AISI M35 High Speed Tool Steel is a Cobalt-Type high speed tool steel. M35 steel is on the basis of M2 Steel, but with 5% Cobalt content increased which makes better hot hardness and wear resistance. AISI M35 Steel is suitable for heat treatment up to 66 HRC, and offers excellent cutting performance. IBC Metal Group, leading manufacturer of special steel in China. We do supply ASTM A600 HSS M35, it is a high speed medium-alloyed steel. It also known as HSSE or HSS-E which similar to M2, but with 5% cobalt added, which makes better hot hardness and wear resistance.

Supply Range of M35 High Speed Tool Steel

(M35, 1.3243, HS6-5-2-5, SKH55)

- M35 Steel Round Bar: diameter 2mm – 300mm.

- M35 Flat Bar: thickness 2-20mm x width 10-100mm.

- Steel Plate M35: thickness 2-200mm x width 200-610mm.

- Surface Finish: Black, Rough Machined, Turned or as per given requirements.

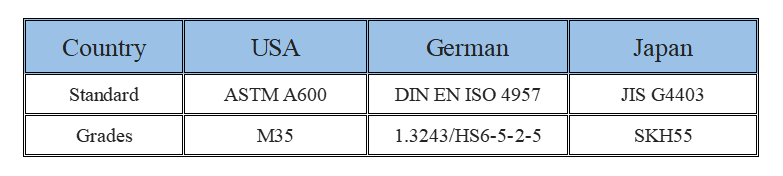

- Relevant Specification of AISI M35 HSS.

Relevant Steel Specification of AISI Tool Steel M35 High Speed

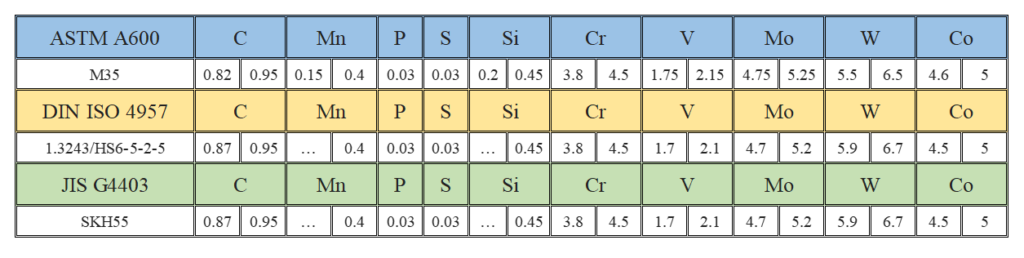

AISI HSS Tool Steel M35 Material Chemical Composition

It has components such as Molybdenum (Mo), Tungsten (W) & Cobalt (Co), Vanadium (V) grades, possessing high hardness, excellent cutting properties, red hardness making it as one of the best fine grade tool steel to generate hardness upto 64-66 HRC post heat treatment.

Heat Treatment

Soft-annealing 850°C – 900°C / 1560°F – 1650°F, slow cooling 10°C / 18°F/h to 700°C / 1290°F, hardness max 260 Brinell. Stress relieving 600°C – 700°C / 1120°F – 1290°F, approx. 2 hours at temperature, slow cooling to 500°C / 930°F. Hardening with preheating in two steps 450°C – 500°C / 840°F – 930°F, 850°C – 900°C / 1560°F – 1650°F and austenitizing at 1050°C – 1220°C / 1920°F – 2230°F. Quenching to about 550°C / 1022°F then cool in air to hand warm. Tempering at 560°C / 1040°F or higher 2 times for at least 1 hour at full temperature recommended.

Machinability of AISI M35 Tool Steel

High Speed tool steel M35 worked in the same way as other high-speed steels by plastic forming, machining, grinding, electrical discharge machining, welding and polishing. M35 tool steel is amenable to cold forming. In grinding, local heating of the surface, which might alter the temper, must avoid. Grinding wheel makers can furnish advice on the choice of grinding wheels. Machining carried out using carbide or high-speed steel tools.

Forging of ASTM A600 High Speed Tool Steel M35

Pre heat the AISI M35 high speed steel slowly and uniformly to 450-500°C and equalise. Then increase M35 tool steel more quickly to the forging temperature of 950-1100°C and equalise prior to forging. Do not allow the forging temperature to drop below 950°C, if this occurs re heating will be necessary. Always cool the steel very slowly after forging.

Application for AISI M35 High Speed Tool Steel

AISI HSS M35 tool steel usually used in conditions with the demand for high hardness. M35 steel suitable for cutting tools such as cutting tools including broaches, milling cutters, reamers, end mills and saw blades. It is also a good quality wear resistant HSS grade for cold work area. Steel M35 also suitable for cold work applications, where exacting demands imposed on wear resistance. The steel possesses an admirable combination of wear resistance and toughness and in these respects superior to the high alloyed cold work steels.

Conclusion

IBC Metal Group Supply & Export M35 High Speed Tool Steel to All Over the World With High Quality and Competitive Price. AISI /ASTM A600 M35 high speed steel is suitable for heat treatment up to 66 HRC, and also offers excellent cutting performance and offers excellent cutting performance. AISI high speed Tool Steel M35 is suitable for broaches, taps, milling, reamers, hobs, shapers cutters, saws ,etc.

Contact with IBC Metal Group