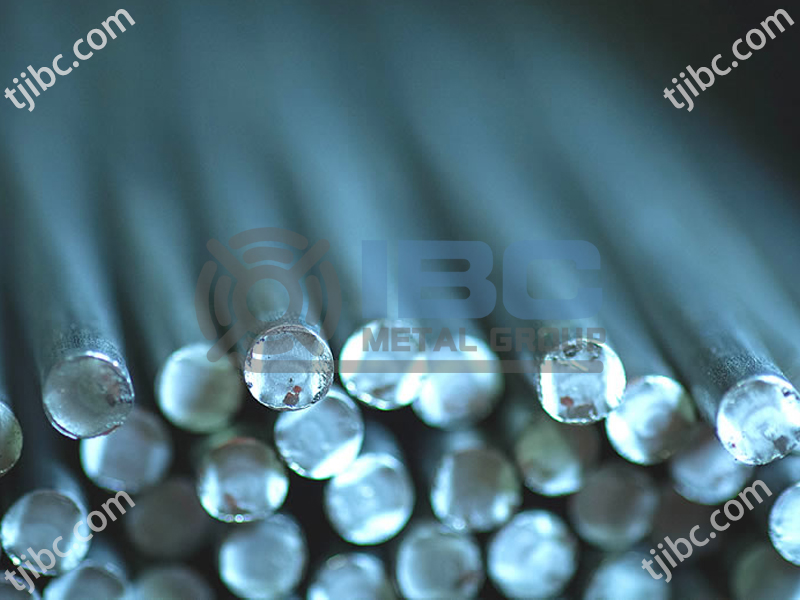

4140 Alloy Steel Bar Manufacturer

IBC Metal Group supply all sizes of 4140 alloy steel bar to all over the world.In addition to its high quality, it has a competitive price that makes it popular among other countries’ customers. Compared to other types of steel, 4140 steel bar has a carbon content of 0.4% or lower, making it more corrosion resistant. In addition to building construction, it is also used to manufacture tools.

What is 4140 Alloy Steel Bar?

AISI SAE 4140 is a chromium molybdenum alloy steel widely used in high tensile components such as axles, shafts, bolts, and gears. AISI 4140 is stronger and heat-resistant than AISI 4130 chrome moly alloy steel, despite not being as welding-friendly as AISI/ASTM 4130. It has a slightly higher carbon content than AISI 4130.

Supply Range for AISI 4140 Alloy Steel Bar

4140 Steel Round Bar: Diameter 8mm – 3000mm

AISI 4140 Steel Plate: Thickness 10mm – 1500mm x Width 200mm – 3000mm

4140 Steel Grade Square: 20mm – 500mm

Surface Finish: Black, Rough Machined, Turned or as per given requirements.

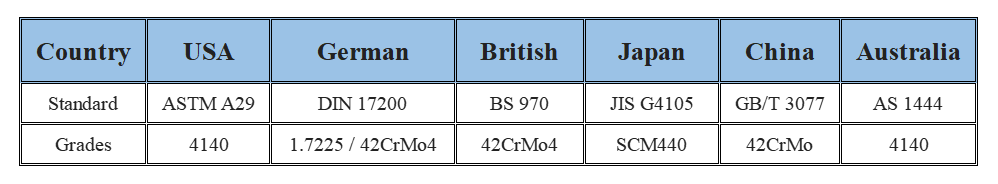

Common 4140 Steel Specifications

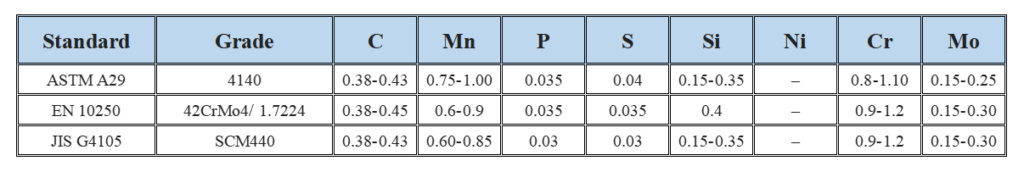

4140 Alloy Steel Bar Chemical Composition

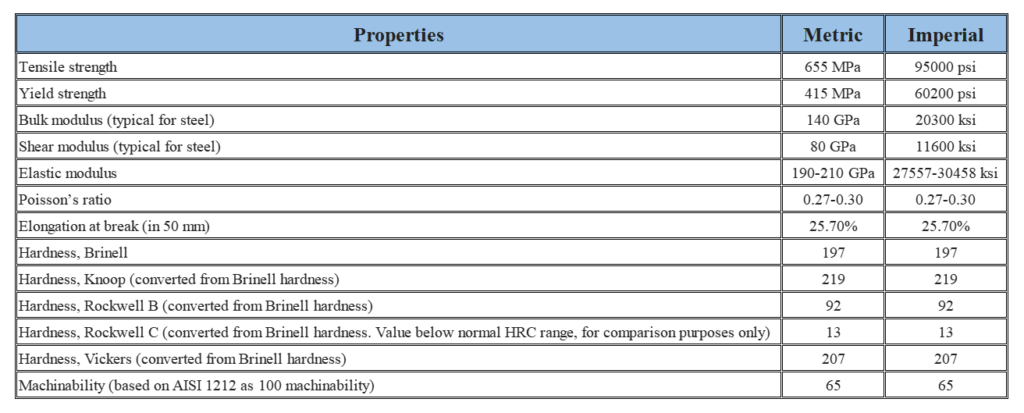

Mechanical Properties of AISI Alloy 4140 Steel Bar, Plates, Square

Forging

Preheat the steel carefully, heat to 1150℃ – 1200℃ maximum, hold until temperature is uniform throughout the section. Do not forge below 850℃. Following forging operation the work piece should cool as slowly as possible.

AISI 4140 Steel Grade Heat Treatment

Annealing – Heat ASTM 4140 steels to 800℃ – 850℃, hold until temperature is uniform throughout the section and cool in furnace. Normalizing – Heat steel alloy 4140 to 870 ℃ – 900 ℃, hold until temperature is uniform throughout the section, soak for 10 – 15 minutes and cool in still air. Tempering – Re-heat 4140 grade steel to 550℃ – 700℃ as required, hold until temperature is uniform throughout the section, soak for 1 hour per 25 mm of section, and cool in still air.

Hardening of AISI Alloy Steel 4140 – AISI alloy 4140 steel bar, plate and square can be hardened by cold working, or heating and quenching. SAE 4140 alloy steel usually supplied ready heat treated to hardness in 18-22 HRC. If further heat treatment required, then heat to 840℃ – 875℃, hold until temperature is uniform throughout the section, soak for 10 – 15 minutes per 25 mm section, and quench in oil, water, or polymer as required.

Application of AISI Alloy Round 4140 Steel Bar

Applications for ASTM 4140 alloy steel bar, flat or plate material are varied and include components, adapters, arbors, strippers, holder blocks, mold bases, ejectors and back up and support tooling. Fixtures, jigs, molds, cams, drill collars and axle shafts are also made from this durable steel. Further uses include bolts, crankshafts, stubs couplings reamer bodies and axles too. Other potential uses are shafting parts for hydraulic machinery such as rams and gears. Sprockets gear racks chain links spindles tool bodies holders tie rods connections rods chuck bodies collets conveyor pins rolls ejector pins forks guide rods hydraulic shafts lathe spindles logging parts milling spindles motor shafts nuts pinch bars pinions pump shafts boring bars tracks slides wear strips or parts forming dies brake dies trim dies bolsters machinery parts and components etc.

Why Buy a 4140 Steel Bar?

There are many reasons why you should buy a 4140 bar. For starters, it has a high tensile strength and is corrosion resistant. It is also lightweight – which means that it’s easy to carry. The 4140 steel bar is a popular choice for those who need a high-quality steel bar. There are many reasons why this type of steel is preferred over other types of steel bars.

The first reason is that the 4140 steel bar has a higher tensile strength than other types of steel. The second reason is that it has better machinability, which means it’s easier to work with and less likely to have any machining defects. The third reason is that the 4140 steel has greater corrosion resistance compared to other types of steels, which means it can last longer without rusting or corroding.

Conclusion

4140 steel bar stock is a type of steel with high strength and stiffness. It used in the construction industry for the manufacture of bridges, buildings, and other structures. Also, the 4140 steel bar stock has many advantages over other types of steel such as being able to be cut, welded, drilled and bent without losing its strength. It is also heat resistant to a certain extent.

IBC Metal Group is here for you if you need an efficient alloy steel round bar supplier and a centerless ground bar supplier who provides you with quality 4140 Alloy Steel bar! We work closely with our clients to ensure that their precision ground bars delivered to the correct specifications. Call us or request a quote!

Contact with IBC Metal Group