In addition to welded steel pipes, seamless steel pipes can also be manufactured using hot rolling and cold rolling. Seamless steel pipes have no seams, as their name suggests, and made through hot rolling and cold rolling. In contrast, welded pipes manufactured by rolling a steel coil to the required gauge thickness, a manufacturing process that leaves a seam in the pipe’s surface. The next step is to cut the seams to the desired size based on the pipe’s size.

Electric Resistance Welded (ERW), Spiral Submerged Arc-Welding Pipe (SSAW), and Longitudinal Submerged Arc-Welding Pipe are three different forms of welded steel pipe (LSAW). These three types of welded steel pipe manufactured in significantly different ways.

Most of the world’s steel production used in construction, from bridges to buildings. This allows for tall and strong structures since steel is able to bear the weight of these constructions. When it comes to choosing specific types of pipes that fit a particular project, like bridge foundations, architects and contractors have to take into consideration various environmental conditions, such as earthquakes, ship collisions or strong currents. In those scenarios, is there any difference between having seamless or welded pipes? Let us study the differences.

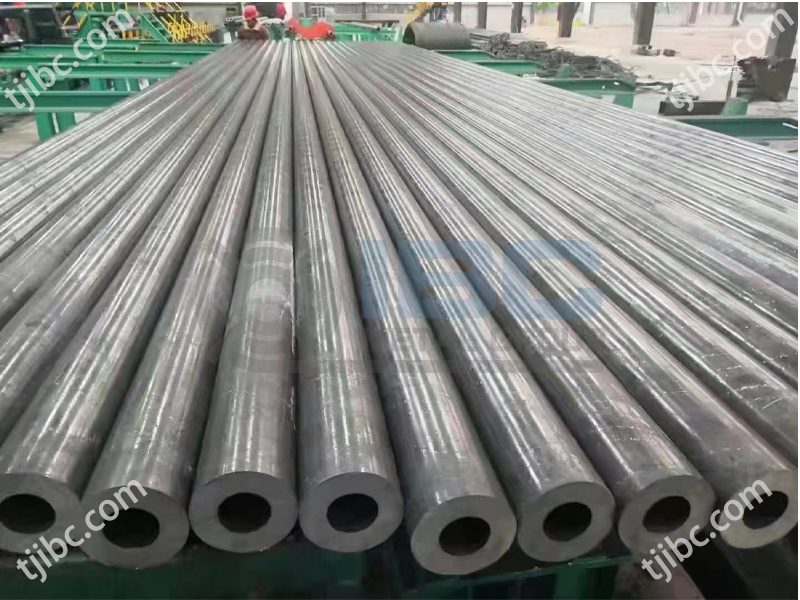

About Seamless Steel Pipes

Seamless pipes are typically crafted via cold or hot rolling. This process strengthens carbon and alloy steel to produce a sturdy yet lightweight product. While creating these tubes calls for more effort and precision, they are able to take on higher pressure levels which makes them ideal for the oil and gas industry. Furthermore, there is no visible seam that can become corroded or unsightly if the pipe is in plain sight. On the other hand, this method of production does limit its application when it comes to larger sized pipelines.

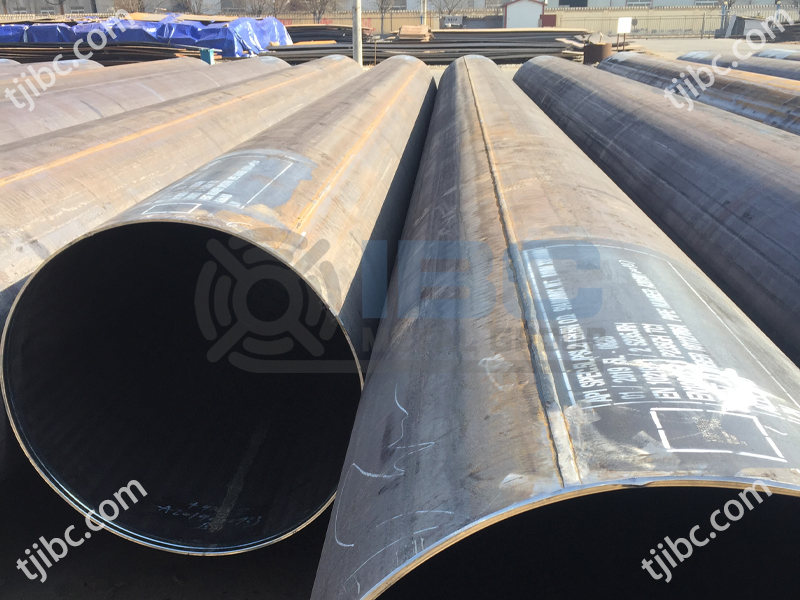

About Welded Steel Pipes

Welded pipes are designed to provide precision when it comes to diameter and wall thickness, making them an ideal choice for construction projects that require accuracy. Due to their flexibility, welded pipes can take on many forms of different sizes, including ones big enough for large-scale construction jobs. However, the downside is that they have thinner walls and seams that make them more susceptible to pressure and corrosion. As a result, these pipes are usually cheaper than other types but may not always be the best solution in certain circumstances.

Seamless Steel Pipe Vs. Welded Steel Pipe

Each pipe has advantages and disadvantages depending on your ultimate use. While seamless has a higher pressure rating, that might not be the highest priority for your project. The lower cost and larger potential size of a welded pipe might be more important if you’re building a bridge and need a lot of pilings.

Have a Project That Needs Steel Pipes?

Whether you’re constructing a tall building or a wide bridge, steel pipe piles offer a deep and robust foundation to support the load. Seamless pipes are more pressure resistant, yet costlier and less flexible. Welded pipes are usually the best option for large construction projects, as they provide accurate dimensions while keeping costs minimal. If you have any doubts about which steel pipe is right for your project, reach out to our team at the closest global office – they’ll be happy to help!

Contact with us today!