IBC Metal Group produce & supplies alloy structure steel in Round, Square and Flat Bar which widely used in the manufacture of automobiles, locomotives, marine vessels and heavy machinery. Our superior quality has been highly appraised by users all over the world.

Supply Range of Alloy Structure Steel

Product: Alloy structural steel

Form: Round,Square and Flat Bar

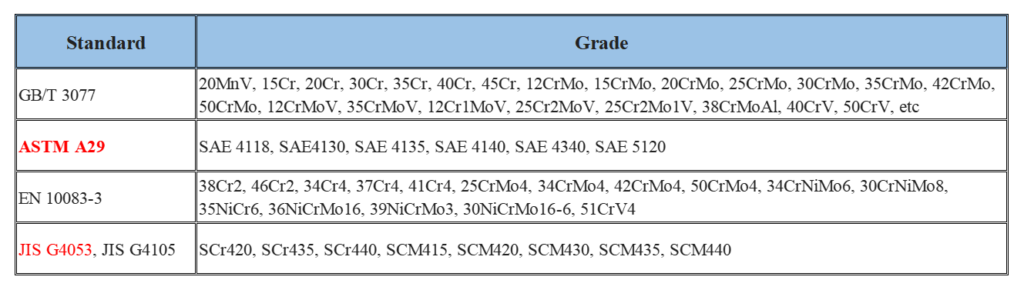

Standard: ASTM A29,EN 10083-3,JIS G4053, JIS G4105

Main products: ASTM A29 SAE4130, ASTM A29 SAE 4140, JIS G4053 SCr440, JIS G4105 SCM435

What is Alloy Steel?

Alloy steel mixed with a number of alloying elements. Such as silicon, chromium, molybdenum, boron, vanadium, nickel, aluminum, etc. These alloying elements increase the strength, toughness, hardness, and wear resistance of the alloy steel. Some of the alloying elements and their effects shown below.

- Cobalt: Improves the hardness, Increases wear resistance and toughness.

- Manganese: Strengthens surface hardness, hammering, and shocks, enhances resistance to strain

- Chromium: Improves toughness and wear resistance, and increases hardness.

- Molybdenum: Increases resistance to heat and shock, and improves strength.

- Nickel: Enhances strength and toughness, and increases corrosion resistance.

- Vanadium: Improves strength, enhances sock and corrosion resistance, grows toughness

- Tungsten: Improves strength and toughness, enhances corrosion resistance

- Chromium-Vanadium: Greatly enhanced tensile strength which makes alloy hard but easy to bend and cut.

Types of Alloy Steel

Alloy steel is the combination of steel with a number of elements to get unique characteristics and properties. It has two types based on the weight of elements used to form the alloy steel that ranges from 1% to 50%. The flowing will mention two groups of alloy steel.

① High-Alloy Steel: It has a high percentage of alloying elements. The most common type of high alloy steel is stainless steel which contains up to 12% of chromium. Chromium makes a thin oxide layer outside of the steel which known as the latent layer. The big number of chromium provides extended protection from erosion. This type of alloy is a little costly than low alloy steel. Thus, it mainly used in automobiles and industrial equipment.

② Low-Alloy Steel: It has a lower percentage of alloying elements ranging from 1 to 5 percent. This steel has different strengths and applications depending upon the alloy used. Besides, large diameter flanges use this type of alloy to get specific mechanical properties. Consequently, low alloy steel is useful for a variety of projects in a vast number of industries such as studding outlet production and seamless rolled ring forging.

Application of Alloy Steel

The alloy steel used in a number of industrial sectors and it helps manufacture hundreds of products. Their extreme strength, hardness, toughness, and machinability make them the most demanding material for many industries. Consequently, alloy steel is ideal for structural components, automotive, mining, machinery, railway, and many other industries.

- Construction Industry

- Aerospace Industry

- Mining Industry

The application of alloy steel is very wide and depends on the type of alloy steel. Some alloy steels used to manufacture pipes, particularly those for energy-related uses. While others utilized in the production of corrosion-resistant containers, silverware, pots, pans, and heating components for toasters and other kitchen equipment. Alloy steels can be divided into two primary categories: low-alloy steels and high-alloy steels. The application of alloy steels is mainly determined by the category that they fall in.

Low-alloy steels are employed in a variety of industrial sectors due to their strength, machinability, and affordability. They found in ships, pipelines, pressure vessels, oil drilling platforms, military vehicles, and construction equipment.

High-alloy steels, on the other hand, can be expensive to produce and challenging to work with. However, they are perfect for automotive applications, chemical processing, and power generation equipment due to their high strength, toughness, and corrosion resistance.

Conclusion

IBC’s main alloy structural steel products including ASTM A29 SAE4130, ASTM A29 SAE 4140, JIS G4053 SCr440, JIS G4105 SCM435. More information about our inventory,call for us or send your inquiry.

Contact with us today!