ASTM A672 ERW Pipes outlines the requirements for electric fusion welded steel pipe for high pressure service in moderate temperatures. Heat treatments may be necessary to obtain desired properties or to meet code regulations. An analysis of the plate material and finished deposited weld material from every 500 feet (or fraction thereof) shall be done. The mechanical tests required include one tension test specimen per lot of finished pipe and two transverse-guided-weld-bend tests per lot of pipe. Radio-graphic examination of the full length of each weld must also carry out.

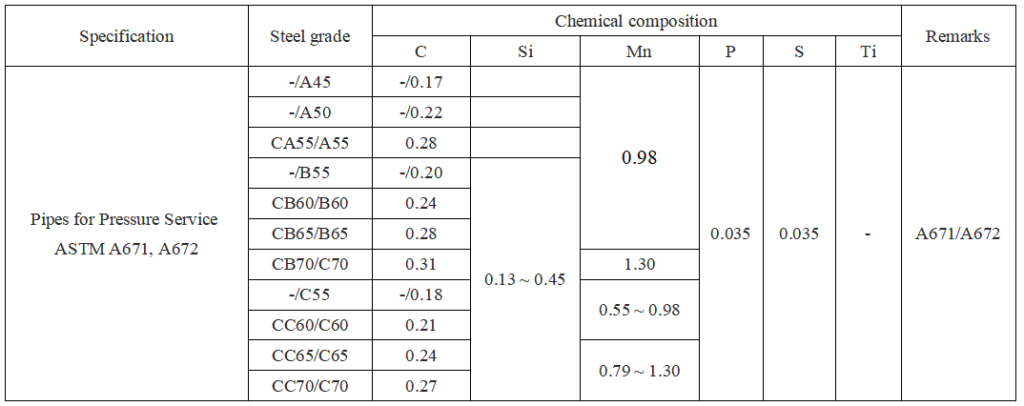

Chemical Requirements of ASTM A672 ERW Pipes

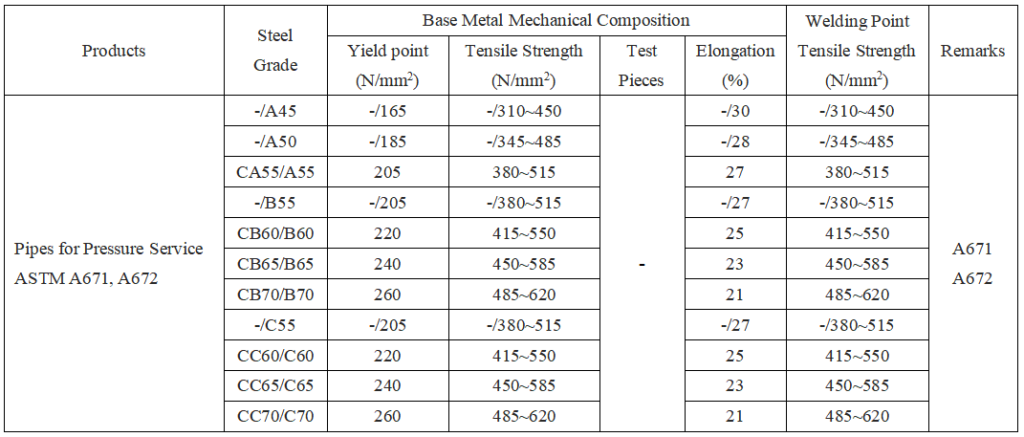

Mechanical Properties of ASTM A672 ERW Tubes

A672 pipes used in speciality chemicals, chemical equipment, petrochemicals, condensers, heat exchangers, gas processing, pharmaceuticals, sea water equipment, offshore oil drilling companies, pulp and paper companies, among other industries. In addition to hot rolling and heat expansion, ASTM A672 B70 can also be cold drawn.

The ASTM A672 and its equivalent pipes renowned for their mechanical properties such as durability and toughness. Further, they boast a high resistance to corrosion which is augmented when treated with surface coatings like black or coloured oil paint and anti-corrosion oil. Moreover, hot and cold galvanization of the ASTM A672 pipe produces extra protection from atmospheric wear and tear. When necessitated, heat treatment can also apply to the ASTM A672 material pipe as per the consumer’s request.

At IBC Metal Group, we have an extensive selection of ASTM A672 Pipe products to meet the piping needs for multiple industries like water, petroleum, oil & gas. ASTM A672 EFW Pipe Carbon Steel Pipes used in both structural and fluid transmissions. We provide these pipes in various grades and classes (A672 B60, A672 B65, A672 B70 Class 12, 22, 32) to suit any given application. Each class characterized by its own individual testing methods.

Contact with us today!