ASTM T4 High Speed Tool Steel is similar to T1 Tool Steel materials, but with 4.25~5.75% cobalt added to increase heat resistance. The red hardness of T4 steel and the high temperature hardness is a little higher than T1 tool steel. AISI T4 tool steel is a deep hardening alloy capable of Rockwell C 64 hardness. AISI T4 tool steel is one of tungsten type high speed tool steel, which belongs to ASTM A600 specification, the standard for high speed tool steel materials.

T4 High Speed Tool Steel (T4, 1.3255, S 18-1-2-5, SKH3)

T4 Steel Round Bar: Diameter 2mm–200mm;

Steels Flat T4: Thickness 2-20mm x width 10-100mm;

T4 Steel Plate: Thickness 2-200mm x width 200-810mm;

Surface Finish: Black, Rough Machined, Turned or as per given requirements.

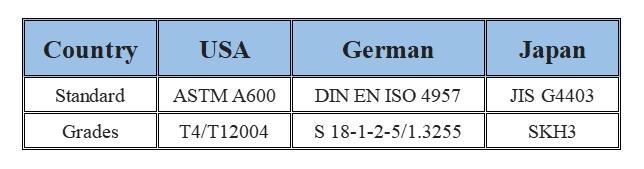

Relevant Specifications of AISI T4 High Speed Tool Steels

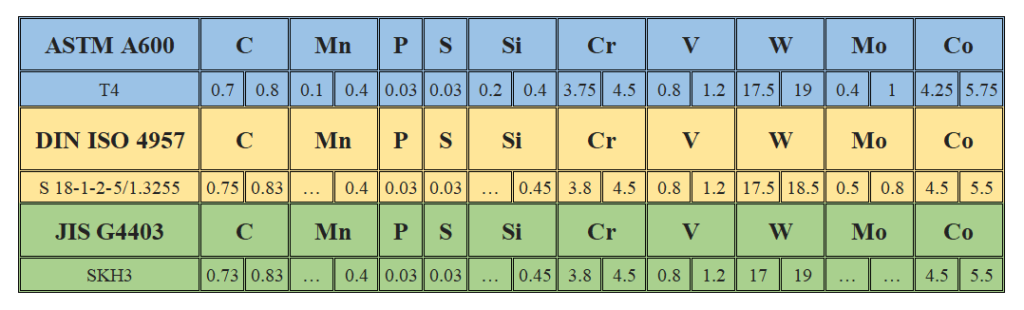

AISI T4 Tool Steel and Equivalents’Chemical Composition

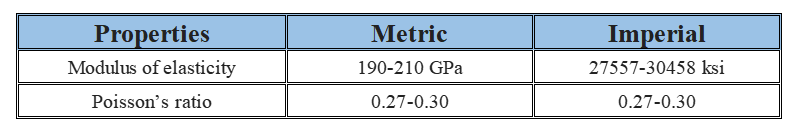

High Speed Steel T4 Tool Steel Mechanical Properties

Physical Properties of High Speed T4 Tool Steels

Physical properties (average values) at ambient temperature

Modulus of elasticity[103 x N/mm2]: 217

Density[g/cm3]: 8.70

Thermal conductivity[W/m.K]: 19.0

Electric resistivity[Ohm mm2/m]: 0.65

Specific heat capacity[J/g.K]: 0.46

Mechanical Properties of T-4 Steel

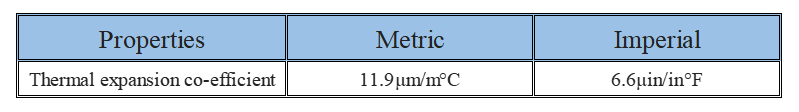

Thermal Properties of T4 Tool Steels

Forging of ASTM T4 Tool Steel Materials

Forging of T4 steel can be carried out from 850 to 1120°C(1775 to 2100°F). Preheat T4 steel material uniformly and slowly to 860-880°C. Increase the forging temperature up to 1050-1120°C. T4 HSS tool steel should be cooled very slowly after forging.

AISI/ASTM T4 Tool Steel Heat Treatment and Properties

Hardening —— Harden T4 high speed tool steel from a temperature of 1260-1290oC followed by oil,air quenching or warm bath at 550℃.Hardness after quenching is 63-66 HRC.

Annealing —— T4 steel should be annealed after hot working. Increase the temperature of T4 high speed steel to 860°C (Max220°C per hour). Hold at the temperature and then cool slowly with the furnace. The annealed hardness achieved should be below HB255.

Tempering —— Tempering temperature: 2x 560-580oC. Hardness after tempering is 64-65 HRC.

Marking & Packing

Our products like T4 High Speed Steel Round Bars packaged to make sure that there’s no damage throughout transit. Just in case of exports, customary export packaging completed in wooden boxes or cases. All T4 High Speed Steel Round Bars marked with Trademark (Company’s LOGO), Grade, Size and Lot No. On requests we can do custom marking on our products.

Applications of ASTM/AISI T4 Tool Steel

Typical applications are: Drills, Milling Cutters, Thread Cutting Tools, Knurling Tools, Cold extrusion punches Broaches etc.

AISI T4 high speed tool steels widely used as cutting tools, broaches and cold extrusion punches, turning, planing and milling cutters particular for roughing work. Planning and slotting tools, twist drills, Turning, threading dies, profile cutting tools. Heavy, cutting tools, Heavy roughing work, machining high tensile steels, difficult to machine cast steel, grey cast iron, chill castings NF metals & non-metal material.

Conclusion

AISI T4 high speed tool steel manufacturers and suppliers, IBC Metal Group supplied in round bar, square bar, flat bar, plate, sheet and wire. Tools steels mainly used for manufacturing tools used in machining plastics, metals and woods. However, tool steels fabricated into the desired shape before they able to use. They have good toughness, wear resistance, machinability and resistance to decarburization.

Contact with us Today!