IBC Metal Group could produce M42 high speed tool steel and export all kinds of these special steels. M42, a type of molybdenum high speed tool steel, has good wear resistance and hot hardness along with high hardness values.

There are two types of high speed tool steels. One is Molybdenum high-speed steels. And the other one is Tungsten high-speed steels. Molybdenum steel types M1 to M10 have tungsten whereas cobalt not found in type M6. Cobalt totally absent in these types of molybdenum high-speed steels. Molybdenum high-speed steels, also known as group M steels, comprise less initial cost.

Supply Range of M42 High Speed Tool Steel

(M42, SKH59, HS 2-9-1-8, 1.3247)

- M42 Steel Round Bar: diameter 2mm – 200mm

- M42 Steel Flat: thickness 2-1000mm x width 10-100mm

- Steel Plate M42: thickness 2-200mm x width 200-610mm

- Surface Finish: Black, Rough Machined, Turned or as per given requirements.

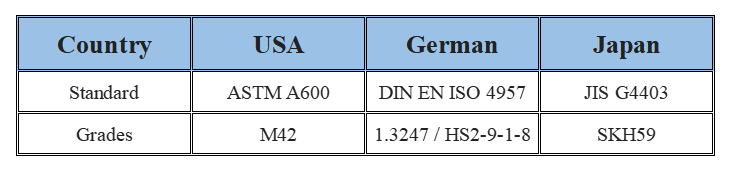

Common M42 Related Specifications and M42 High Speed Tool Steel Equivalents

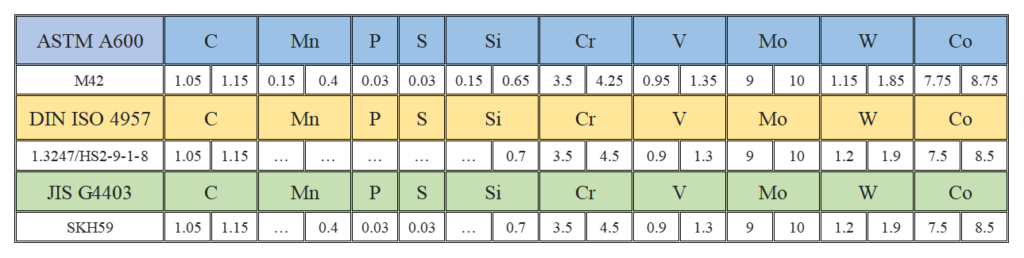

AISI M42 Tool Steel Chemical Composition

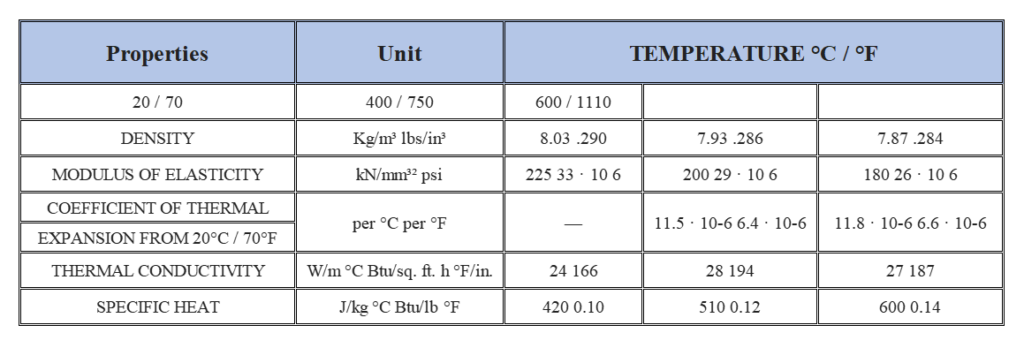

Physical Properties of AISI M42 HSS Tool Steel

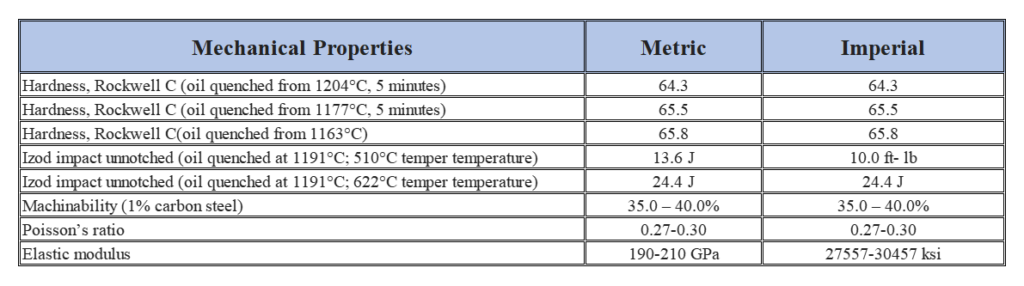

Mechanical Properties of M42 Steel

Forging of High Speed M42 HSS

Pre heat the M42 high speed steel slowly and uniformly to 650-760°C and equalise. Then increase more quickly to the forging temperature of 1010-1150°C and equalise prior to forging. Do not allow the forging temperature to drop below 980°C, if this occurs re heating will be necessary. Always cool the m42 high speed steel very slowly after forging.

Heat Treatment of HSS M42

① Annealing : Firstly, AISI M42 high speed steel heated at 871°C (1599°F). And then cooled slowly in a furnace. ② Stress Relieving: To relieve stresses created by extensive machining or tooling with complex geometries. Heat in a neutral atmosphere for 1 to 2 hours after reaching a temperature of 1110 to 1200°F (600 to 650°C), followed by slow cooling in the furnace. ③ Hardening: AISI HSS M42 is preheated to 871°C (1599°F), soaked and finally heated to 1204°C (2199°F). ④ Tempering: Tempering M42 tool steel at 560°C / 1040°F or higher 3 times for at least 1 hour at full temperature is recommended.

Application of M42 Tool Steel High Speed

Because of its superior red-hardness as compared to more conventional high-speed steels, High-speed steel M42 steel widely used in metal manufacturing industries and in cutting tools manufacturing. This allows for shorter cycle times in production environments due to higher cutting speeds or from the increase in time between tool changes.

AISI M42 tool steel is a high-speed steel suitable for cutting tools such as, twist drills, broaches, taps, milling, cutters, saws, reamers etc. In terms of performance, HSS grade M42, a steel used in conditions where the demand for hot hardness is of great importance. Where high performance is essential. Typically employed to machine the super alloys and exotic. AISI HSS M42 tool steel employed in drills, hobs, taps, end mills, milling cutters, form and gear cutters, broaches and chasers.

Conclusion

IBC (Tianjin) Industrial Co., Ltd could produce all kinds of special steel, such as 4340 Alloy Steel Bar, 4130 Alloy Steel Bar, T1 High Speed Tool Steel, T4 High Speed Tool Steel, T5 High Speed Tool Steel and so on. AISI high speed M42 tool steel is a conventionally manufactured cobalt alloyed high-speed steel. The various stages of the manufacturing process are chosen and controlled so that an end product is obtained with a good structure in terms of carbide size and distribution. This is a distinct advantage for the finished tool.

Contcat with IBC Metal Group today! Email us or fill the form, our quick reply and best service.

Contact with us!