Size Range of 4330V Alloy Steel Bar

- Diameter: 20mm – 900mm

- Length: 1000mm – 12000mm

- Standard: ASTM A29/A29M

- Condition: Quenched + Tempered

What is AISI 4330V Alloy Steel Bar

AISI 4330V is a Nickel Chrome Molybdenum Vanadium (NiCrMoV) hardened and tempered high-strength alloy steel widely used in the oil and gas fields.

AISI 4330V is a modification of the 4330 alloy steel grade, with harden-ability and other characteristics improved by the addition of vanadium. The addition of vanadium and nickel to 4330V alloy steel helps it achieve high strength and hardness in larger diameters in comparison to similar grades such as AISI 4145. With its lower carbon content, it has better welding characteristics than AISI 4145. AISI 4330V is commonly supplied quenched and tempered with a hardness of between 35 to 39 HRC.

4330V alloy steel bar has harden-ability that is improved with the addition of vanadium. In the heat-treated condition, 4330V has good fatigue strength and toughness. Machining is best when annealed, normalized, and tempered. It also may be welded with traditional methods.

4330 Alloy Steel Bar Making Process

4430 Alloy Steel is manufactured via Electric Arc Furnace, followed by Ladle Refining and Vacuum Degassing, and is either cast into bottom-poured wide end-up ingots, or Continually Cast.

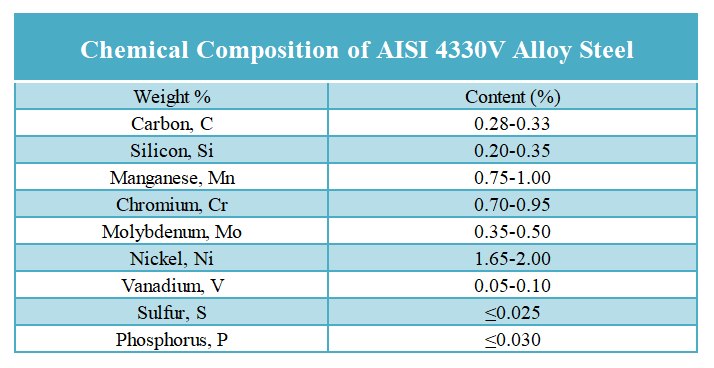

Chemical Composition of 4330V Alloy Steel Bar

The chemical composition of AISI 4330V alloy steel are outlined in the following table:

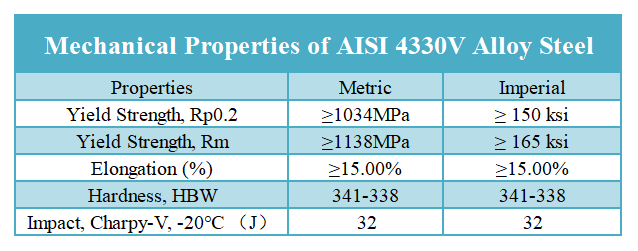

Mechanical Properties

The mechanical properties of AISI 4330V alloy steel displayed in the following table:

Weldability

Better than AISI 4145, but still challenging.

Heat Treatment

Hardened at 840 to 870°C and tempered at 600°C.

Applications

Drilling Equipment, Aircraft Landing Gear, Tool Holding Components, High Impact Machine Parts

4330V Steel Characteristics

One of the main characteristics of AISI 4330V steel is its ability to retain its strength and toughness at high temperatures. This makes it a suitable material for use in high-stress applications where the operating temperature is above 400°F (200°C). It commonly used in aerospace, energy, oil and gas well drilling equipment and various components such as gears, shafts, bolts, and fasteners.

AISI 4330V steel has a moderate carbon content of 0.28-0.33%, which gives it good strength and hardness. It also contains small amounts of chromium, nickel, and molybdenum, which improve its corrosion resistance and toughness.

In terms of machinability, AISI 4330V steel is relatively easy to work with, although it may require slightly more power and cutting speed compared to plain carbon steel. It machined using a variety of tools, including lathes, milling machines, and drill presses.

Heat treatment is an important factor in determining the final properties of AISI 4330V steel. It generally heat treated to achieve its desired mechanical properties, such as increased strength or improved toughness. Common heat treatment methods include quenching and tempering, or normalizing and tempering.

In terms of welding, AISI 4330V steel can weld using a variety of methods, including shielded metal arc welding (SMAW), tungsten inert gas welding (TIG), and metal inert gas welding (MIG). Preheat and post-weld heat treatment may be required to achieve the desired mechanical properties.

Conclusion

Overall, AISI 4330V low alloy steel is a versatile material that widely used in high-stress applications where good strength, toughness, and corrosion resistance are required. Its ability to retain its properties at high temperatures makes it particularly suitable for use in the aerospace and energy industries.

IBC (Tianjin) Industrial Co., Ltd manufacture & export 4330V Alloy steel bar for decades years. Experienced producer make it possible to provide high quality with competitive price. For more information, please contact with us!

Contact with us today!