ASTM T5 high speed tool steel is one of special steel. It belongs to ASTM A600, together with T1, T2, T4 Tool Steel etc. They also in T group in ASTM A600 standard. AISI T5 high speed steel contains Cobalt with range 7.0~9.5%.

IBC Metal Group, a manufacturer and supplier of AISI T5 high speed tool steel offers it in round bar, square bar, flat bar, plate, sheet and wire forms. This steel has superior high temperature performance and toughness than ASTM T4 steel. Notably similar to T4 steel materials, T5 tool steels are used for cutting tools and turning tools. The cobalt content of 8% enhances the temperature performance and toughness compared to AISI T4. Additionally, these steels have high abrasion resistance with excellent cutting performance. After quenching, the surface hardness reaches up to 68-70HRC.

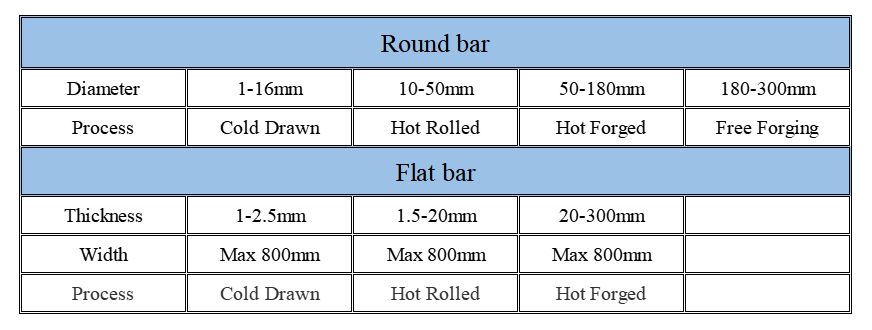

Supply Range of T5 High Speed Tool Steel

- T5, 1.3265, S18-1-2-10, SKH4

- T5 Steel Round Bar: Diameter 1mm – 300mm

- Steels Flat T5: Thickness 1 – 300mm x Width max. 800mm

- Steel Plate T5 : Thickness 2-200mm x Width 200-810mm

- Surface Finish: Black, Rough Machined, Peeled, Turned or as per given requirements.

Supply Form & Size & Tolerance

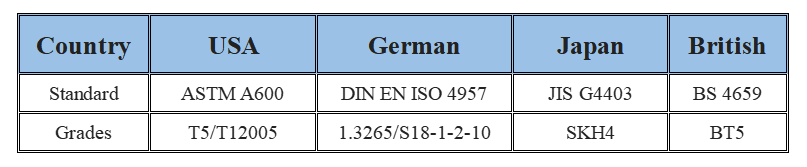

Relevant Steel Specifications of AISI T5 Tool Steel

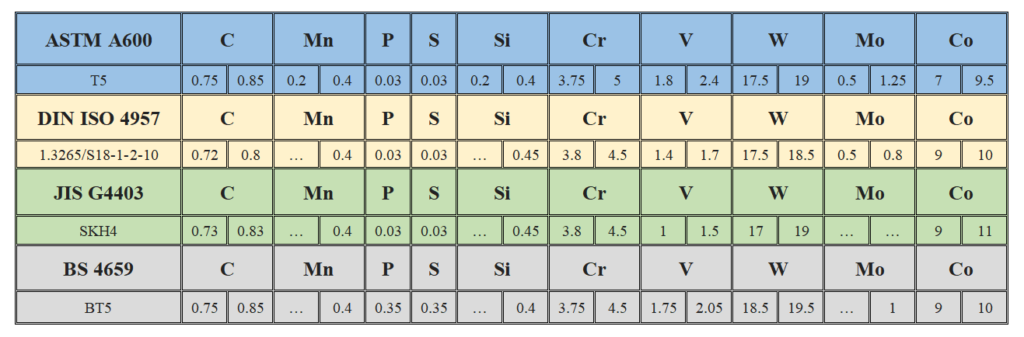

AISI T5 Tool Steels and Equivalents’ Chemical Composition

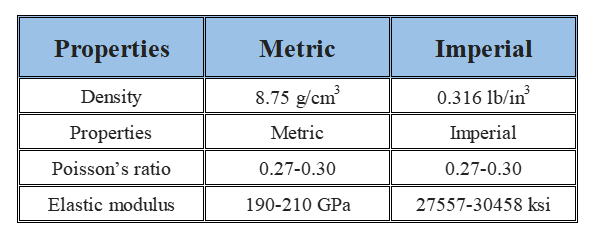

Mechanical Properties of HSS T-5 Steel

Forging of ASTM T5 Tool Steel Materials

Hot forming temperature: 1150-900℃.

ASTM T5 Tool Steel Heat Treatment

- Annealing of T-5 Steel —— Annealing is recommended after hot working and before re hardening

- Heat the temperature to 850°C at a rate of no more than 220°C per hour. Hold at the temperature for one hour per inch of thickness (at least two hours). Cool slowly in the furnace or in air to ambient temperature. The resultant hardness achieved should be Max 255HB or lower.

- Stress Relieving —— Stress relieving to remove machining stresses should be carried out by heating to 600-650℃, holding for one hour at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

- Hardening of Steel T5 —— Preheat T5 tool steel slowly to the temperature of 820-870°C.

- Heat to the final hardening temperature of 1250°C and make sure the material must be heated through.

- Quench in the warm oil, and then complete the quench in air. (care must be taken at this step)

- Tempering of T-5 Steel —— Tempering temperature: 550-590℃.

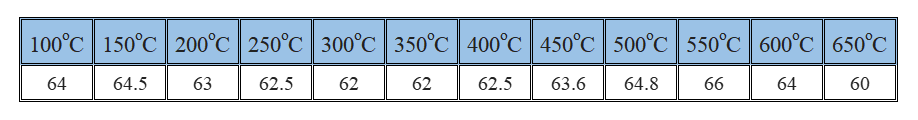

Tempering Temperature (oC) vs. Hardness (HRC)

Applications of ASTM/AISI T5 Tool Steel

Typical applications are: Drills; Milling Cutters; Thread Cutting Tools; Knurling Tools; Cold extrusion punches and Broaches etc. ASTM T5 high speed steels is good for machining high strength steel, high temperature alloy, titanium alloys, casting alloy materials and other difficult-to-machine materials. And also widely used in cutting tools, broaches, extrusion punches, punchers, turning blades, metal working blades, milling cutter, drill,and etc.

Conclusion

IBC Metal Group is one of the best T5 steel manufacturers and suppliers. We producing & export all kinds of special steel. T5 High Speed Tool Steel, one kinds of special steel. Supplying it in round bar, square bar, flat bar, plate, sheet and wire. Huge range of supply range. High quality and competitive price. For more information, please contact with us.

Contact with us!