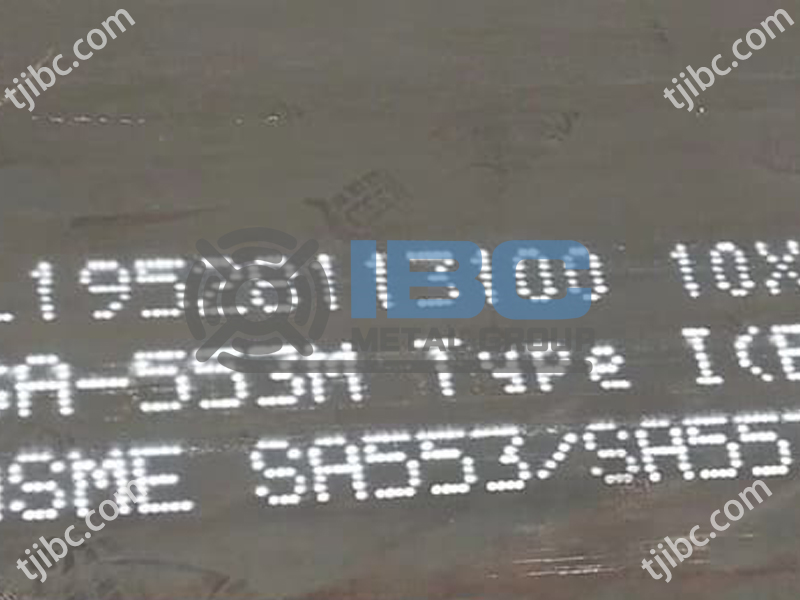

in addition to the marking required in Specification A20/A20M. Each plate legibly stamped or stenciled, depending upon the ordered thickness. With the letters QT, except as otherwise specified in 9.1.1. 9.1.1 When the optional heat treatment in 5.2.2.1 performed. The plates shall marke with the letters QTT instead of QT.

Conclusion

IBC Metal Group manufacture & export all kinds of Pressure Vessel Steel Plates. Such as ASME SA203, ASME SA204, ASME SA285, ASME SA299, ASME SA302, ASME SA353, ASME SA387, ASME SA515, ASME SA516, ASME SA517, ASME SA537, ASME SA553, ASME SA612, ASME SA662, and JIS G3103, JIS 3115, DIN, EN, etc. With high quality & competitive price, our products popular all over the world. IBC Group will provide our value quotation for you. We committed to integrate steel resources in China and serve the global steel market. IBC have decade years of experience in steel researching, production, managing and sales. Our ability to purchase materials directly from leading mills will give you the competitive edge. For more information or you need any of pressure vessel plates in your projects, please contact with us today.

Conact with ibc today!