ASTM A500 steel pipe is manufactured according to the ASTM A500 standard which specifies its use in construction of bridges and buildings, as well as general structural applications such as frames, roll cages, truck racks, trailers, railings, and more. IBC Metal Group produce a complete range of sizes that are designated in the specification with three varieties of steel Grade available- A through C.

Contact with us today for more information!

What is ASTM A500 Steel Pipe?

ASTM A500 (also known as A500/A500M) carbon steel tubing is a standard specification for cold-formed welded and seamless carbon steel structural tubing. The shape could in round, square and rectangular shapes. ASTM A500 is the most common specification in North America for Hollow Structural Sections (HSS). This is a standard set by the standards organization ASTM International, a voluntary standards development organization that sets technical standards for materials, products, systems, and services.

What Are the Grades of A500 Pipe?

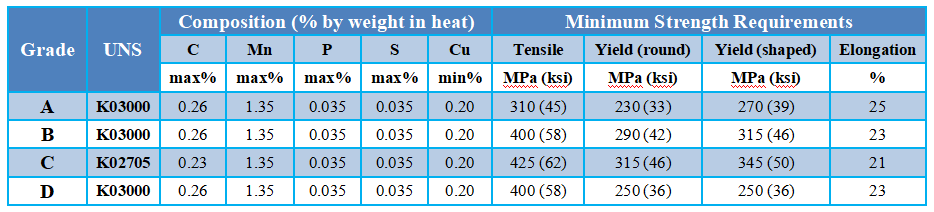

Used for load-bearing structures that require high-yield strength, A500 steel comes in four grades — A, B, C, and D. A500 cold-formed tubing comes in four grades based on chemical composition, tensile strength, and heat treatment. The yield strength requirements are higher for square and rectangular than for round tubing. The minimum copper content is optional. Grade D must be heat treated.

Chemical Composition of ASTM A500

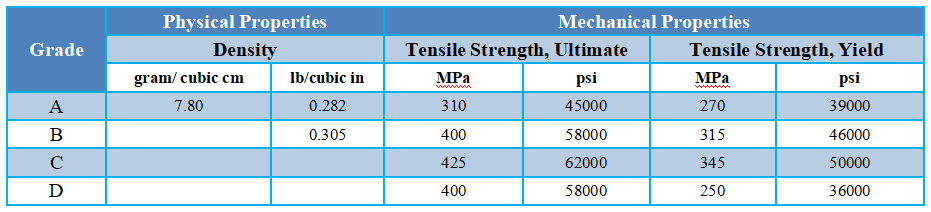

Mechanical Properties of ASTM A500

Difference Between ASTM A500 & ASTM A53

Do you know the distinctions between ASTM A53 and A500? The former is the norm for steel, black lacquer coated, welded as well as seamless steel pipe intended to be used in mechanical and pressure situations, as well as ordinary steam, water and air lines. On the other hand, ASTM A500 is the spec for cold-formed, welded and seamless carbon structural tubing, with three grades – A through C – that are meant for construction and structural applications.

A500 pipe is available in a wide range of shapes, including round, square and rectangular, unlike A53 piping, which is only round. In addition to these oft-cited differences in intended use between the two steel products, many additional details are critically important for engineers, especially as they relate directly to matters of cost and quality.

(1) Quality and Yield Strength

Take note of yield strength when engineering a building. A500 is the stronger option; compared to A53, it results in less steel by weight and provides cost savings. There is furthermore no additional cost to use Grade C, which has a yield strength around 10% higher than its predecessor Grade B. Therefore, it makes sense to utilize the highest quality tube available.

(2) Designation

Engineers frequently wonder why there are so many fewer options for A53 pipe than A500 rounds. A53 pipes are designated using a nominal pipe diameter in inches, plus one of three scheduled wall thickness. They are sized this way because A53 pipes—designed to carry pressurized steam, air or water—must work with standardized fittings and valves.

A500 tubes offer much more precise designations than other types, and are better equipped for efficiency. Their outside diameters and wall thickness in inches are listed with three decimal places. For a building column, A500 round can be specified as HSS8.625×0.322, with an OD tolerance of +/-0.75% and wall of +/-10%, both tighter than those of the equivalent A53 8 inch standard pipe at +/-1% and -12.5%. Additionally, A53 is limited to pipes of 21’ or 42’ length; A500 rounds can be produced from 20’ to 75’ in length.

(3) Tolerances

As you see, A500 tolerances are tighter than A53 pipe tolerances. When you are selecting section sizes for your structural design. You will have more confidence that you will not only get the cross-sectional dimensions but also the necessary straightness with A500. As A500 producers must also adhere to a straightness tolerance specified in A500. With A53, there is no specification in the standard for how straight the pipe must be.

(4) Inside and Out

Thus far, we’ve focused on these two options’ structural characteristics, but what happens on the outside matters just as much. Because the A53 pipe produced to carry pressurized steam, water or gas. The manufacturer must hydrostatically test their product, ensuring that it can withstand pressure when in use. If you are using A53 piping for structural applications. You can expect to pay for tests your application does not require.

Consider, too, that when you use an A53 pipe. You will pay in part for the sealant that producers use to coat the outside of the pipe. In order to weld to these pipes. A fabricator must remove the sealant you have paid for, an unnecessary cost and extra step in the fabrication process. The bare surface of the A500 tube makes it easier to paint, as well.

Inside and out, the differences between A53 pipes and A500 tubing make clear: these two options are far from synonymous. For a host of structures—from building columns, braces, trusses, space frames and towers—A500 is clearly the appropriate choice.

(5) Advantages & Disadvantages

In addition to being easy to weld and machine, A500 steel can be cold worked and has a pleasing appearance. Specifically, A500 steel is similar to A53 steel in popularity and use. ut it is stronger, corrosion resistant, and has a higher strength-to-weight ratio, so it is more expensive than A53 steel.

Chemically and structurally, A500 better resembles A36 steel. The major difference between the two is in their use. Though both are hot rolled steel, A36 has many shapes and types. Including rectangular bar, round bar, round tube, square bar, angle, channel, plate, tread plate, and shafting. A500 on the other hand just used for metal pipes and tubes albeit these can be round, square, or rectangular.

A500’s primary advantage is its relative strength. Consequently, this steel grade works well for structural applications such as pipes, tanks, boilers, and heavy-duty equipment. The metal’s major disadvantage is its relative heat intolerance. It will shatter rather than shape at high temperatures.

Conclusion

Among the products offered by IBC Metal Group are coated and uncoated pipes, welded and galvanized pipes, square structural tubes, rectangular structural tubes, and round structural tubes in grades B and C. We offer both welded and seamless versions of this tubing with a periphery of 88 in. [2235 mm] or less, and a wall thickness of 0.875 in. [22 mm] or less. Grade D tubing requires heat treatment. For more information, please call us.

Contact with us!