H13 Tool Steel is a versatile chromium-molybdenum hot work steel that widely used in hot work and cold work tooling applications. The hot hardness (hot strength) of H13 resists thermal fatigue cracking which occurs as a result of cyclic heating and cooling cycles in hot work tooling applications. Because of its excellent combination of high toughness and resistance to thermal fatigue cracking (also known as heat checking) H13 used for more hot work tooling applications than any other tool steel. H13 Hot Work Tool Steel is classified as group H steels by the AISI classification system. This series of steels start from H1 to H19.

Supply Range for AISI H13 Tool Steel

Hot Work H13 Steel Round Bar: Diameter 8mm – 400mm

H13 Steel Plate: Thickness 16mm –500mm x Width 200mm – 800mm

H13 Steel Slab: 200mm x 500-800mm

Surface Finish: Black, Rough Machined, Turned or as per given requirements.

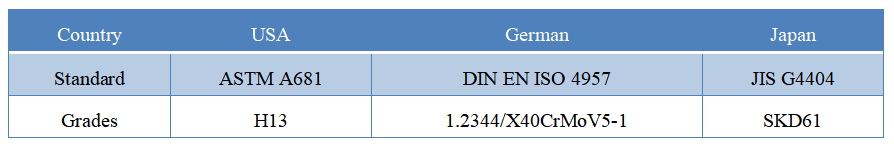

H13 Hot Woek Tool Steel Related Specifications

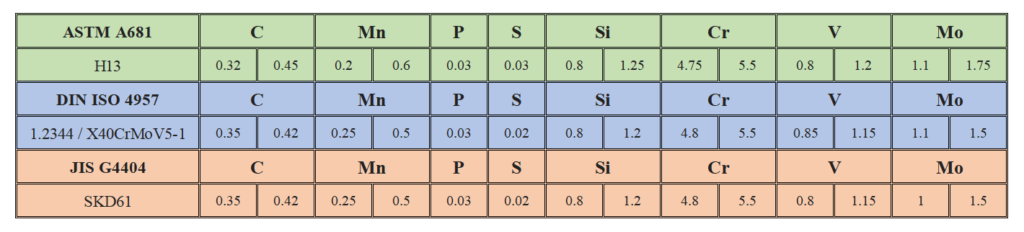

H13 Tool Steel Chemical Composition

In terms of chemical composition, H13 tool steel includes Carbon in the range as 0.35-0.45, Chromium as 4.75-5.50, Molybdenum as 1.10-1.75, Manganese as 0.20-0.50, Vanadium as 0.80-1.20, Silicon 0.80-1.20, Phosphorus as 0.030 and Sulfur as 0.030 at the max. Temperatures for various operations carried on such as annealing range from 1550 to 1650 °F, 1825-1900 °F for hardening, 1000-1200°F for tempering and 38-53 °F for Rockwell C.

AISI H13 Steel Mechanical Properties

Physical Properties —— Physical properties of H13 tool steel comprise of its density and melting point. The density recorded as 7.80 g/cm3 for 20°C, while melting point is recorded as 1427 °C.

Mechanical Properties —— H13 tool steel in terms of its mechanical properties tends to show a behavior that varies with heat treatment. H13 tool steel records a reduction of area as 50% and modulus of elasticity as 215 GPa at 20 °C. The ranges for tensile strength in terms of ultimate and yield vary as 1000-1380 MPa and 1200-1590 MPa respectively. Value of Poisson’s ratio is recorded in the range of 0.27-0.30.

Thermal Properties —— In terms of thermal properties, the expansion recorded as 10.4 x 10-6/°C while temperature ranges from 20-100 °C. H13 tool steel has a thermal conductivity of 28.6 W/mK at 215 °C.

Forging of H13 Tool Steel

Heating for forging must be done slowly and uniformly. Soak through at 1900°-2000°F and reheat as often as necessary, stopping work when the temperature drops below 1650°F. After forging, cool slowly in lime, mica, dry ashes or furnace. H-13 should always annealed after forging.

Heat Treatment for H13 Tool Steels

Annealing —— Annealing must be performed after hot working and before re-hardening. Heat slowly to 1550°-1650°F, hold until entire mass heated through, and cool slowly in the furnace (40F per hour) to about 1000°F, after which cooling rate increased. Suitable precautions taken to prevent excessive carburization or decarburization.

Application of AISI H13 Tool Steel

Applications: Inserts, cores, and cavities for die casting dies, die casting shot sleeves, hot forging dies, extrusion dies, and plastic mold cavities and components that require high toughness and excellent polishability.

Other applications include:

- Ejector pins for injection mold

- Inserts and core pins for injection mold

- Cavities for Casting Dies

- Forging and Extrusion Dies

- Plastic Mold Cavities

- Perishability

- Shrunk rings (cemented carbide dies)

- Wear-resisting parts

- Shot sleeves for Die Casting

- Trimming dies

Because of its high toughness and very good stability in heat treatment, H13 also used in a variety of cold work tooling applications. In these applications, H13 provides better hardenability (through hardening in large section thicknesses) and better wear resistance than common alloy steels such as 4140.

Conclusion

It is quite important to apply surface treatment processes on H13 tool steel in order to improve mechanical properties, especially at higher temperatures. In conclusion, good hardness, as well as blend of shock and abrasion resistance, makes H13 tools steel a great choice for tooling applications.

IBC (Tianjin) Industrial Co., Ltd could supply all kinds of special steel. We are one of leading H13 Hot Work Tool Steel manufacturer in China. With high quality together with competitive price makes it popular among our clients. For more information, please contact with us.

Contact with IBC Metal Group Today!