IBC Metal Group is a worldwide exporter of T1 High Speed Tool Steel, more commonly referred to by its AISI/ASTM designation. This original high-speed tungsten steel distinguished by its grey colour and the incorporation of tungsten carbide, resulting in improved heat resistance, red hardness and wear resistance. In addition to T1, there are other tool steels available on the market ranging from T2 to T15. It is important to note that each grade boasts unique chemical composition and physical, mechanical and thermal characteristics.

Supply Range of T1 High Speed Tool Steel

T1 High Speed Tool Steel (T1, 1.3355, HS18-0-1, SKH2)

- T1 Steel Round Bar: Diameter 2mm – 200mm

- Steel Flat T1: Thickness 2-20mm x Width 10-100mm

- T1 Steel Plate: Thickness 2-200mm x Width 200-610mm

- Surface Finish: Black, Rough Machined, Turned or as per given requirements.

Get in touch with us if you need anything else besides T1 steel. IBC steel manufacturing company is one of the biggest suppliers of T1 steel in China. We are always available to assist and supply any type of high-speed steel at an affordable cost.

Applications of ASTM/AISI T1 Tool Steel

Generally, high speed steels used for machining at high speeds. HSS T1 steel materials widely used for: Broaches, Drills, Hobs, Knurling Tools, Lathe Tools, Milling Cutters, Nut Piercers, Planer Tools, Reamers, Shaving Tools, Taps, Thread Cutting Tools.

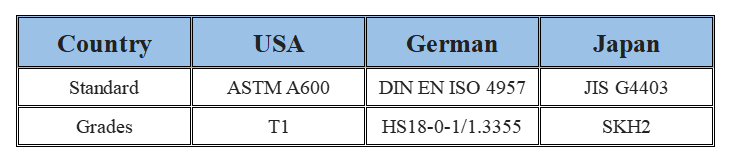

Relevant Specification of AISI T1 High Speed Tool Steels

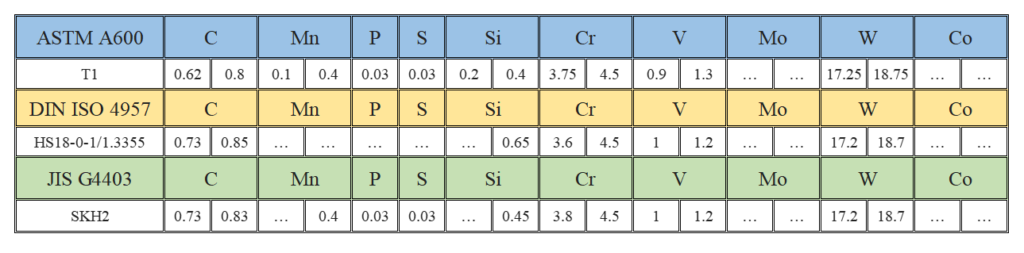

AISI T1 Tool Steel and Equivalents’ Chemical Composition

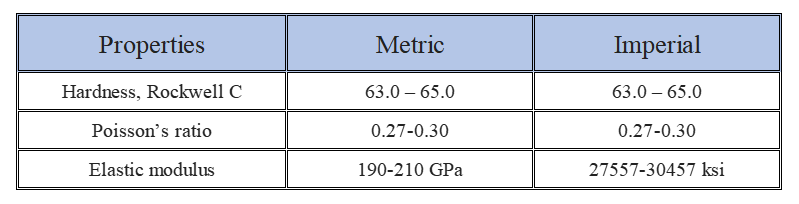

T1 HSS is high speed tool steel containing 18% tungsten, which has good cutting properties and high toughness. With 18% tungsten, it is the most effective high-speed steel grade based on W, with high resistance to wear, red hardness, and toughness. With high tensile strength and a hardness up to 63-66 HRC post heat treatment, tungsten in this tool steel makes it easy to cut them.

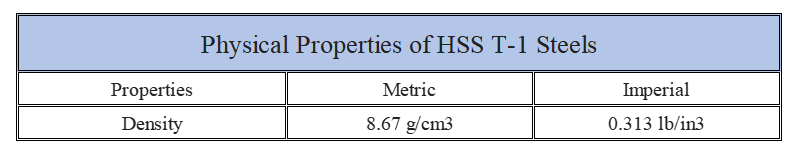

High Speed Steel T1 Tool Steel Mechanical Properties

Mechanical Properties of T-1 Steel

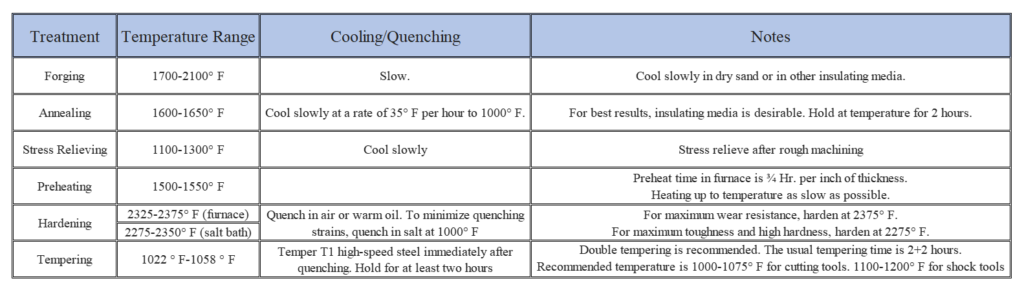

Heat Treatment

Annealing —— 1. Annealing recommended after hot working and before re hardening; 2. Heat the temperature to 850°C at a rate of no more than 220°C per hour; 3. Hold at the temperature for one hour per inch of thickness(at least two hours); 4. Cool slowly in the furnace or in air to ambient temperature; 5. The resultant hardness achieved should be Max 255HB or lower.

Hardening —— 1. Preheat T1 to 480-500°C ,then up to 880-900°C. 2. Heat to the final hardening temperature of 1200°C and make sure the material must heat through. 3. Quench in the warm oil,and then complete the quench in air.(care MUST taken at this step); 4. T1tool steel is suitable for vacuum hardening.

Tempering —— 1. Tempering must do immediately after quenching; 2. Heat thoroughly and uniformly to the tempering temperature;3. Hold at the temperature for at least two hours (one hour per inch of the total thickness); 4. Triple tempering strongly recommended for T1 tool steel.

Forging of AISI HSS T1 Tool Steel

Preheat T1 high speed tool steel uniformly and slowly to 850-880°C. Increase the forging temperature for T-1 tool steel until 1050-1130°C. T1 HSS tool steel should be cooled very slowly after forging.

AISI/ASTM T1 Tool Steel Heat Treatment and Properties

Conclusion

The IBC (Tianjin) Industrial Co., Ltd website has been visited by many people throughout the world. IBC is one of the most successful and trusted T1 steel manufacturers and suppliers in China. You can get the best quality T1 steels in the following categories – round bars, square bars, flat bars, sheets and wires.

For your projects, we can provide you with high quality T1 steel at a reasonable price. All you need to do is send us your inquiries on T1 steel and request the latest offer. It will be available to you in a matter of minutes. For an immediate quote and pricing of T1 High Speed Tool Steel, please contact us by email or through our customer service line.

Related Products

Contact with us!