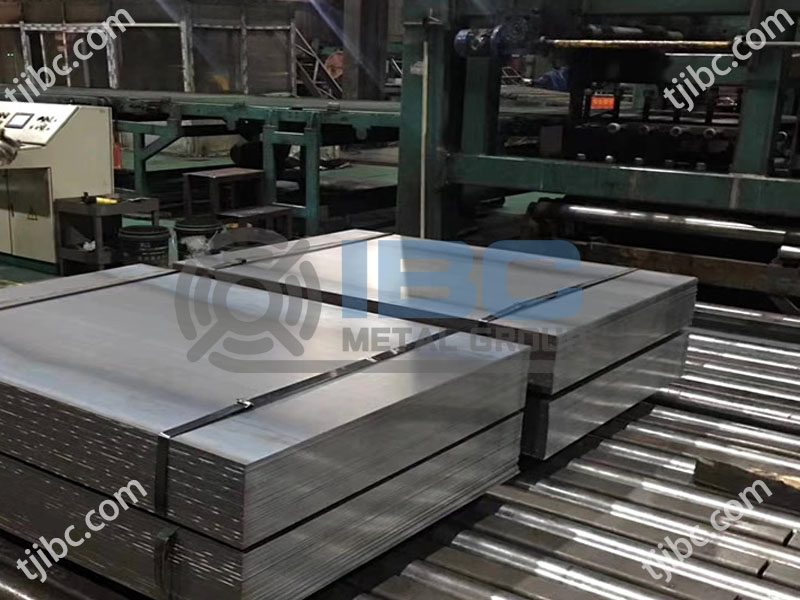

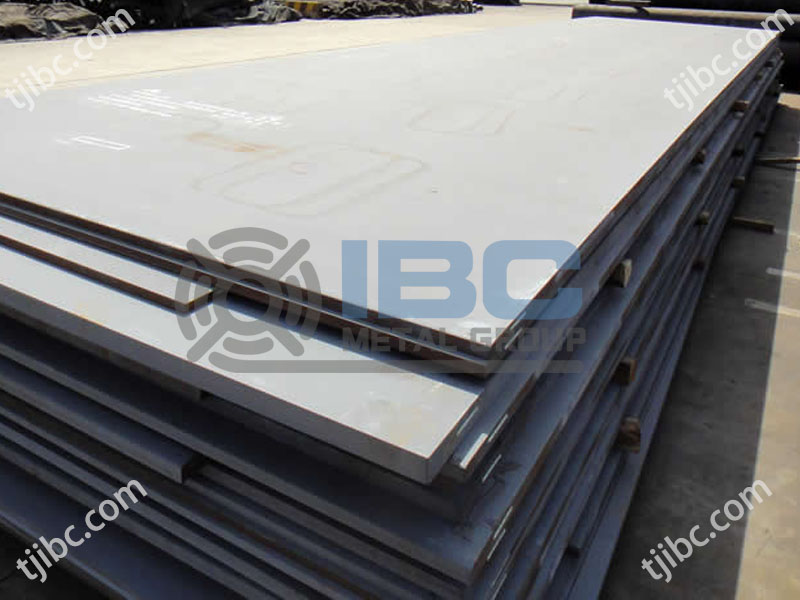

ASME SA302 Pressure Vessel Plates Manufacturer

IBC Metal Group offer cheap price with good quality ASME SA302 Pressure Vessel Plate under ASME SA302 standard, which is a specification for Pressure Vessel Plates, Alloy Steel, Manganese – Molybdenum – Nickel, as well as Manganese – Molybdenum – Nickel. Our company has been supplying pressure vessel steel plates for many years. We do all kinds of Pressure Vessel Plates. For more informations, or need quotation for your projects, please contact with us today!

Scope of Specification ASME SA302

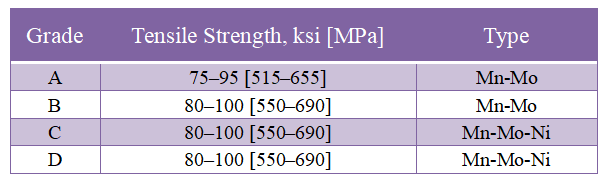

This specification covers manganese-molybdenum and manganese-molybdenum-nickel alloy steel plates intended particularly for welded boilers and other pressure vessels. Plates under this specification are available in four grades having different strength levels as follows:

The maximum plate thickness determined by the chemical composition being able to meet the necessary mechanical requirements, and the minimum is 0.25 inches (6.5 mm). Both inch-pound and SI units have been designated as standard; the SI units are shown within brackets in the text. It should note that these two systems do not have an exact equivalence, so using both simultaneously may lead to a failure of this specification.

General Requirements and Ordering

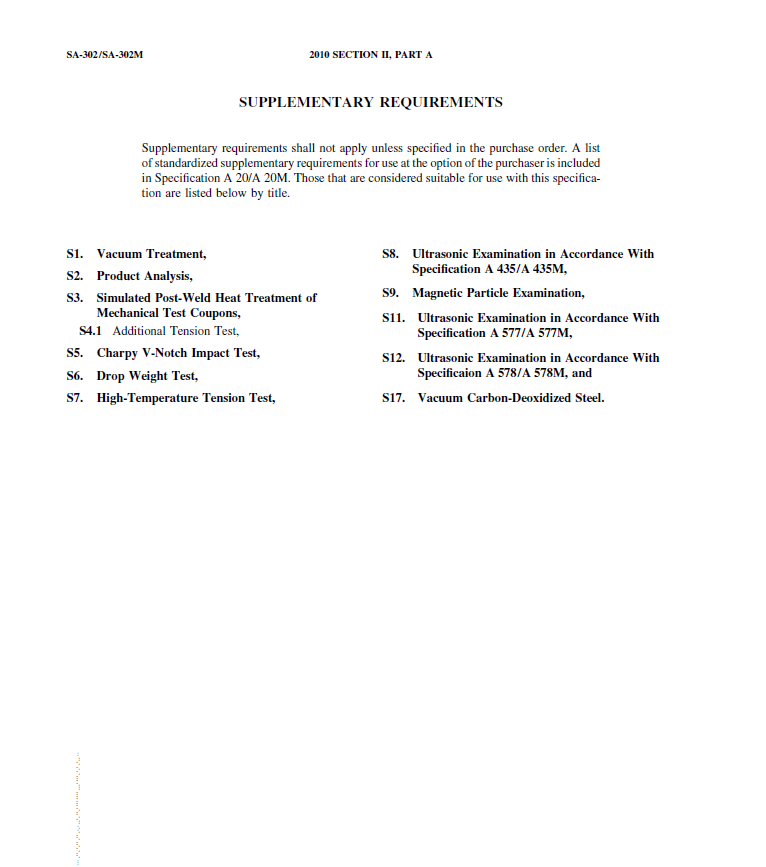

Plates supplied in accordance to this product specification are subject to Specification A 20/A 20M, which outlines dimensions, mass and quality requirements, as well as the tests and processes used to examine and repair defects. It also sets out rules for ordering information when purchasing. In addition, supplementary requirements exist to further guarantee the end use needs of the product. The purchaser referred to the listed supplementary requirements in this specification and to the detailed requirements in Specification A 20/A 20M.

Coils are not eligible for this specification until they’re transformed into finished plates. This transformation entails cutting the coil into individual lengths, testing, inspection and conditioning. For some goods, heating may also required. Afterwards, packaging, branding, loading and certification must take place before shipment allowed. The processor is in charge of this entire process.

NOTE 1— For plates produced from coil and furnished without heat treatment or with stress relieving only, three test results reported for each qualifying coil. Additional requirements regarding plates from coil described in Specification A 20/A 20M. If the requirements of this specification are in conflict with the requirements of Specification A 20/A 20M, the requirements of this specification shall prevail.

Heat Treatment

Plates 2-in. [50 mm] and under in thickness are normally supplied in the as-rolled condition. We ordered plates normalized or stress relieved, or both.

Plates over 2 in. [50 mm] in thickness shall be normalized. When normalizing plates 4 in. [100 mm] or over in thickness, the cooling rate may be accelerated by air blasting or liquid quenching to obtain mechanical properties comparable to those developed by normalizing plates in the lesser thicknesses.

If approved by the purchaser, for plates less than 4 in. [100 mm] in thickness, cooling rates faster than those obtained by cooling in air are permissible for improvement of toughness, provided the plates are subsequently tempered in the temperature range from 1100 to 1300°F [595 to 705°C].

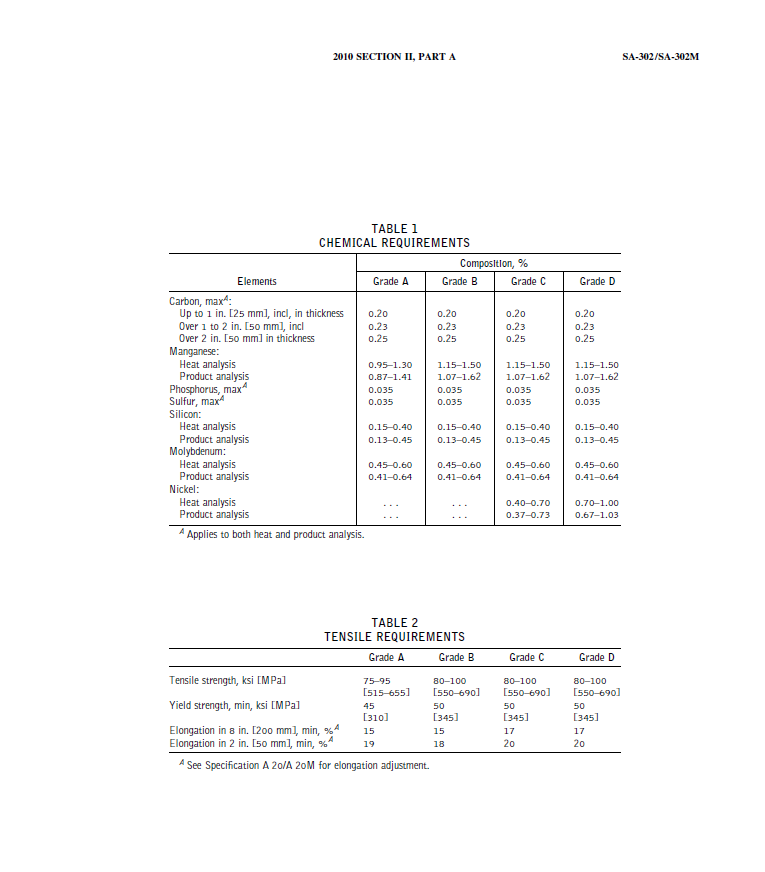

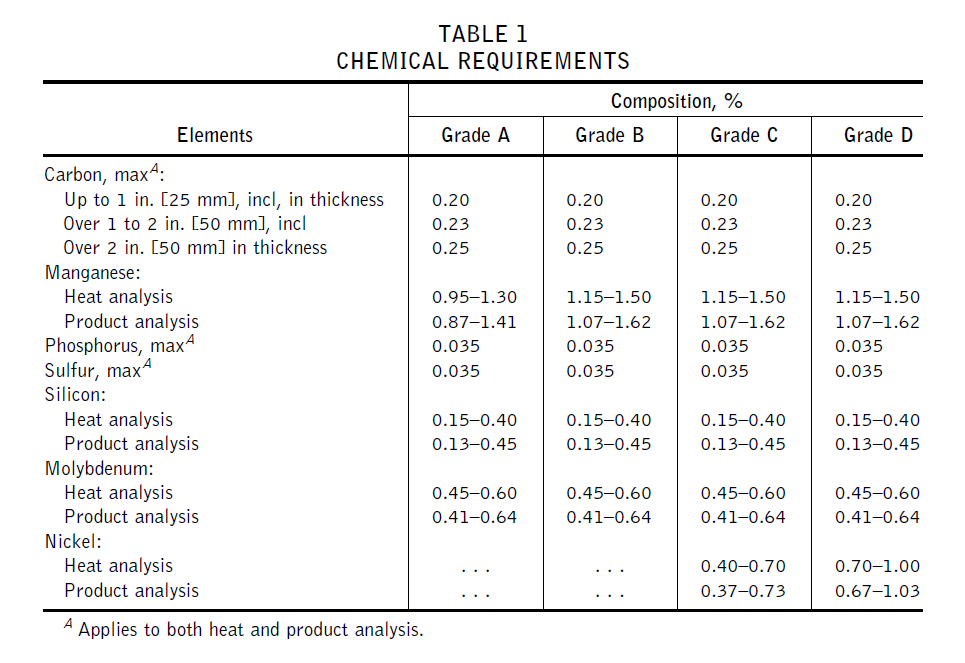

Chemical Composition

The steel shall conform to the chemical requirements shown in Table 1 unless otherwise modified in accordance with Supplementary Requirement S17, Vacuum Carbon-Deoxidized Steel, in Specification A 20/A 20M.

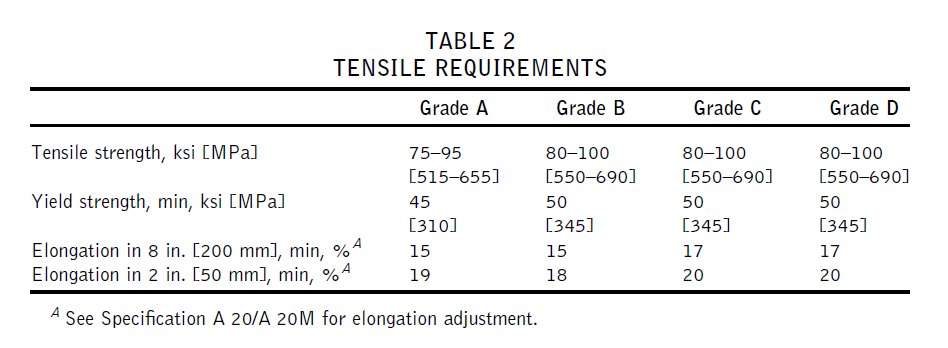

Mechanical Properties

Tension Test Requirements — The plates as represented by the tension test specimens shall conform to the requirements given in Table 2.

For accelerated cooled plates with a nominal thickness of 3⁄4 in. [20 mm] or less, the 11⁄2 in. [40 mm] wide rectangular specimen may be used for the tension test, and the elongation may be determined in a 2 in. [50 mm] gage length that includes the fracture and that shows the greatest elongation.

Application

Mn-Mo And Mn-Mo-Ni Alloy Steel Plates for Pressure Vessels ASME SA302 is widely used in the petroleum, chemical, power plant, boiler industries. It is used in the manufacturing of reactors, heat interchangers, separators, spherical tanks, holders for oil and gas, liquefies the boilers, nuclear reactor pressure shells, boiler steam drums, liquefied stone oil vapor bottles, high pressure water pipes, equipment, and water shell components.

Technical Requirements & Additional Services for SA302 Steel Plate:

- High tension test

- Low temperature impacting test

- Normalised for thick plates over 40mm

- Simulated post-welded heat treatment (PWHT)

- Rolling under standard NACE MR-0175 (HIC+SSCC)

- Issued Orginal Mill test certificate under EN 10204 FORMAT 3.1/3.2

- Shot blasting and Painting,Cutting and welding as per end user’s demands

Why Choose Us?

- Best Quality-Steel plate from China First-Class mill with Die stamp include heat number and batch number, It cantrack.

- Fast Delivery-Good relationship with Mill and Forwarder Shipping Agent for producing and shipping.

- Professional Team-Work steel business more than six years for export steel plate.

- Reasonable Price-Cooperate with 15 mills, satisfy with different request for the price and quality.

- Kinds of Payment-T/T, L/C at sight, Usance Letter of Credit.

IBC (Tianjin) Industrial Co., Ltd supply SA302 pressure vessel steel plate, mainly used in construction for welded boilers and other pressure vessels. SA302 Grade B steel plate normally supplied in the as-rolled condition. Plates ordered normalized or stress relieved, or both. If A 302 Grade B above 50mm in thickness normalized. We also offer cutting and welding services in processing plants. Get an valued quotation for SA302 Grade B Boiler steel plate, Now, contact IBC Metal Group.

Contact with us today!

Related Products

Related Resources

Specification of ASME SA302 Pressure Vessel Plates