IBC Metal Group manufacture & export 300M Alloy Steel bar to all over the world. It’s a material similar to 4340 with the addition of vanadium and higher silicon content. Alloy 300M offers a combination of toughness and ductility at high strength levels without an increased carbon content. Alloy 300M VAR is Vacuum arc-remelted for excellent purity. It also supplied dual certified to the British aerospace standard BS 5155.

300M is a low alloy, vacuum melted, steel of very high strength. It has a very good combination of strength (280 to 305 ksi), toughness, fatigue strength and good ductility. Applications for 300M steel are those that require strength in the 290 – 300 ksi range, such as aircraft landing gear, high strength bolts, flap tracks, structural applications and airframe parts.

What is 300M?

300M is a “Modified 4340” with the addition of vanadium and a higher silicon content. 300M is a deep hardening steel with excellent torque properties, high fatigue and creep characteristics, and maintains its strength at moderately high temperatures. Meets MIL-S-8844, and others.

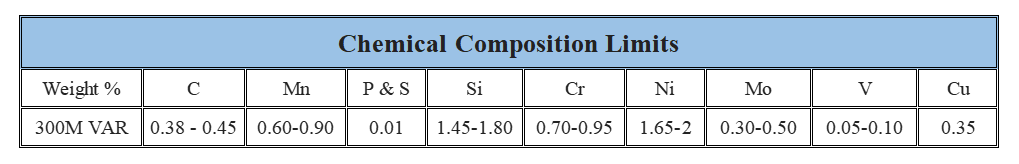

Technical Data Sheet of 300M Alloy Steel Bar:

Typical Mechanical Properties:

Availability:

Alloy 300M VAR (AISI E4340) is available in Round Bar, and Welding Wire.

Welding

300M can be welded by fusion methods or by flash resistance welding. Approved procedures must be used for fusion welding, including pre and post-heating practice, because the alloy will air harden due to heat input from welding. Following welding it is essential to re-normalize or re-normalize and temper prior to the final hardening heat treatment.

Heat Treatment

300M must normalize at 1700 F before hardening. After the normalizing treatment the alloy hardened by heating to 1600 F and oil quenching. Tempering then done last.

Annealing

Anneal at 1550 F and slow furnace cool at a rate of less than 50 F per hour down to 600 F. From there it may be air cooled.

Features:

high strength —— After being quenched and tempered by standard heat treatment oil, the tensile strength of the steel above 1860MPa, which low-alloy high-strength steel with high strength currently in use. High strength can reduce the weight of the parts, and strength has always been the main goal of the design of landing gear parts. The important load-bearing components of American aircraft wings have also adopted 300M steel and used it to a high strength level.

High transverse plasticity —— In the material standard, the transverse section shrinkage rate used as the main mechanical performance index. Which is the characteristic of 300M steel, which is proposed for the characteristics of the use of landing gear parts.

Good corrosion performance —— 1.5% silicon in the composition improves the stress corrosion resistance of 300M steel, which is better than similar steel

Specifications:

| AISI E4340 Modified | AMS 6257 Bars / Forgings N&T | MIL-S-83135 |

| AMS 6419 Bars / tubes | AMS 6417 Vac Melt Bars / tubes | MIL-S-8844 Cl3 |

| BMS-7-26-Cl1 | CE-0896 | DMS-1935 |

| GM-1012 | LC-05-1190 | BS S155 |

300M Alloy Steel Bar (4340 Mod) Applications:

This grade used high strength structural applications with sections 3.5” in and under in cross-section thickness for through-hardness requiring minimum Rockwell C hardness 52 HRC that are subject to exacting magnetic particle inspection standards.

Applications include:

- Aircraft Landing Gear

- Airframe Parts, such as Flap Tracks

- Missile Components

- Motorsport Applications

300M Consumable Electrode Vacuum Remelted Steel is 4340 Alloy Steel modified with the addition of Vanadium and higher Silicon. Carbon Content in AMS 6417 Carbon content is 0.37% to 0.43”. Specifications AMS 6419 requires 0.40” – 0.45% C and AMS 6256 0.40% – 0.44%C. Service Steel Aerospace stocks material with restricted carbon content to certify chemistry to these various specifications.

Conclusion

Essentially it is a modified AISI 4340 steel with silicon, vanadium and slightly greater carbon and molybdenum content than 4340. IBC Metal Group could produce & export all kinds of special steel. And cut them into pieces available. Length according to your requirements. Other sizes may be available on request.

Contact with IBC today!