IBC (Tianjin) Industrial Co., Ltd manufacturer & export 4145H Alloy Steel Bar for decades years. AISI 4145H is a chromium – molybdenum low alloy tempered steel. It has improved harden-ability and commonly used in the high strength condition with min.110 KSI yield.

For more information, or you need it in your projects, please contact with us!

4145H Alloy Steel Bar Making Process

AISI 4145H alloy steel bar manufactured via Electric Arc Furnace, followed by Ladle Refining and Vacuum Degassing and is either cast into bottom poured wide end up ingots, or Continually Cast. AISI 4145H steel adopts appropriate composition design and advanced production technology to obtain good mechanical properties, so that it can meet the performance requirements of 4145H steel in the process of oil drilling.

The Production Process of AISI 4145H Steel:

Molten steel pretreatment → Converter → LF→ RH→ Continuous casting-continuous casting → Hot delivery → Heating → Hot rolling/Forging → Heat Preservation → Straightening → Annealing → Grinding → Inspection → Delivery

Size Range

Diameter: 20mm – 900mm or customized according to your requirements.

Length: 1000mm – 12000mm or customized according to your requirements.

Product Standards:

- ASTM A29/ 29M (4145H) SAE J1268

- UNS H41450

- ASTM A304

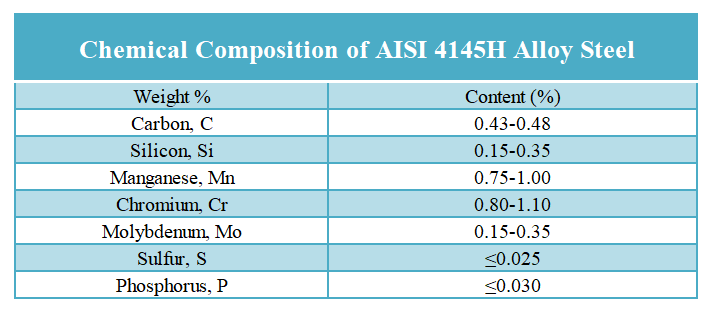

Chemical Composition

The chemical composition of AISI 4145H alloy steel are outlined in the following table:

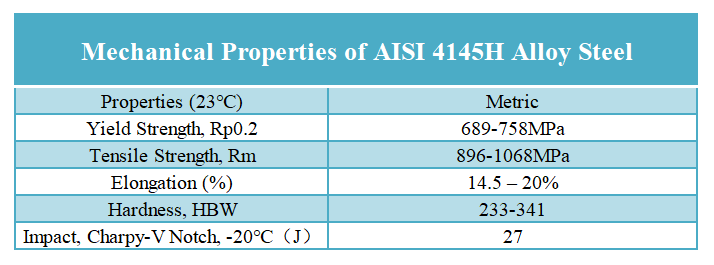

4145H Alloy Steel Bar Mechanical Properties

The mechanical properties of AISI 4145H alloy steel are displayed in the following table:

Heat Treatment

AISI 4145 Steel Bar Quenching & Tempering.

AISI 4145 steel can obtain satisfactory overall performance through quenching and tempering heat treatment to meet the requirements of petroleum equipment. Heating temperature and holding time are two important parts that affect the quality of quenching. The structure obtained after austenitization achieved by heating will affect the performance of the material after quenching. For AISI 4145 steel, the appropriate quenching temperature is between 840-860ºC, and the holding time depends on the thickness of the material.

Tempering process should follow after quenching immediately. When 4145 steel used as drill collar steel, it needs to be tempered at a high temperature of 560-630ºC to obtain tempered sorbite. And finally obtain good comprehensive mechanical properties.

Surface Conditions of 4145H Alloy Steel Bar

Black/Peeled/Smooth Turned

Applications of 4145H Alloy Steel Bar

AISI 4145H is a low alloy steel suitable for down-hole drilling tools such as subs, x-overs, drill collars, pup-joints and fishing tools. General engineering applications include components exposed to heavy strain, such as shafts, gear, bolts etc. AISI 4145H can also be used in hardened condition as machine parts exposed to heavy wear.

IBC is one of the leading China Special Steel manufacturers and suppliers. If you want to buy or import best high-quality 4145h alloy steel bar professional company, factory, seller, and exporter please feel free to contact us.

AISI 4145H Steel Buying Guide

Usually when we talk about the oil and gas industry, the first thing that comes to mind is the representative steel grades of the Cr-Mo series. Such as AISI 4140, AISI 4130, AISI 4340 and AISI 4145H. Indeed, they all play a heavy role in industrial applications.

The AISI 4145H we are talking about here, with its unparalleled performance characteristics. Completely replaces the AISI 4140 steel used in the past and now is used as a special steel for oil drill collars.

From our guide, we’ll tell you everything you need to know about AISI 4145H as a steel for oil drill collars, which we believe will help you find high quality AISI 4145H steel more easily.

For more information, or you need it in your projects, please contact with us!

Equivalent Grade:

- EN 1.7225

- ASTM A255

- UNS G41450

- AISI 4145H Modified

Contact with us!

Related Products

Quick FAQs for AISI 4145 Steel

Is AISI 4145 Steel For Oil Drill Collars?

AISI 4145 steel has good comprehensive mechanical properties and corrosion resistance after heat treatment, and is the most widely used medium-carbon low-alloy steel in the international petroleum industry.

Due to its good strength and toughness and resistance to H2S corrosion. AISI 4145 Steel can use as a drill collar material in the process of oil exploitation, and also be used for the production of oil drill pipes. Especially for its excellent resistance to corrosion in oil and gas environments. AISI 4145 steel also used in the production of petroleum pipelines.

Is AISI 4145 Steel Corrosion Resistant?

AISI 4145 steel mainly used in the production of oil drill collars. And can also be used in the production of oil casing, which are used in corrosive environments in oil fields.

The good structure of AISI 4145 steel (tempered sorbite) can improve the corrosion resistance. In addition, the alloying element Cr can be dissolved in F, which can improve the corrosion resistance. And the Mo element also helps to improve the corrosion resistance.

Can AISI 4145 Steel be Welded?

Calculated from the composition of AISI 4145. its CE is about 0.85,and its weldability is very poor. When welding AISI 4145 steel, preheating before welding and post-welding heat treatment are mandatory. Strict welding process for AISI 4145 can ensure the reliability of welding.

What is AISI 4145H?

When add “H”,this means that AISI 4145 steel is required to ensure hardenability. In fact, there is no difference in composition between AISI 4145H and AISI 4145 steel.

What is AISI 4145H MOD?

MOD means Modify. Therefore, AISI 4145H MOD is an improvement on the basis of AISI 4145 steel, which may be due to changes in composition or more stringent performance requirements.